|

|

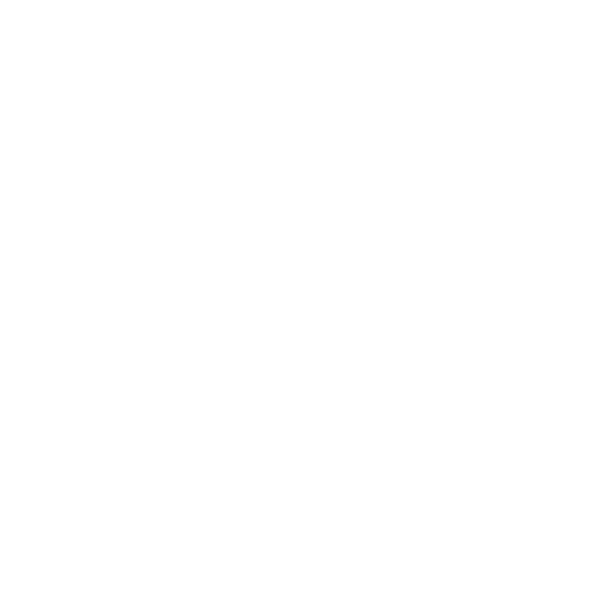

ChromaChecker – 5 steps to Color Conformance

|

1. Standard |

2. Benchmark |

3. Adjust |

4. Track |

5. Integrate |

|

|

|

|

|

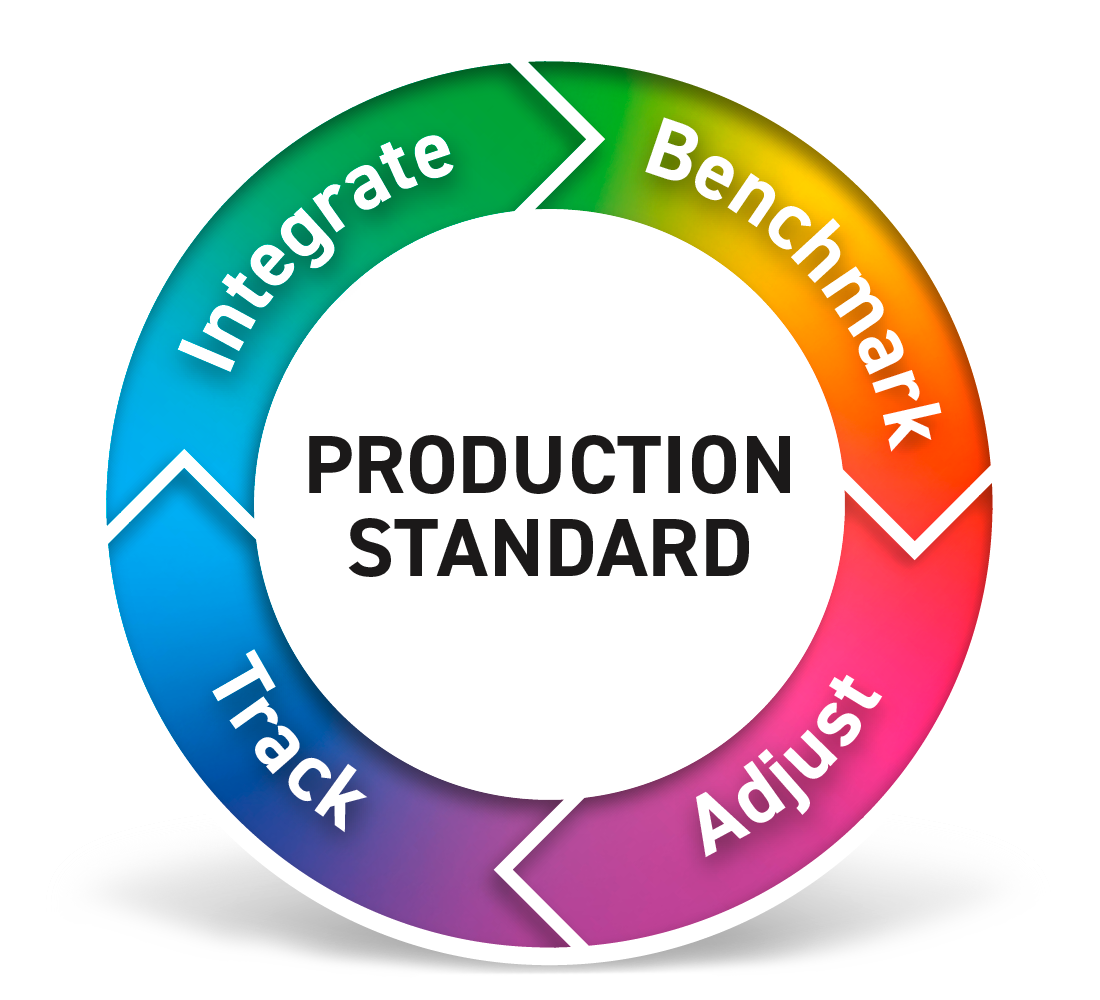

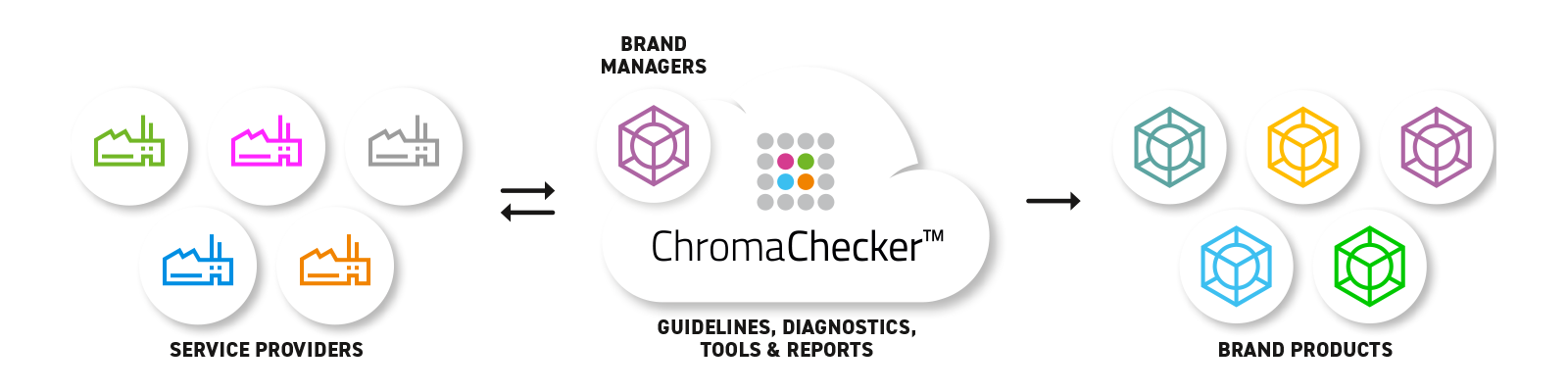

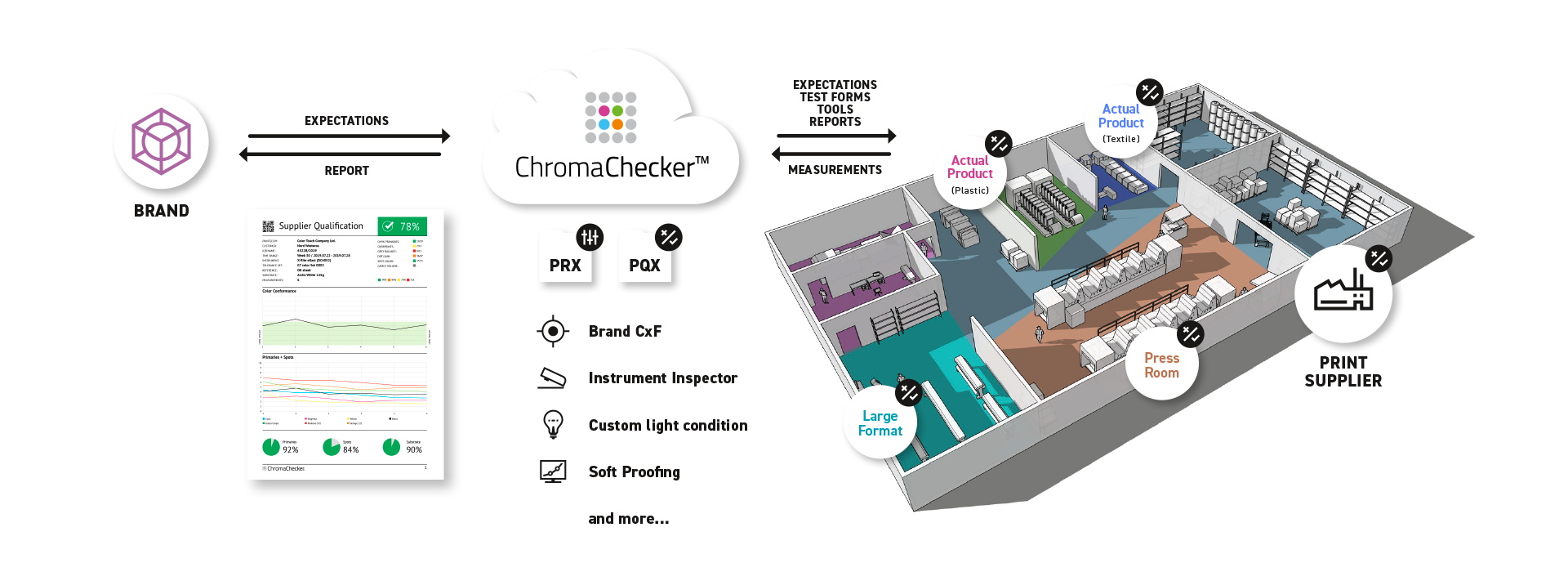

Print Buyers are using ChromaChecker to provide a simple dashboard for reporting on color quality. This is about setting and monitoring your expectations for print production and having a centralized method for communication quality standards as Pass or Fail. The ChromaChecker platform tracks the precision and accuracy of all printing devices for consistency and accuracy to industry standards such as GRACoL and for even tighter tolerance, set custom targets based on specific work. The dashboard shows real-time pass/fail results regarding process and spot colors based on agreed-upon expectations. Image showing "Welcome Screen" Dashboard

ChromaChecker stands out due to its ability to add value for production by providing operator guidance as well as color experts to maintain consistent and accurate results. This approach makes the Print Buyer and Print Service Provider true partners in the design through the production process by achieving shared goals. Providing centralized libraries and analysis tools in the form of Inspectors for print devices, lighting, spot color, object color, environment, substrate, ICC Profiles, and G7 Curves streamlines the common variables in the print process.

Highest Quality Tolerances

When the highest level of tolerances is required, ChromaChecker helps production environments monitor results by reporting on all the aspects that need to be maintained including achieving the highest level of color tolerances. In addition, tools are available to provide efficient solutions for simple tasks such as iterating G7 curves, ICC Profiles, Control Strip design, and color lookup tables, to name just a few. While the highest standards are always a priority – the type of work being produced will define the appropriate tolerances. This is made simple using ChromaChecker by identifying the full capabilities of the printing device within known limitations. this coupled with the substrate and material specification provides the tolerances to match the job and pricing model.

Tuning the Complex into Simple

In addition, new materials, lamination processes, specialty substrate, textile all have different capabilities that can be defined and set as an acceptable tolerance. Even physical products that are painted, injection molded, special surfaces can provide color measurement data as well as texture and surface characteristics.

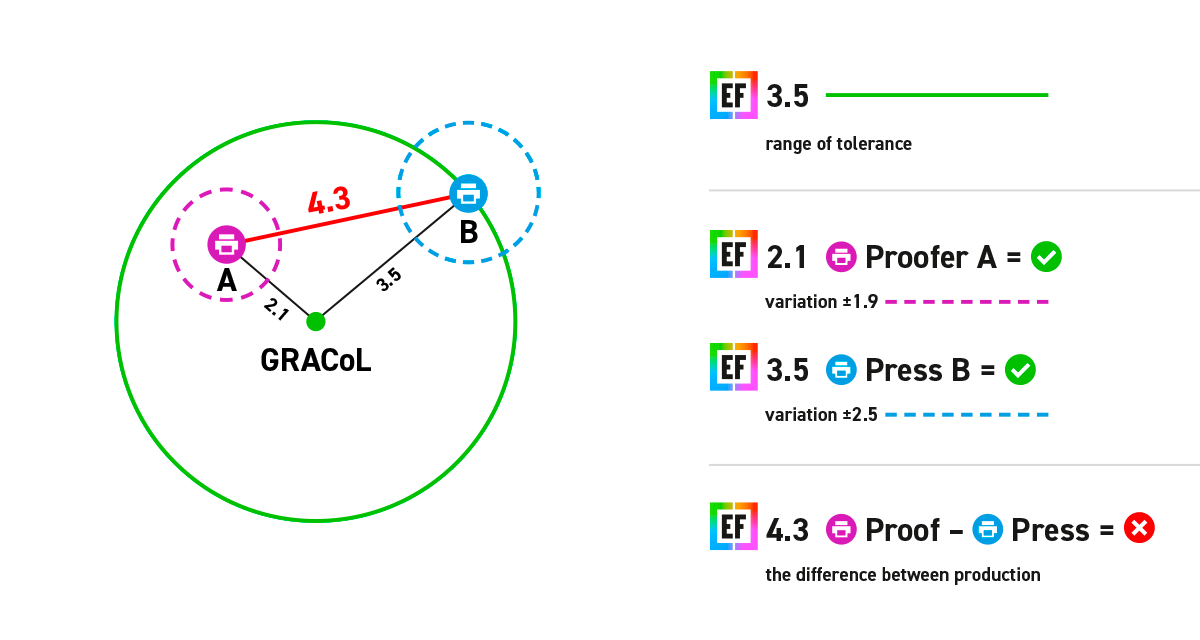

E-Factor

- E-Factor Definition

- Exercise Online & Hardcopy

- Print Inspector Reporting

Most Advanced Color Repository

- Parallel Spectral Color Definition (simultaneous different color specification)

- Full CxF/X-4 implementation (substrate, tints, and opacity)

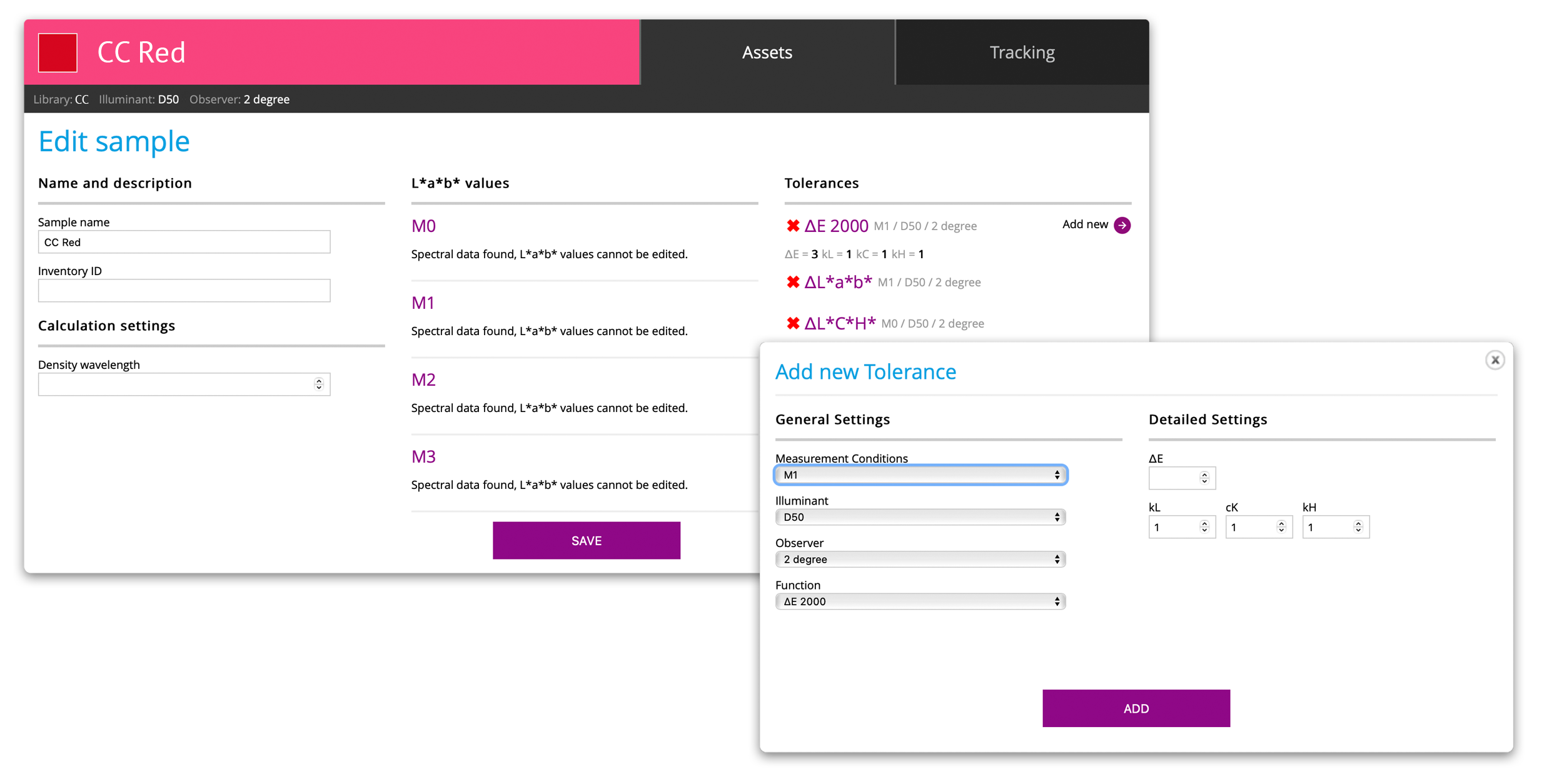

- Multilevel Tolerance

- Process Control Integration - Print Inspector / Sharing Data / Reporting

- Multi-instrument tracking

- Surface and special effects support

- Glosses a Roughness

Supplemental tools that help better manage corporate color:

- Display Inspector - remote display and soft-proofing stations validations and verifications

- Lighting Inspector - Lighting condition control

CC Capture Color Inspector

- Fast and accurate color Library creation with a handheld instrument

- Color tracking (QC) with sample autorecognition feature

- Fast correction color palettes for spot OK sheet

- IO table Virtual Control Strip technology

3rd-party unique integrations

- Spot QC measurements with Barbieri LFP (Virtual Control Strip) for transmissive and reflectance measurements (e.g. flexo packagings printed on a transparent substrate).

ChromaChecker Nano

- Color Appearance

- Surface Structure

![]()

Define/Document Color Expectations

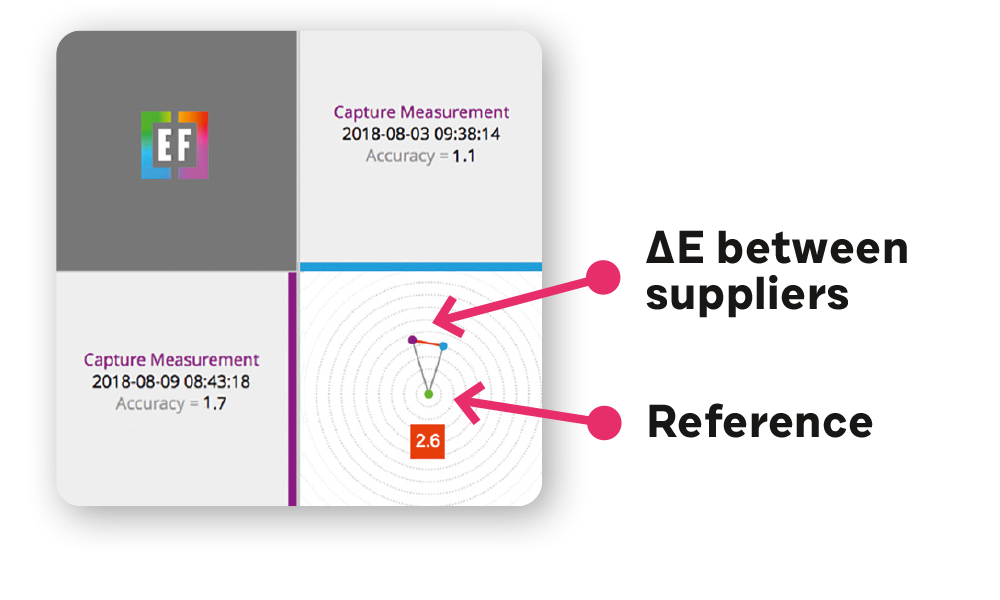

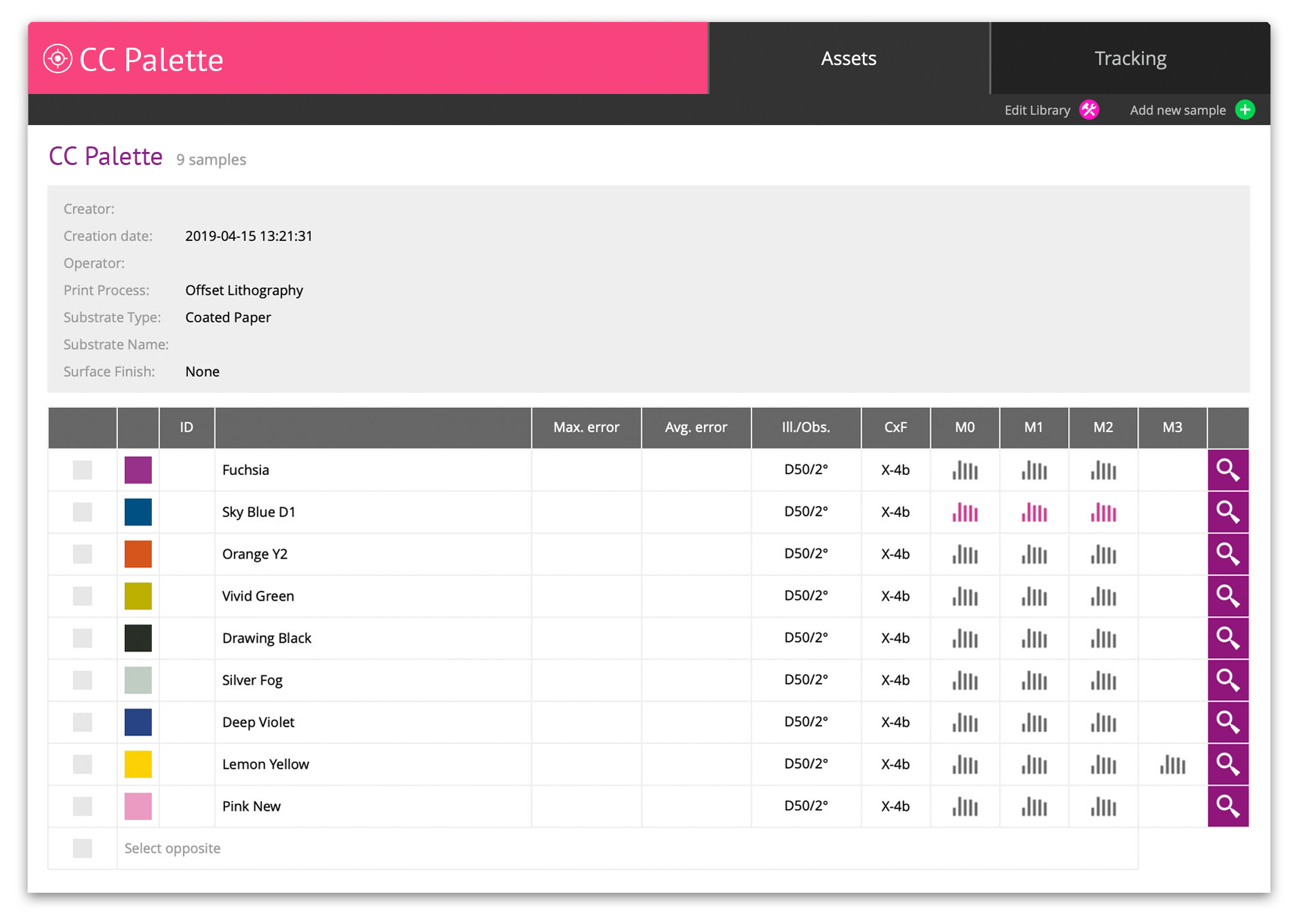

ChromaCheckers’s Color Inspector allows brand companies to create the brand library in spectral CxF/X-4 format that provides the most flexibility when communicating colors to the supply chain. Color Inspector also allows the brand company to set tolerances using an intelligent visual tool that compensates for the non-linearity of delta E and can communicate it in a numeric metric which can be communicated to the entire supply chain.

![]()

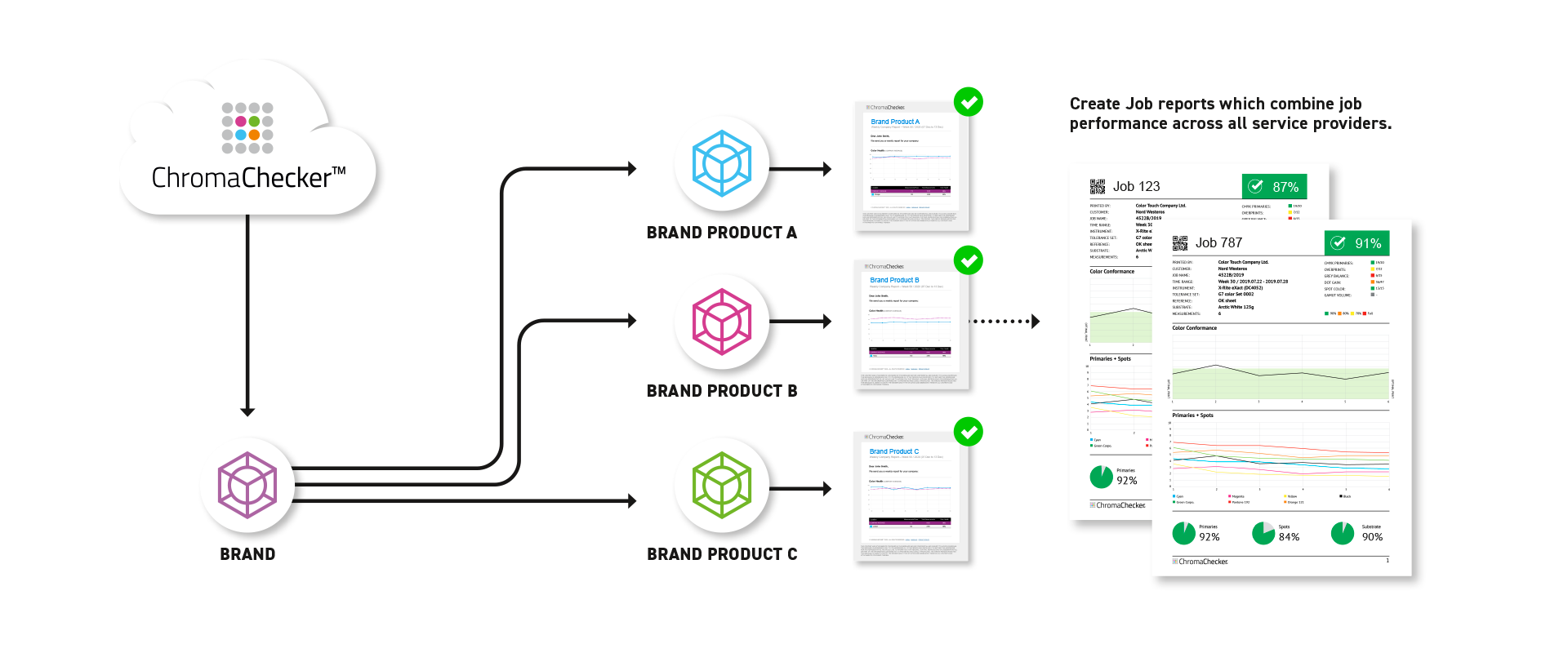

Collect data from suppliers (automatically)

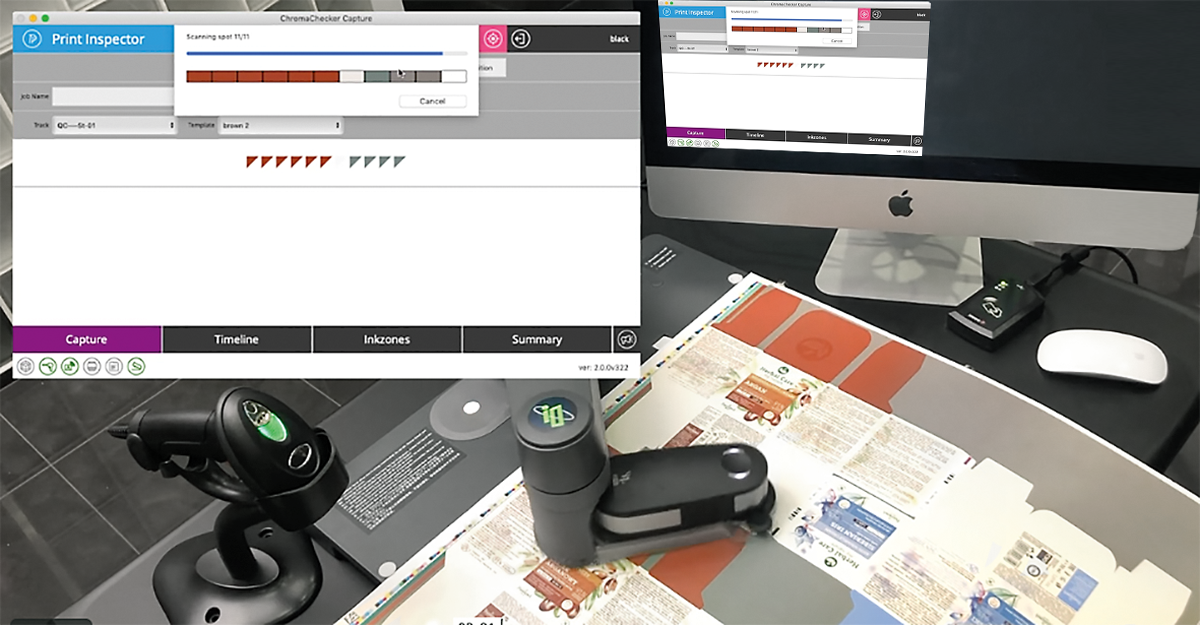

ChromaChecker has multiple interfaces with suppliers workflow which will automatically select only the specific brand's jobs with no intervention from the supplier side. The supplier can use ChromaChecker Capture, HP ColorBeat, or CC Uploader to measure brand jobs which will automatically be uploaded to the brands ChromaChecker account. This eliminates extra time and energy on the supplier side to prove to the brand that they are printing jobs correctly while giving the brand company all the details required to ensure brand conformance to expectations.

![]()

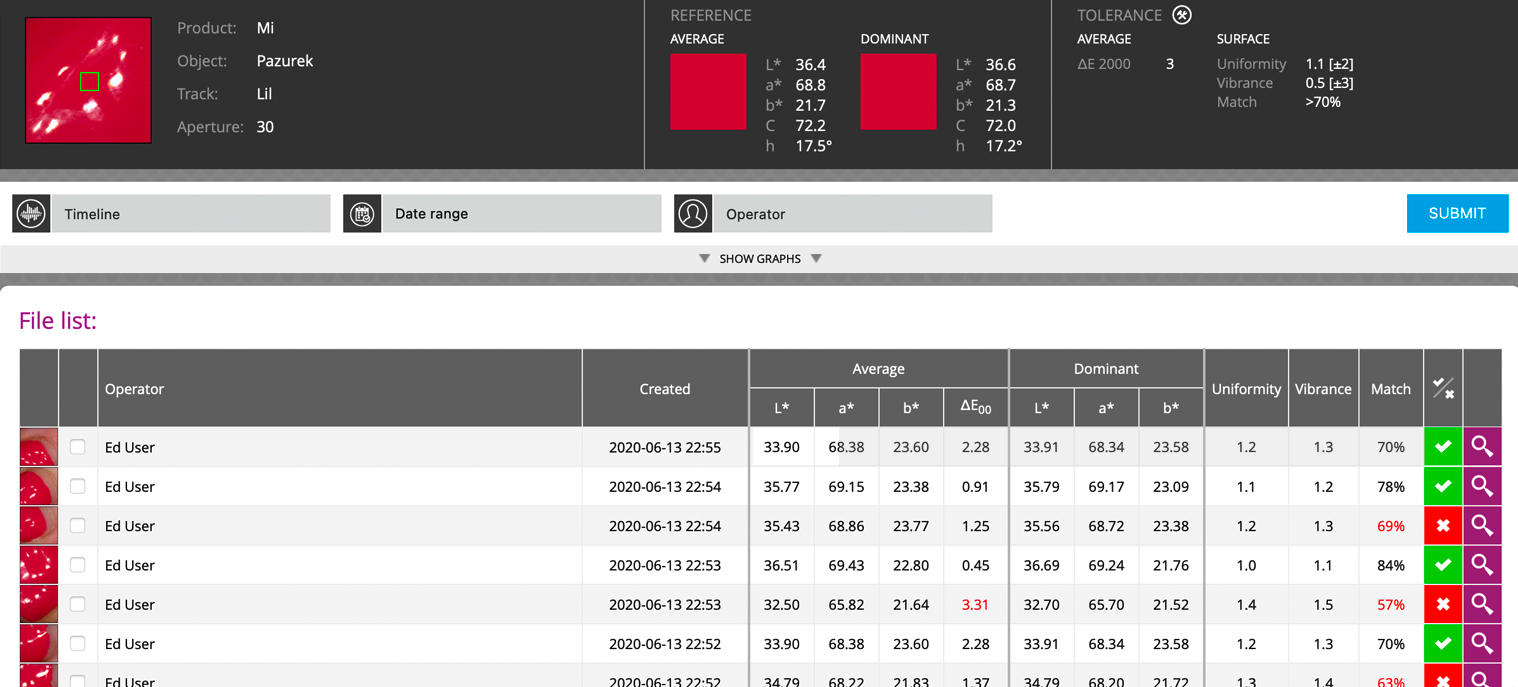

Color Inspector

Works with physical products that have to complement the print.

![]()

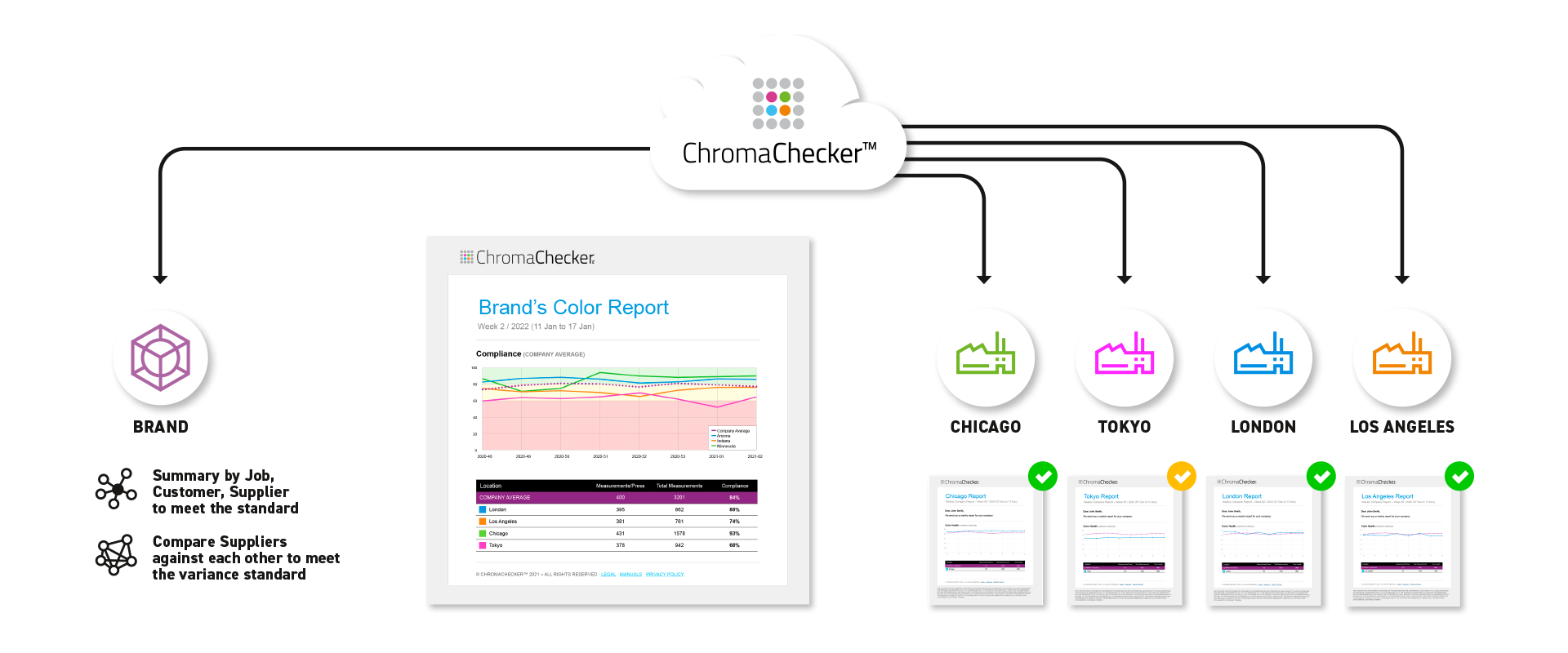

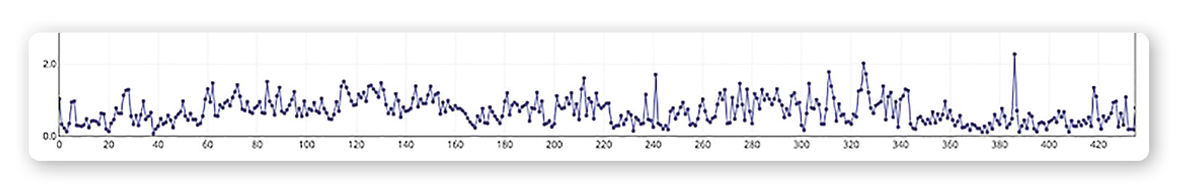

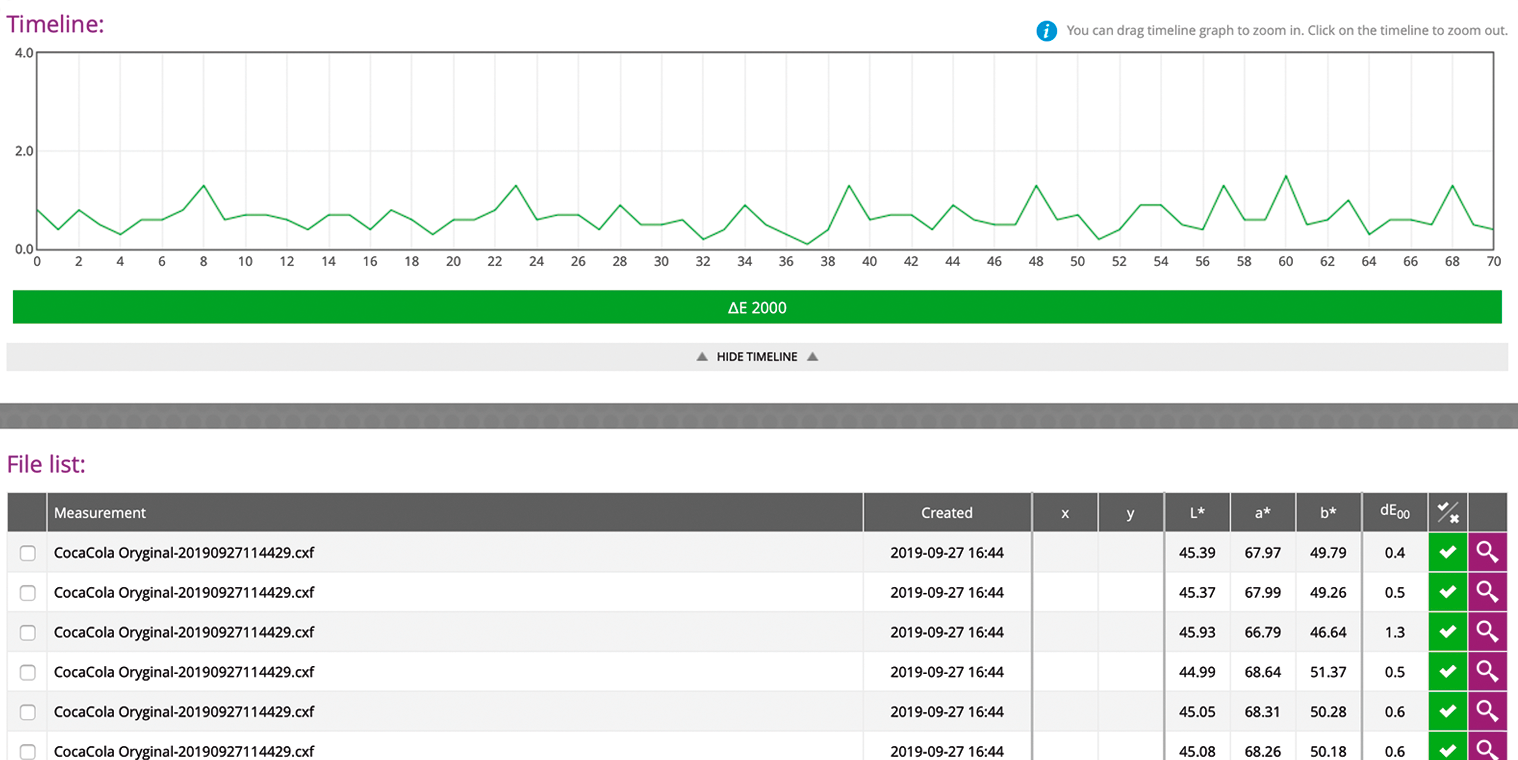

ChromaChecker creates reports showing suppliers performance to brand reference and to one another

Supplier performance to reference on Timeline

Supplier performance to reference on Timeline

|

||

|

ChromaChecker — visual tolerance defined via numbers |

||

|

||

|

ChromaChecker — Central repository for ICC profiles, color bars and CxF libraries |

||

|

||

|

Provide supplier with Capture — Virtual Control strip: measuring actual colors on print job |

||

|

||

|

|