Defining references and tolerances

Process Color References:

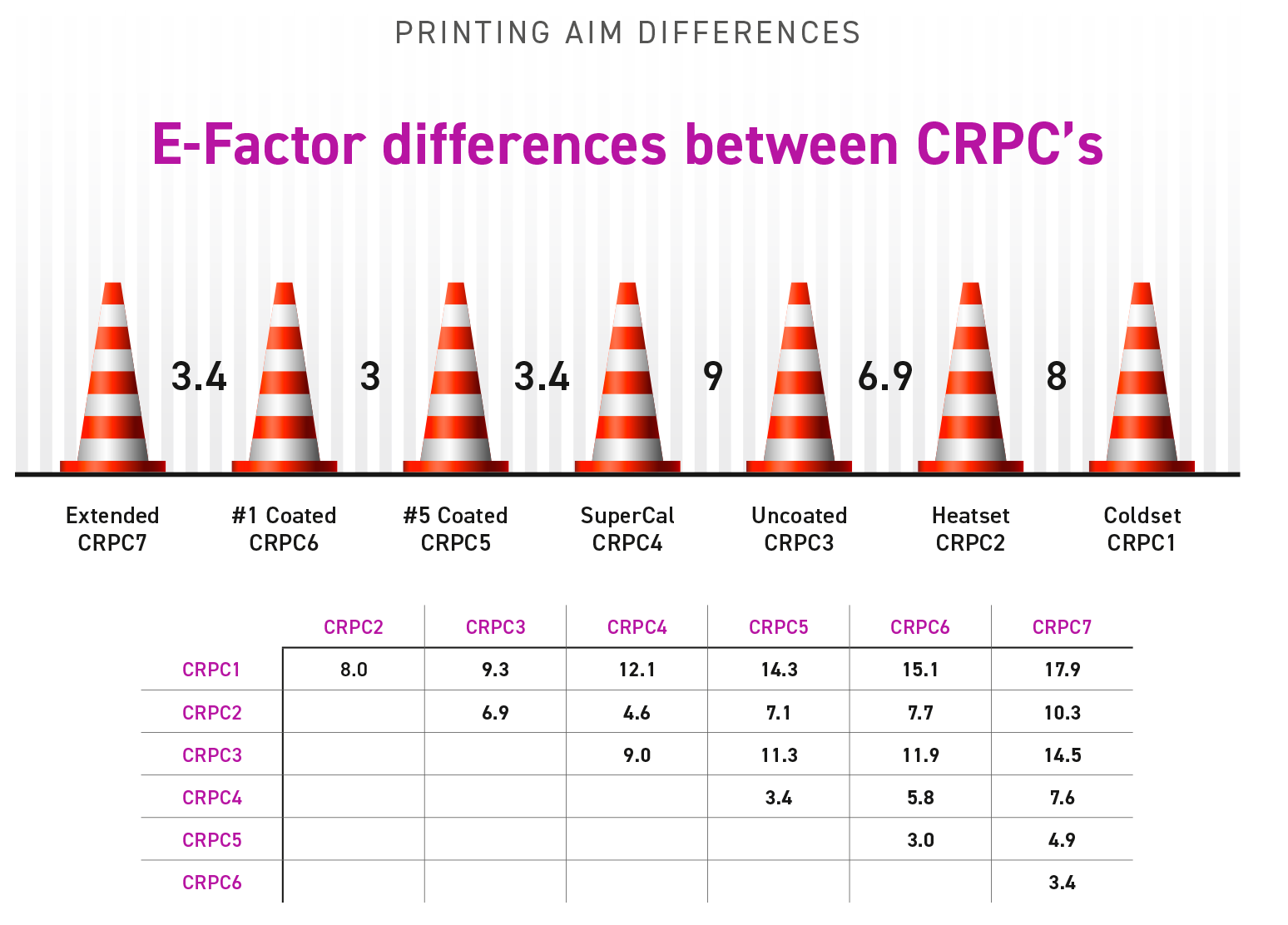

It is important to define references for the type of color process that you are needing to match. When dealing with process color (CMYK printing) it is important to aim for industry standard print conditions based on ISO 12647 print processes and using ISO 15339 printing aims. ISO 12647 provides ink guidance for the colorants of the CMYK inks, and ISO 15339 provides CMYK reference color spaces based on 7 types of printing on different substrates identified as CRPC1 through CRPC7, with CRPC1 having the smallest gamut (representing cold set newsprint on newsprint paper) to CRPC 7 being the largest related to certain digital printing devices.

Common references like GRACoL2013_Coated (based on ISO 12647-2) is CRPC6. Ideally, the printer will want to choose the closest CRPC due to the white and black point of the actual substrate being used on press. If the substrate is within 5 ∆E (00), then SCCA (Substrate Corrected Color Aims) will accommodate for the differences. If the substrate is greater than 5 ∆E (00), then it is recommended that the print condition is can be G7ed for proper gray balance and tonality, and create an ICC Profile representing the actual print condition to provide a close reference for the given condition.

Process Color Tolerances

Assessing if a CMYK process job is within specifications is very challenging. If we review the industry printing press process tolerances like ISO 12647-2, or G7 gray it is easy to have situations where the print passes all the required metrics within defined tolerances, but the visual result is a very poor match. And it is easy to have situations where the metrics for either G7 or 12647-2 fail, but the visual result (matching to proof) looks very acceptable. This is the huge weakness of these process color tolerance sets that most tradition scorecard systems are based on. The problem is that these metrics assess individual attributes that collectively don't necessarily define the visual result. This is why the CRF at the 95th percentile ∆E (00) a metric we coined as E-Factor) is very powerful in assessing the visual result which is what is most important. A lot of scientific research has proven that the CRF at the 95th percentile ∆E shows that most print buyers will accept a 3 E-Factor, and not accept an 8 E-factor, and if the customer's expectations are greater that the printers E-Factor match, the customer will accept it. This is the first time that our industry can determine a customer's color expectations and apply those actual expectations to the print process. We know that all operators, sales people, customer service, and print buyers have difference levels of expectations which can cause a great deal of poor communication and unmet expectations. This E-Factor metric eliminates all of these weaknesses. The limitation of calculating the E-Factor is due to requiring at least 60 different patch values to accurately calculate this metric which is easy if the printer is using a modern G7 color bar with the P2P gray finders included which helps eliminate doing dedicated G7 press runs to update press curves. This process is working with hundreds of customers and providing great results for the customers running this way. Any company assessing their prints for 12647-2 or G7 would be out of business if they only sold passing sheets for these tolerances, but by using E-Factor, the visual results are much more relative to the salability of the sheet, and it compensates for situations where one of the metrics required for 12647-2 or G7 fail by 0.1 ∆E that has no affect on the visual result, but causes a "false fail" related to these two tolerance setting.

Spot Color References

In order to assess spot or brand color tolerances it is necessary to define what the reference color is based on. Reference could be based on a measured physical sample, or some digital reference such as a PMS color or some other digital reference. It is important to ensure the measurement specifications of the reference (M condition, Illuminant, Observer angle) are specified as part of the reference.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.