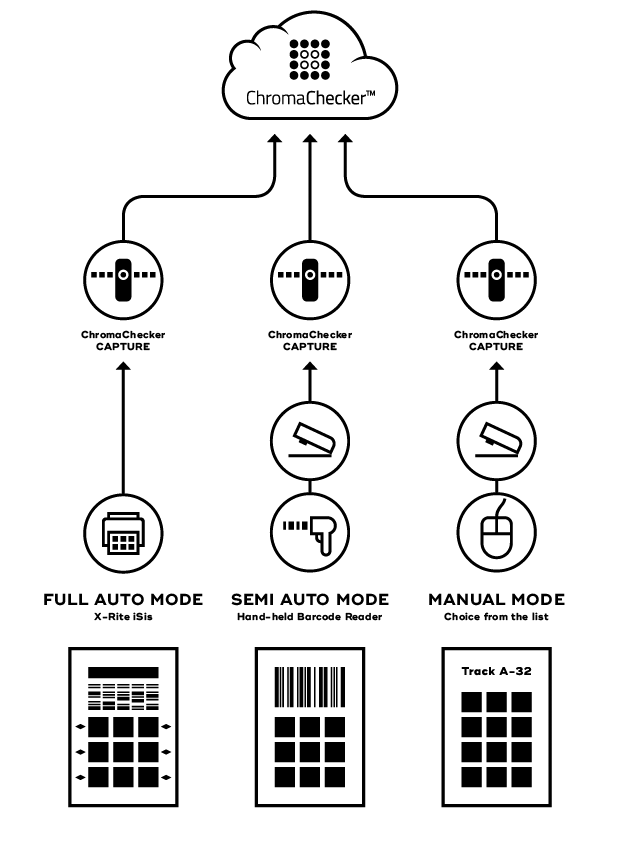

Capture Configuration Options

|

Capture is capable of driving the instrument by selecting the print condition and clicking measure, or automating the process using barcodes. Following are 3 example configurations for Capture. A. Automated solution based on X-Rite iSisIn this configuration, one iSis instrument can perform automated measurements by sensing the paper, starting the scan, reading the barcode, and completing the scan. The operator places the paper in the iSis and views the results with no other intervention. One iSis can be used for dozens of printers in one plant completing the identification of the printer through the use of a barcode. Each print condition (press/substrate) has a unique barcode (which ChromaChecker generates automatically) that is interpreted automatically when the target is measured, and the data is uploaded to the specific track. ChromaChecker Capture driving the X-Rite iSis will recognize barcodes automatically, this capability requires minimal skills from the operator, the printed page just needs to be inserted into the instrument properly, the measurement, the interpretation, and routing of the measurement to the right track is all automatic. A report showing the result of the print is displayed in real-time to help the press operator know if they can start production if the Color Conformance values are within required Expectations (E-Factor).

B. Semi-automated solution based on any supported Instrument driven by ChromaChecker Capture equipped with the barcode reader.Any Instrument along with a barcode reader - like i1Pro1/2 can be used to collect data. The Operator scans the barcode into Capture before measurement. The barcode automatically configures Capture with the correct instrument, color bar, and track, all the operator needs to do is measure the color bar, with no manual choices for the operator. This unique function will improve productivity and upload data in the most effective way possible, eliminating any chance of operator error. A report showing the result of the print is displayed in real-time to help the press operator know if they can start production if the Color Conformance values are within required Expectations (E-Factor).

C. Basic Scan - The press operator using Capture selects the print condition and measures the control stripThis is commonly used in production prior to implementing automation as the manual steps are limited. A report showing the result of the print is displayed in real-time to help the press operator know if they can start production if the Color Conformance values are within required Expectations (E-Factor). |

|

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.