ASSETS: ICC Profiles – manual

This section of Assets brings very important information for measurement evaluation. Target Aim Values are extracted from an ICC Profile. Designers create graphic layouts using an ICC profile. Separation are made by conversion to an ICC profile; pdf files are managed with color management engines where an ICC profile is a core source of information about colorimetric values. Instead of using theoretical values from characterization data set Chromachecker system is based on what current workflows (Image Editing Software, Graphic Design Software, RIPs, Color Hubs, etc.) practically uses - ICC Profiles.

ChromaChecker Print Inspector uses CGATS21_CRPC6.icc instead of CRPC-6.txt. On the same principle in the case of FOGRA.txt, we need ISO Coated v2.icc.

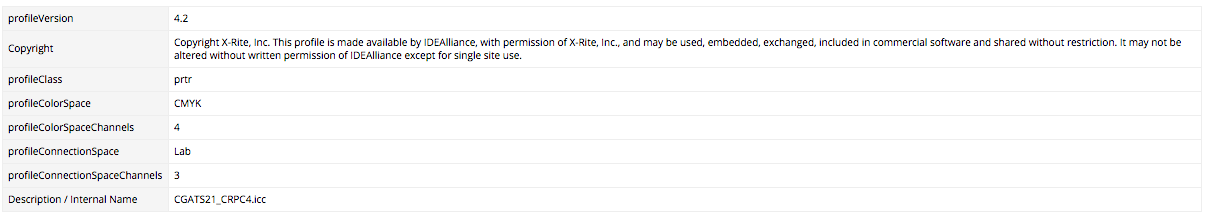

Extended profile description

ChromaChecker database collects not only ICC files but also some additional information related to it:

- Characterisation data set - data sets initially used for profile creation (e.g. CRPC-6.txt).

- G7® compatibility - we want to know is profile was designed for G7® calibration method

- Backing (if measurements were captured on black or white backer) In most cases white backing was used but not in all). If you capture IT-8.7-4 test form on Image Control by default scan is made on black console! Most current common characterization data sets are white backing.

- The coordinates of the substrate in an opposite backing. If captured data comes from white backing measurements – the system will expect colorimetric coordinates of the substrate on black backing. It is necessary if for example production measurements are captured on black background (e.g. Intelli Trax, Image Control...) – and ICC profile is white backing (e.g. CGATS21_CRPC6.icc) for additional SCCA recalculation.

- Measurement conditions used for data capturing - It is important to remember that different measurement conditions can produce quite different readings, especially when substrate contains a large amount of OBA's. (high value of Fluorescent Index or OBA Index). Be sure to use the same measurement condition for both measurement and target values.

- TVI curves ( C, M, Y, K) - As defined in PSO (ISO12647-2) for TVI calibration method is required to specify target densitometric curves. In ISO standard, there is a set of predefined curves. In case of G7 calibration method, those fields can be skipped

- Source - We collect information about profile vendor/creator and where the profile comes from - we expect a link to the vendor's web-site.

- Description - in many cases, there is additional information published by the provider about an actual print condition, and e.g. settings for the black generation policy, total ink limit, etc.

Public (ICC Profiles) Library

We offer easy access to a variety of standard profiles. Data are organized by subdirectories - ordered by the vendors. Go to Public Library, select proper Directory, select wanted files from the list and press "Import" button. From this moment, all imported profiles are available in "My ICC Profiles."

ICC Profile Library features:

Profile built-in info

ChromaChecker is extracting some critical informations from a profile:

Profile custom info

Data edntered by the user can be displayed:

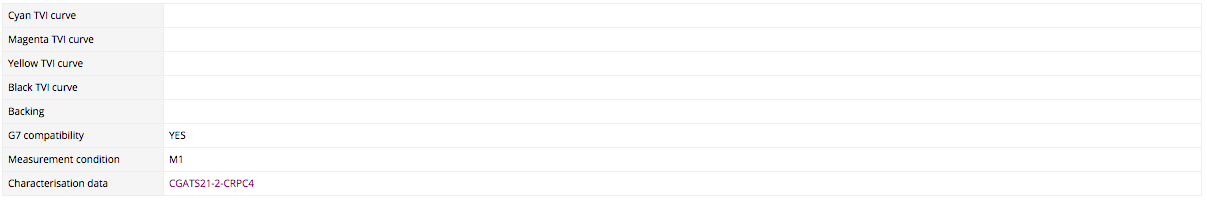

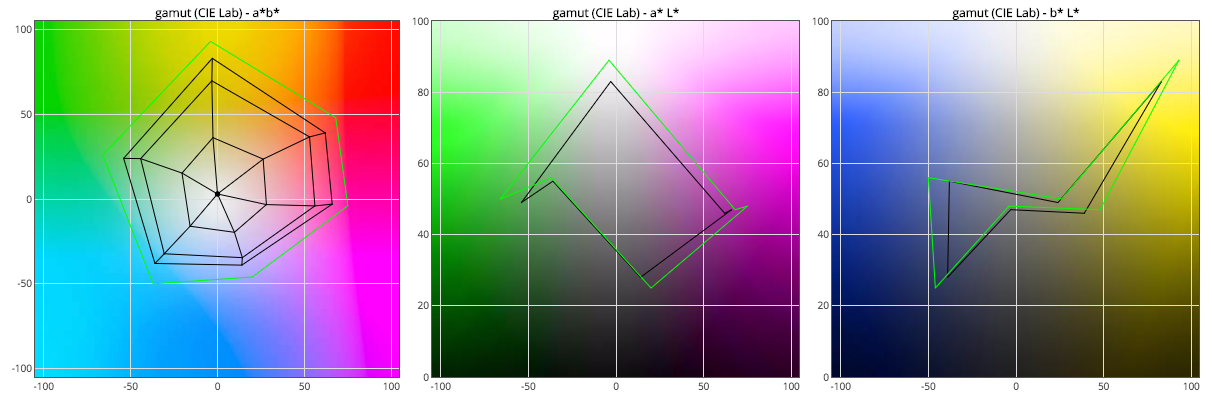

Gamut

Gamut of an ICC Profile is displayed in L*a*b* color space (black lines). Green line shows data from Characterization data Set used for Profile creation (in compare tool proper option has to be seleted first)

![]()

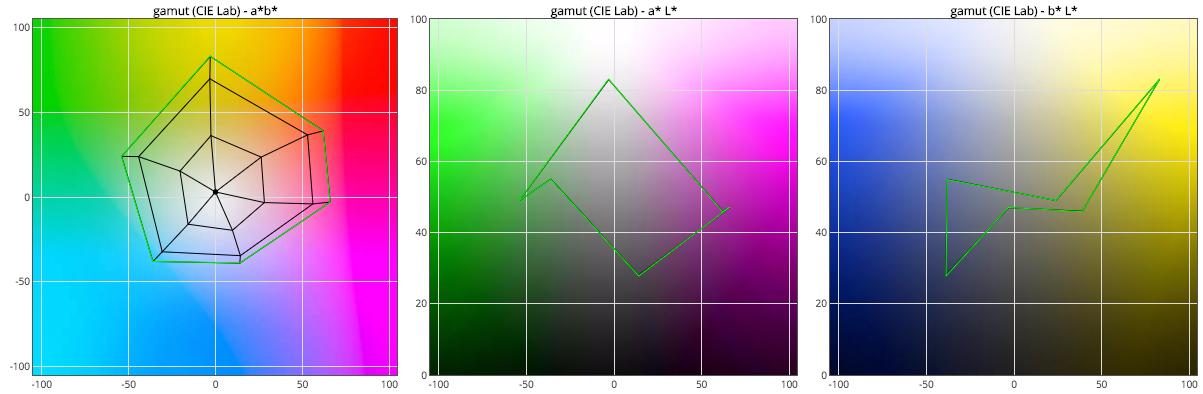

TVI

ChromaChecker extracts colorimetric TVI / dot gain curves for each primary color. By moving cursor over curve a detailed information are displayed. Data are ploted as graphs as follow:

It happen that data from Characterisation Data Set are not smooth (green line). In ICC Profile where data smoothing have been applied curves become smooth with no bumbs.

Patches

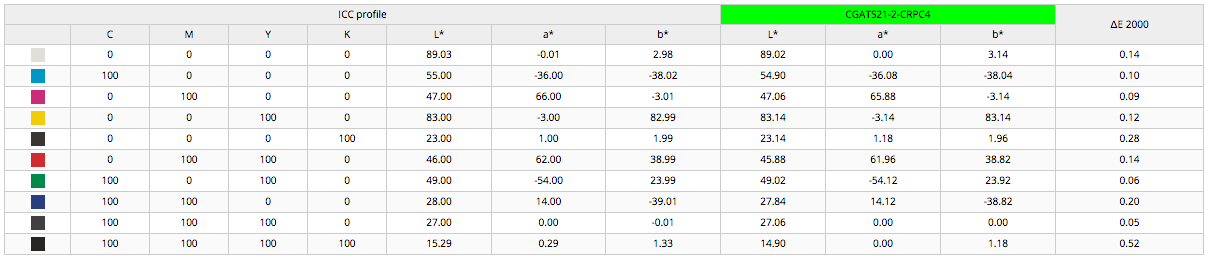

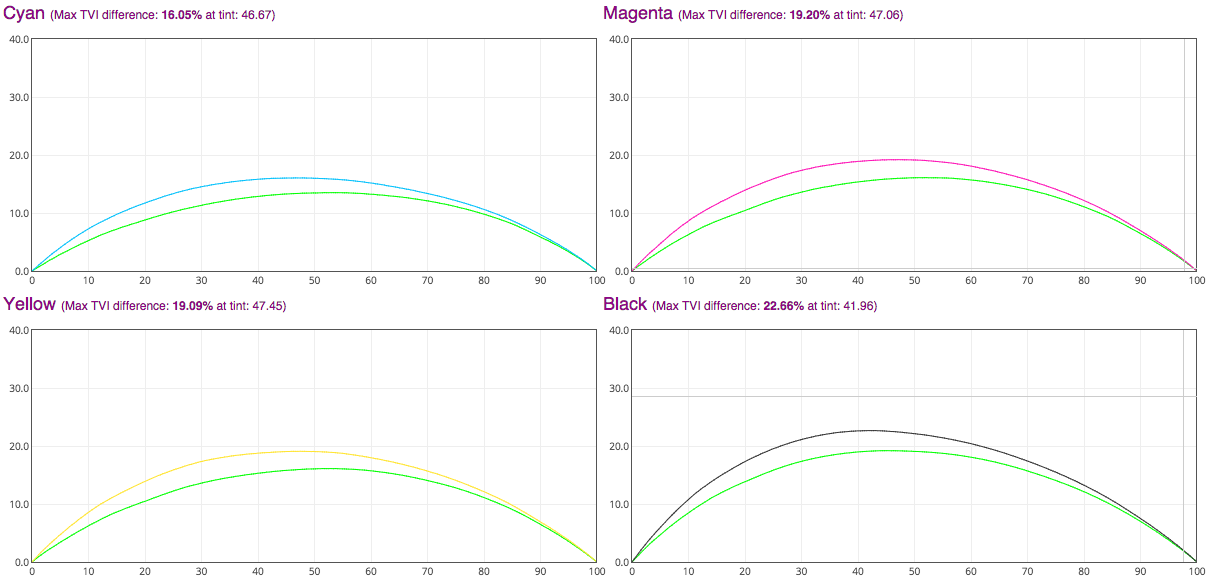

Colorimetric coordiates for substrate, primarieries and overprints are compared in the table

ICC Profile E-Factor

Values from an ICC Profile are compared to Charcterization Data Set used for profile creation. E-Factor is calculated as ∆E 2000 of 95 percentil of all compared patches.

Compare

By changing settings of compare tool a comparision with other ICC profile can be made.

![]()

Gamut

TVI

Patches

ICC Profiles ChromaChecker related tools:

Match ICC

This unique tool is available from the top menu bar for any measurement file or group of files. In a normal way, all measurement are compared to an ICCprofile that is connected to the Track. This function checks if any other profile will provide a potentially closer match. All ICC profiles in Public Library are also used for this comparison. It might happen that current ICC profile doesn't reflect actual Print Conditions, and accuracy can be improved by correction of the system settings. For this calculation, E-Factor is displayed.

PC qualifier

Unique tools for optimizing number of ICC profiles that can cover a selection of substrates. For given ∆E difference, an optimization procedure compares the difference for set of patches. Software returns number of suggested groups and the most representative substrate for each group. This tool is recommended mainly for LPF devices and helps to reduce an amount of ICC profiles in all cases where small ∆E can be accepted. Thanks to this user can save time on profiling and optimize productivity.

Profiling Data Qualifying/Optimization Procedure.

We know that in many cases when an ICC profile is made, captured data are inconsistent. If for example IT-8.7-4 chart is printed and scanned many times it can quite often happen that variations can be very high, and due to that questioning profile creation. Few common reasons:

1. The instrument is not working correctly, due to the mechanical problem or too small patch size. ( We have documented cases where the same printout measured several times on the same instrument can produce variations of 3∆E - and the reason is a little bit too small patch size (accepted by instrument driving software!)

2. Print are made on the press not well maintained. Intra-page and inter-page variations are very high and color coordinates are different depending on a location on the sheet or pullout from print-run.

3. Printing device, substrate or other conditions are not stable and repeatable (e.g. nozzles in printing head of ink jet printer use to clogged and unclogged randomly, or blanket in digital press randomly losing some dots in highlights).