Company and Operator Continuous Improvement Reports

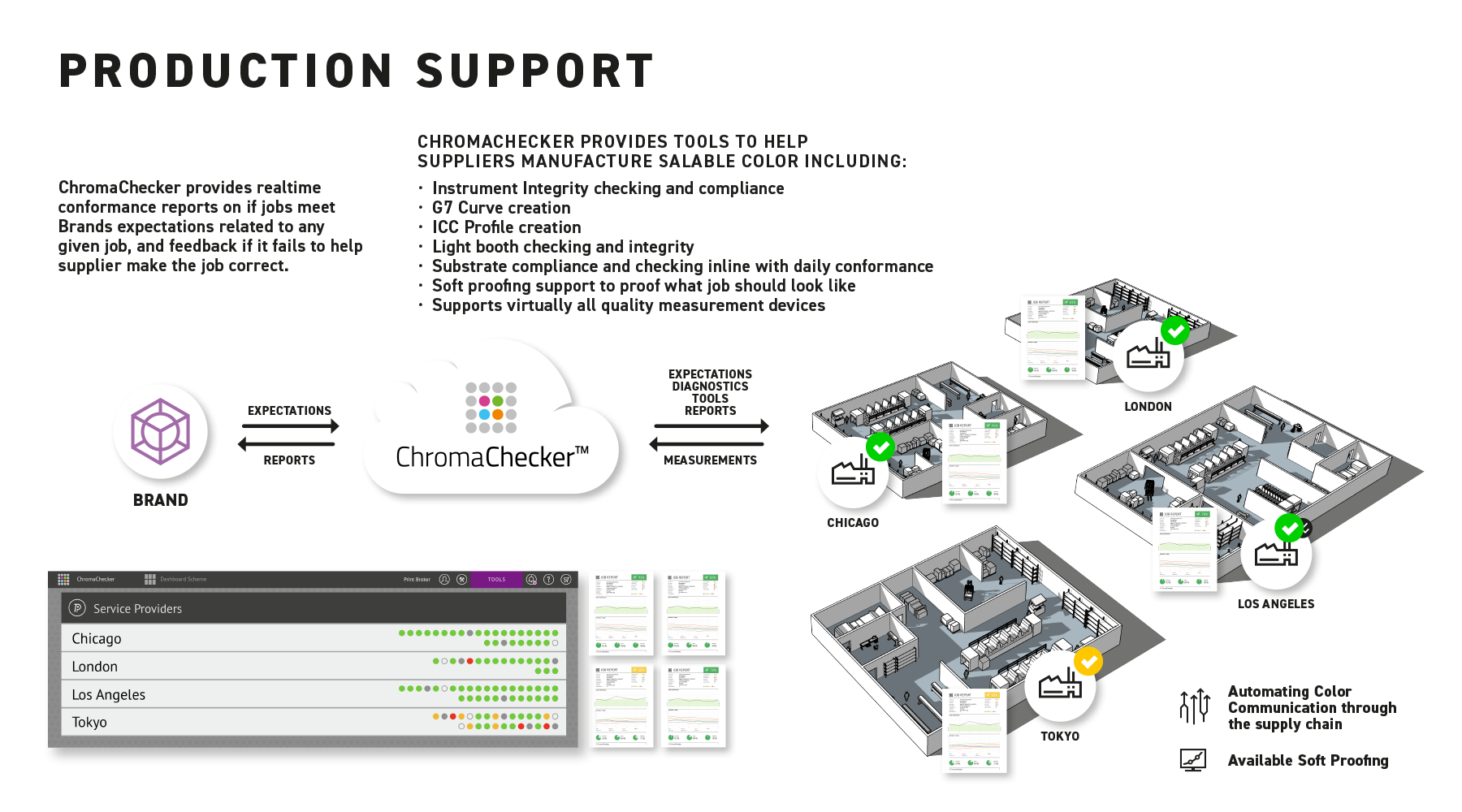

ChromaChecker is unique compared to other products because it is all about making everyone in the print organization responsible for color. Whether your company has 4 or 400 printers, one color expert can not be responsible for all of them. The entire company needs a quality mindset to migrate to a zero waste condition. The only way to implement this is by getting the printer operators involved and trained with a quality mindset.

ChromaChecker is unique compared to other products because it is all about making everyone in the print organization responsible for color. Whether your company has 4 or 400 printers, one color expert can not be responsible for all of them. The entire company needs a quality mindset to migrate to a zero waste condition. The only way to implement this is by getting the printer operators involved and trained with a quality mindset.

Quality Mindset means that as an operator, it may take 3 minutes longer to print a ChromaChecker target and measure it to receive a PASS before you start printing the production jobs. Still, if the printer is not printing correctly (wrong paper, old toner, wrong settings, something broken) and ChromaChecker reports that the printer FAILS Conformance, you just saved the possibility of printing multiple jobs that would have been rejected by the customer and cost the organization time, reputation, money and potential future business with those customers.

Quality Mindset educates the operators within an organization that profit is more important than time. It may take a little more time to print it right versus twice as much time to print it over. Quality mindset educates the operator that 75% of printers in North America make 2% or less in sales. One rejected print run that costs $500 requires the company to make more than $25,000 in new sales. Moving to a zero waste condition is critical to the future of any print company, and operators are on the front line to reduce waste.

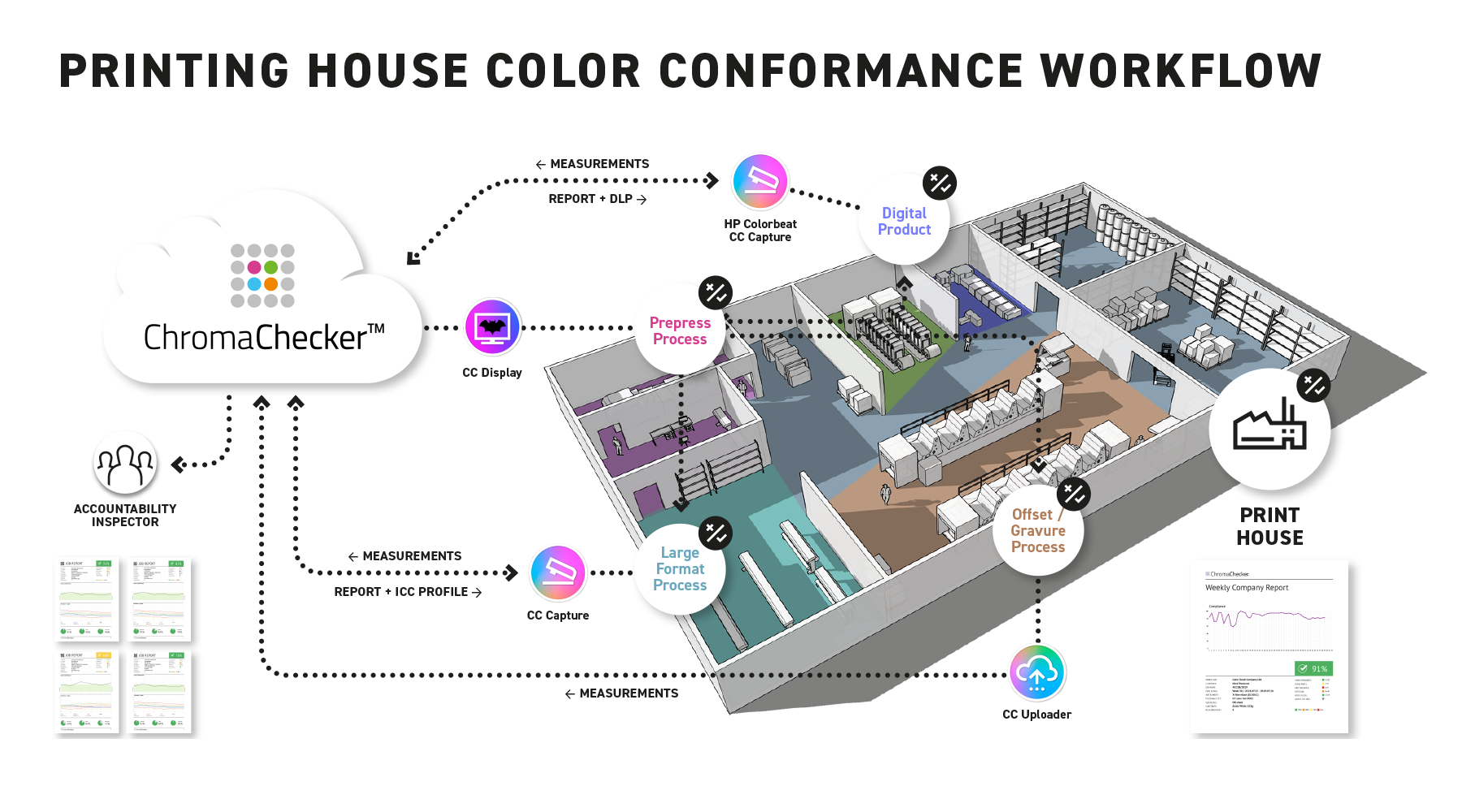

The ChromaChecker Color Conformance platform provides the operators with training to print a ChromaChecker target and measure it with any of ten different measurement instruments using ChromaChecker Capture software. Even if the operator has never used the instrument before, owners of ChromaChecker can access a wealth of training materials related to color management fundamentals and even take classes on Quantify Color and how to print and measure ChromaChecker control strips.

Live dashboard on the production floor

ChromaChecker provides a Print Dashboard which can be positioned on a 70” display for everyone to see how all the printers are performing in the plant. Green is good, red is wrong, and it immediately tells a story of which printers are making money and which are not.

In addition, ChromaChecker can be configured to automatically send reports via email to every manager and operator, showing how the printers within their responsibility performed over the past week or month. These reports show how each operator/manager’s printers performed against the average.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.