) Accountability Inspector

Automatic alert when no data received

2019-01-31

It is imperative that output devices, measurement instruments and light booths should be proactively checked to ensure the devices are operating as expected in order to minimize any waste due to changes in the process. Printers need to transition from Graphic Arts companies to Print manufacturers which eliminates a "break/fix mentality," where the operators just run until something breaks before they fix it.

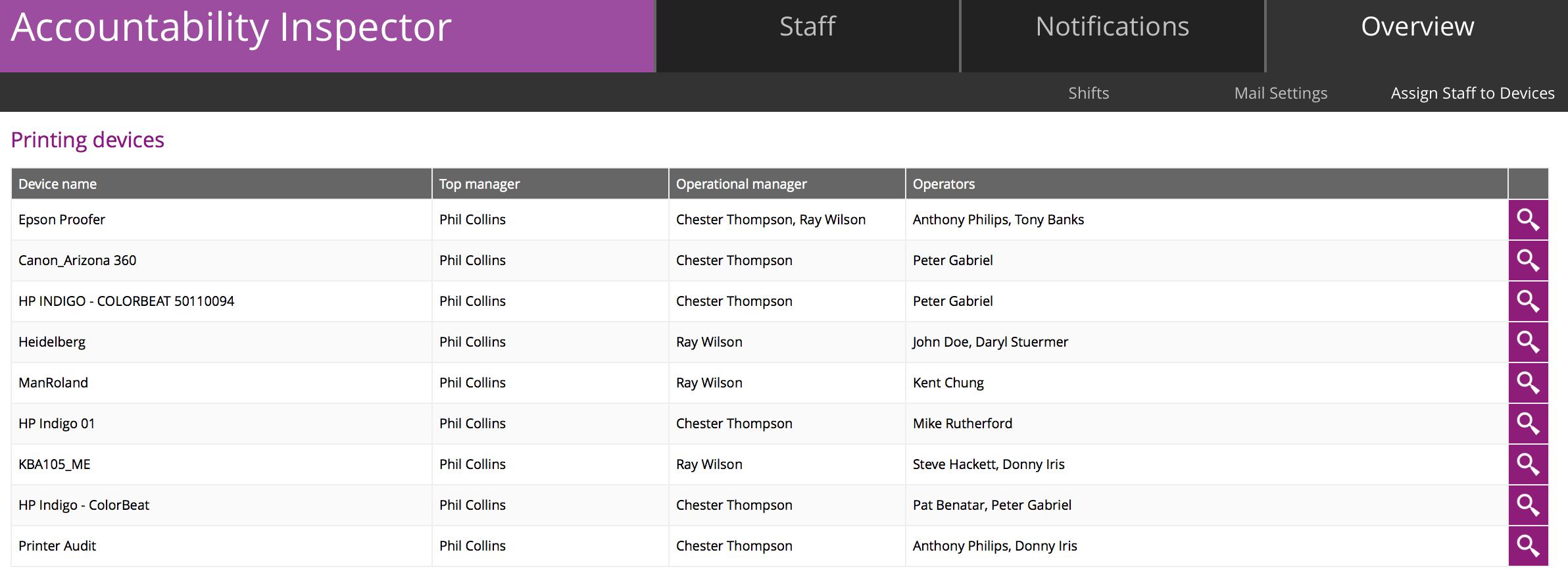

This is a screen shot showing how the Accountability Inspector can be used to assign different operators and managers to all devices that need to be maintained.

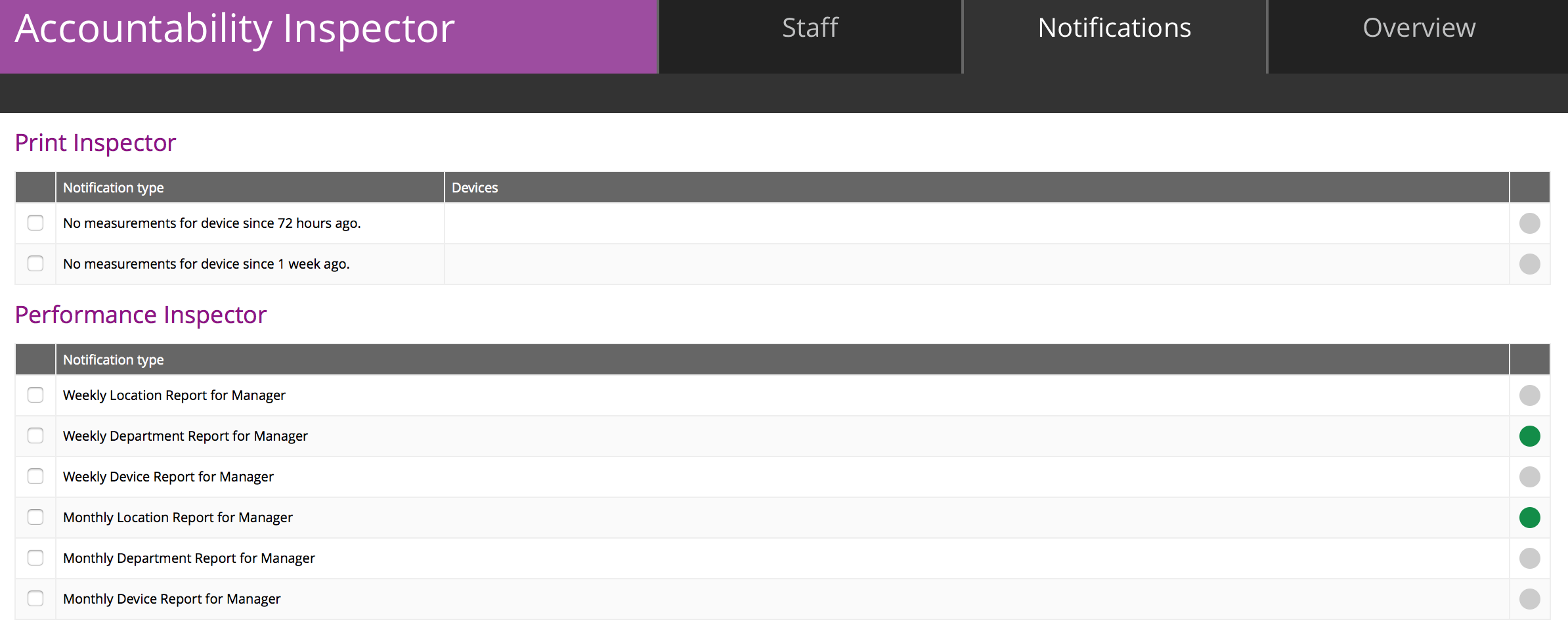

This is a screen shot showing how the Accountability Inspector can be used to automatically send out notifications to responsible users of the system to check given device.

This transition moves to a proactive assessment process where instead of never sending instruments back to factory, or blindly changing light bulbs once a year, this process has operators checking their devices regularly (once a week/month/quarter) to know that devices are operating correctly. If printers are not uploading data, the operator and manager will be notified that no data has been uploaded within the allocated amount of time.

EEnvironmental Inspector

Export data from Environmental Inspector

Export data from Environmental Inspector (CSV)

LEARN MORE ›››LLighting Inspector

Compare measurements in Lighting Inspect

You can now compare up to 5 measurements in Lighting Inspector!

LEARN MORE ›››#General

Color Quality Conference, 2024

"Everyday Color Management Practice" - Next year's color conference is in the planning stages to ensure we deliver top content that can be practically implemented the day you are back in your office.

LEARN MORE ›››#General

Tips for Interpreting the Print Data

Watch the Webinar from the series “Second Tuesday”

LEARN MORE ›››sSubstrate Inspector

Add "Lot" information for Substrate Insp

Add "Lot" information for Substrate Inspector

LEARN MORE ›››)Accountability Inspector

Customizable Color Code - Weekly Reports

Customizable Color Code - Weekly Reports

LEARN MORE ›››