In its original form, it is a tool that analyzes the results of spectral or colorimetric measurements in the cloud. In its basic form resembles many of the long-standing systems that reproduce the quality of reproduction. However, advanced add-ons make it very similar to many others, and it is unique and unmatched.

The flexibility of grouping measurements gives you a field for calculating the wariations. This extensive module allows you to precisely determine the precision (stability and reproducibility) of all your printing devices.w An analytics of achieved goals allows you to describe the printing conditions, which in turn allows you to compare print substrates, printing machines and operator work.

The data received is invaluable in identifying weak points in the technological chain, but also allows you to obtain very valuable information about the press that we are planning to purchase.

The Print Inspector builds a basic picture of the entire process. It is also an environment in which additional specialized tools such as the Curve Inspector function, which accurately calculates from the current production of co-modifying printing presses (such as G7 and TVI)

Curve

Inspector

Instrument

Inspector

ACCOUNTABILITY

Inspector

NIP TOOL

Inspector

Plate

Inspector

Substrate

Inspector

Environmental

Inspector

Fountain

Solution

Inspector

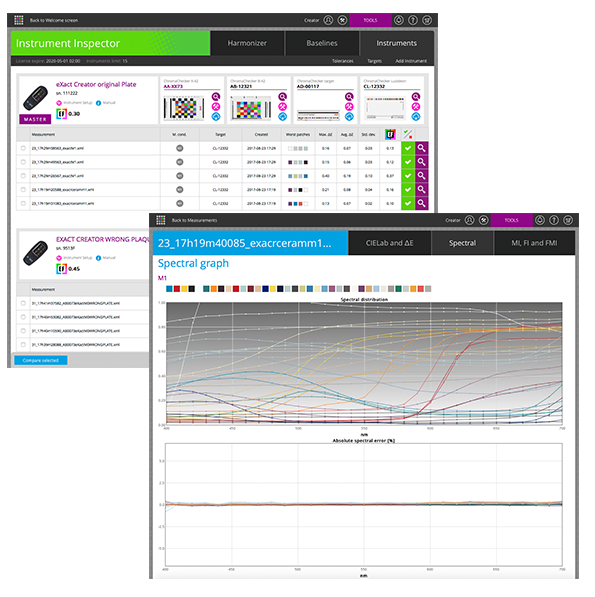

In the real world, measuring instruments do not give the expected precision, especially in different workflows, different models are produced, different manufacturers. What manufacturers declare is often far from what the numbers indicate.

The Instrument Inspector tracks the correctness and reproducibility of measuring instruments, creates documentation of stability and repeatability, but at the same time, with unique features, the Harmonizer allows to largely compensate for these differences so that eventually all instruments within the institution measure as similarly as possible.

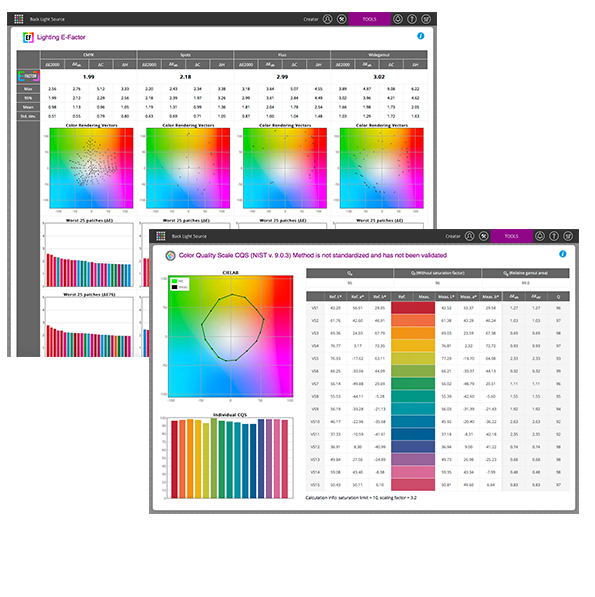

In fact, not only documented verification and auditing in accordance with ISO-3664, but also additional parameters (Lighting-Efactor, CRI, CQS, CRI2012) In conjunction with the Color Inspector, you can precisely select selected color palettes (corporate color sets) under specified lighting conditions. Interchangeability and data sharing will allow remotely comparing lighting conditions.

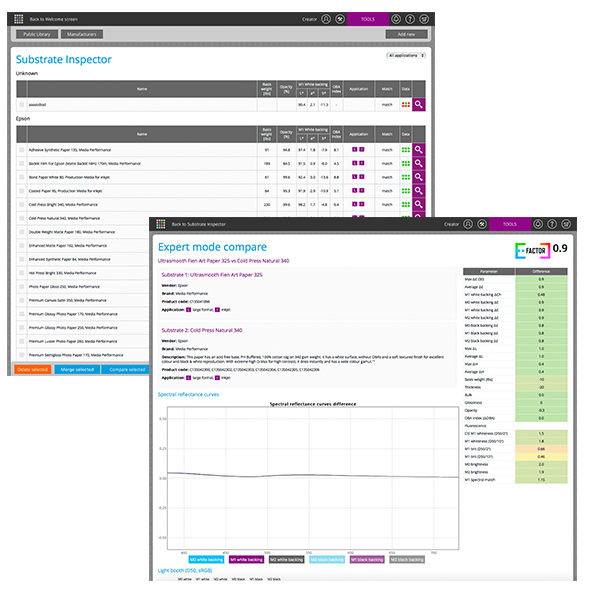

Paper is often underestimated in the printing processbut in fact in the typical four CMYK process substrate is a fifth color. Considering that most of the process printing ink is transparent - it's a paper-like printout that is difficult to overestimate.

The tool has tremendous potential for analyzing different paper characteristics based on a variety of measurements (spectral under different conditions and physical). The resulting substrate description is the basis for analyzing the consistency of the supply, but also allows for advanced search of similar substrates (match function). This is of great importance, for example, in the selection of proofing paper to obtain a high degree of compatibility with the production paper.

Contemporary methods of color definition, color characteristics, the need to translate a variety of color description systems have inspired us to create a narrative dedicated to collaborating, converting individual colors, palettes and color libraries. Support for the latest standards like the CxF / X4 format is crucial for monitoring, for example, packaging production.

Color Inspector goes on - allows you to exchange color information from different industries. A sample of fabric, paint or plastic can be transferred or compared to any other.

In addition to the connection with the ICC Profile Inspector, you can analyze reproductive opportunities based on process or hi-fi printing. In turn, the connection to the Lighting Inspector allows you to simulate color shifts according to the lighting conditions.

The Curver Inspector is available in two independent varints - based on the TVI (dot gain) method and the gray balance based G7 method.

Both inspectors can use production measurements to create compensation curves. It is possible to define an Initial curve to apply an adjustment to the correction - this will allow the current correction without the need for dedicated printi run.

The Curve Inspector G7 can be based on 64 patches of the PI-64 belt - in many cases it will have a place on the production sheet. In addition, Virtual Print Run allows you to simulate curve applications which eliminates the extra print run. For offset presses ChromaChecker has engineered G7 Calibrated Control Bars, which have solids in every ink zone, along with tints and G7 gray finder patches spread throughout the remaining

patches.

For Digital Presses VI-816 test chart measures accurete variations and brings excellent G7 calibration.

It is well known that climatic and environmental conditions have a major influence on the printing process. It is known that alcohol evaporation depends on temperature. The impact of moisture on the ink is known by the paper, it is known that humidity affects overprints. Many processes where electromagnetic influence has a critical impact on climate change. Envoromental Inspector through Data-logger collects and analyzes these data in conjunction with quality assessment of the reproduction process.

Regular measurements are not just spectral analysis - they give a statistical picture of how the process goes, the comparison of machines, the technology paths, press and printer operators are an exceptionally beneficial side-effect of measuring data being intentionally collected.

Platesetter is one of the most desirable devices in the entire technological chain. Despite its high visibility, a place where lack of control can cause difficult problems. Documented measurement allows for predictable quality also here.

Accountability management addresses the problems of operators by assigning them simple tasks and reminding them to do so, while giving managers a clear picture of the practical implementation of technological solutions.

The tool not only analyzes every single ICC profile, enumerating a number of parameters that provide a quality image for the profiles (Gamut, Black Generation, Volume, G7® Gray Balance, TVI curves, RoundTrip Error), but also compares profiles to each other. The tool works in CMYK and Hi-Fi. It is an auxiliary tool for Print Inspector.

Offset presses and other devices where movable cylindrical metal-rubber NIPs (e.g. ink units, fountain solution units, cylinders) will effect tha way the ink, wetting solution or rastered image transfer. Accurate measuring of the NIP width of the NIP pressure are very useful for solving machine problems