Metamerism in practice

Lighting greatly affects color matching and how to prepare for potential problems.

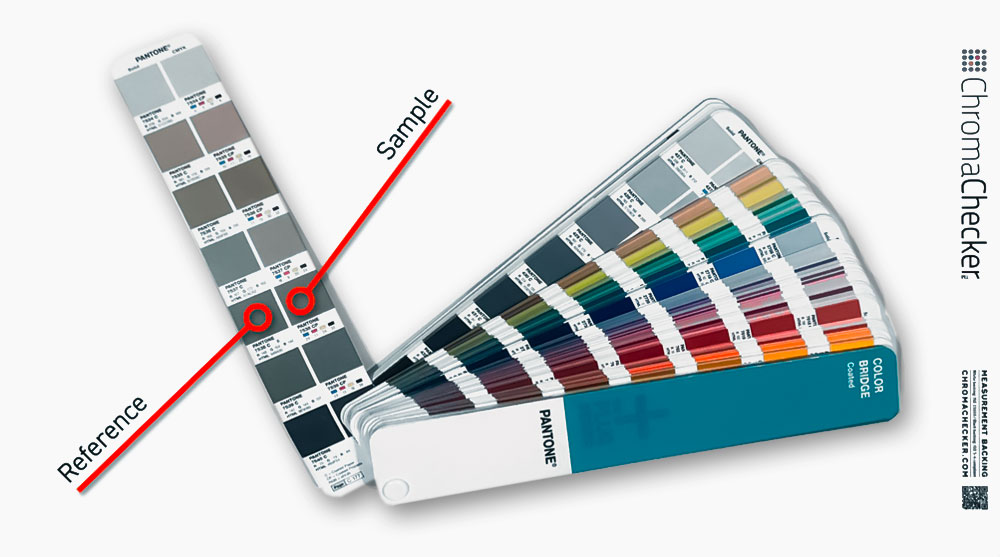

You have been asked to print a job using Pantone 7538 C as a spot color and print a matching companion job using CMYK process printing. Referencing the Pantone Color Bridge Coated Guide, we can get the process equivalent of our spot: 7538 CP defined as 24C, 11M, 24Y, 33K.

The samples are virtually identical when we compare the two samples visually in daylight (D50). But will the colors match in different lighting conditions? Let's analyze it!

The fastest and most efficient way to verify the colors will match under different lighting is to use ChromaChecker Capture with any supported instrument (in this example, we are using the X-Rite eXact).

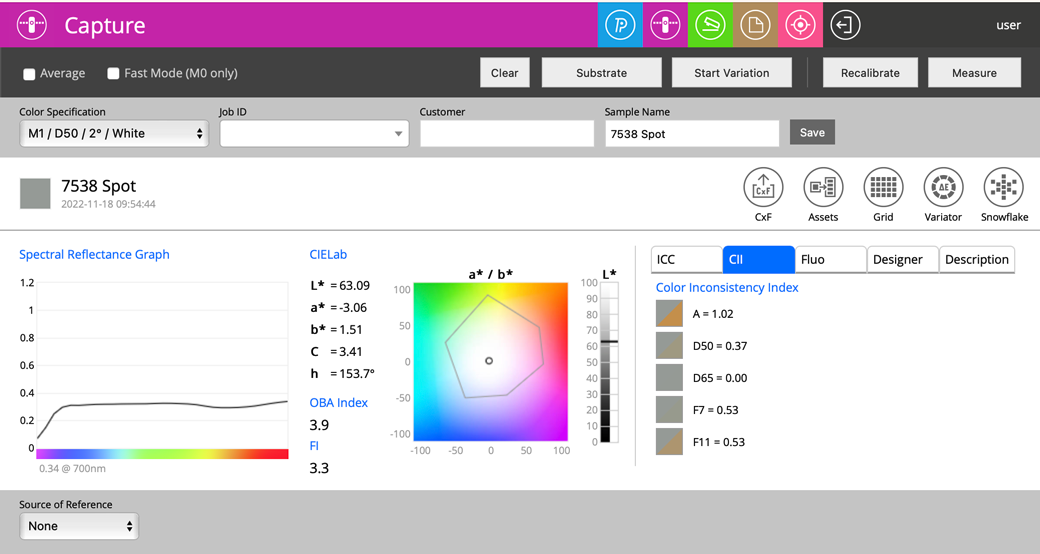

1. Measure the Reference.

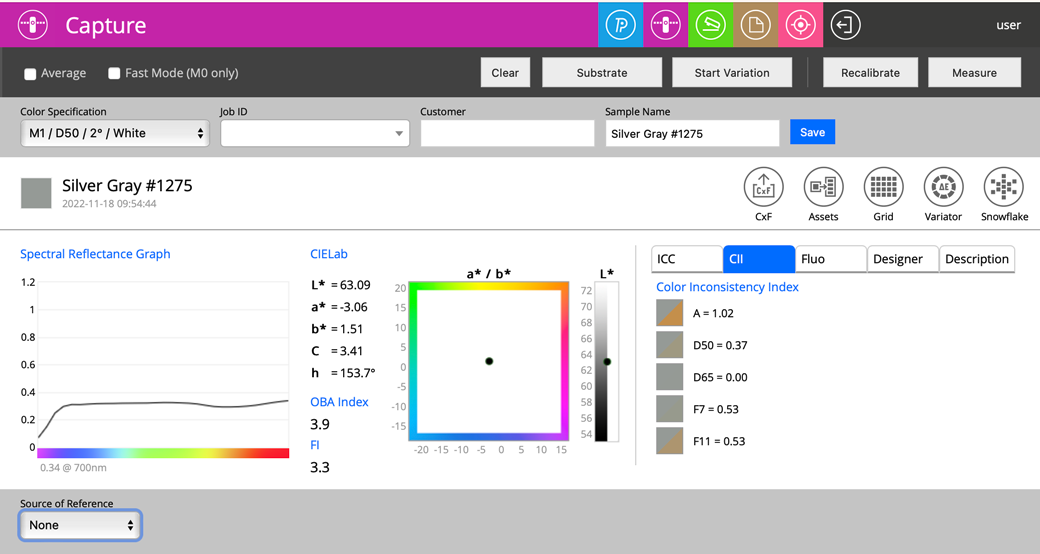

Measure sample: "Pantone 7538 C" (left side in Pantone fan book); the color report shows that the measured sample is printed on the substrate containing OBAs. In the "Color Specification," select "M1 D50 2° White" to be sure that OBAs are properly compensated for. Use an iSO-compliant white backing for measurements.

ChromaChecker automatically names it Silver Gray with a number, but you can rename it "Spot 7538" (optional).

On the screen's right side, find the CII (Color Inconsistency Index) tab. This allows you to predict how the color will change when exposed to different lighting conditions.

For Illuminant A (tungsten lamp): CII=1.02; and for F11 (fluorescent tubes), CII= 0.53.

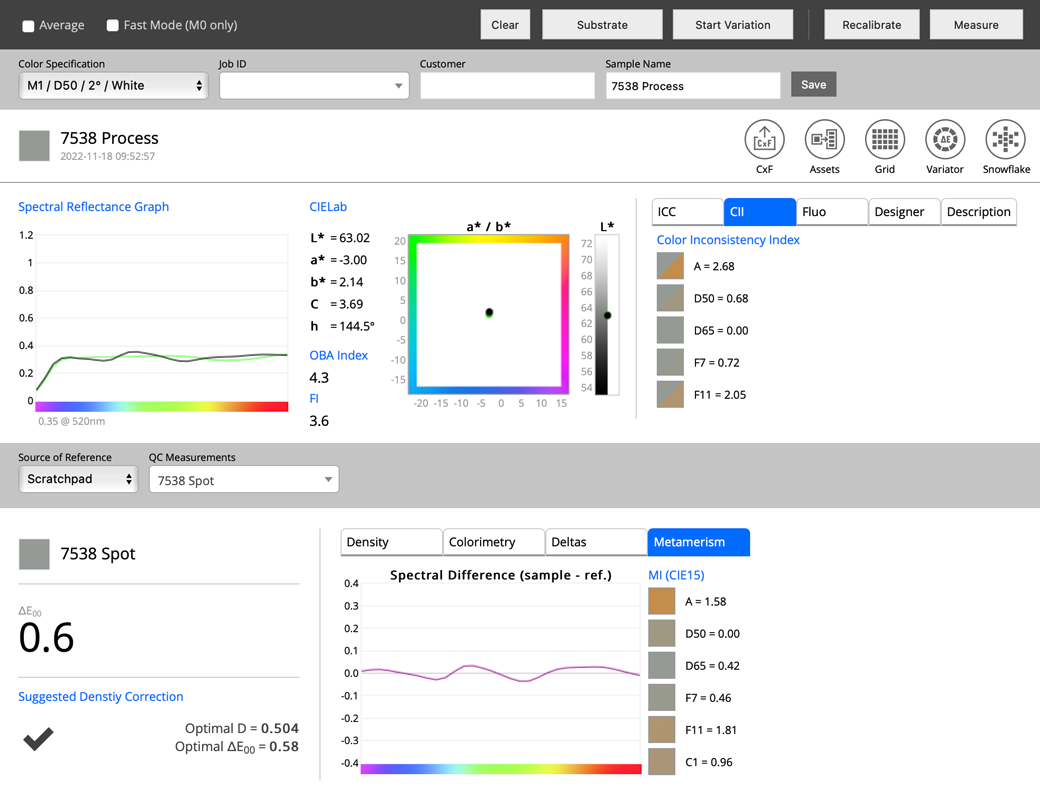

2. Measure the sample on the right side (of the Pantone Bridge book).

Name it - in this example: "7538 Process."

Now we can see different values of CII

A=2.68 and F11=2.5.

3. Set a Reference for the Sample.

Go to "Source of the reference" and select Scratchpad. Select from the list the recently created: "Spot 7538."

Now Capture displays the difference between the two colors ∆E 00 = 0.6 — but that is when we compare colors under D50/2°. The Metamerism tab shows that differences for different lighting conditions are much larger.

A=1.58, and F11=1.81

The Spectral Difference graph shows which spectral wavelengths impact the metamerism phenomena.

Conclusion

Suppose any printed product is made from multiple colors and substrates that have to match under different lighting conditions. In that case, it is critical to predict the effect of different lighting on those samples before you start production.

- Standard D50 - used in the Print Industry, is not the same as what we have in department stores where products are exposed...

- Controlling Lighting Condition is an important component of an advanced approach to color. Custom lighting conditions can be implemented in the workflow if you can measure them.

- Anticipating metamerism is critical. A practical tool like CC Capture makes this evaluation fast and simple to understand.

- Ink formulation has to be adopted to specific requirements - it is possible when spectral color reference is created. When ordering Ink, you may specify MI

- Select proper Color Specification that is a combination of Illuminant, Observer, Measurement Conditions, and more... (backing, aperture, geometry...)

- Create standards spectrally and create realistic tolerances as a key part of the standard. Color difference can be specified using different formulas, where ∆E2000 is only one of them.

In-depth case analysis.

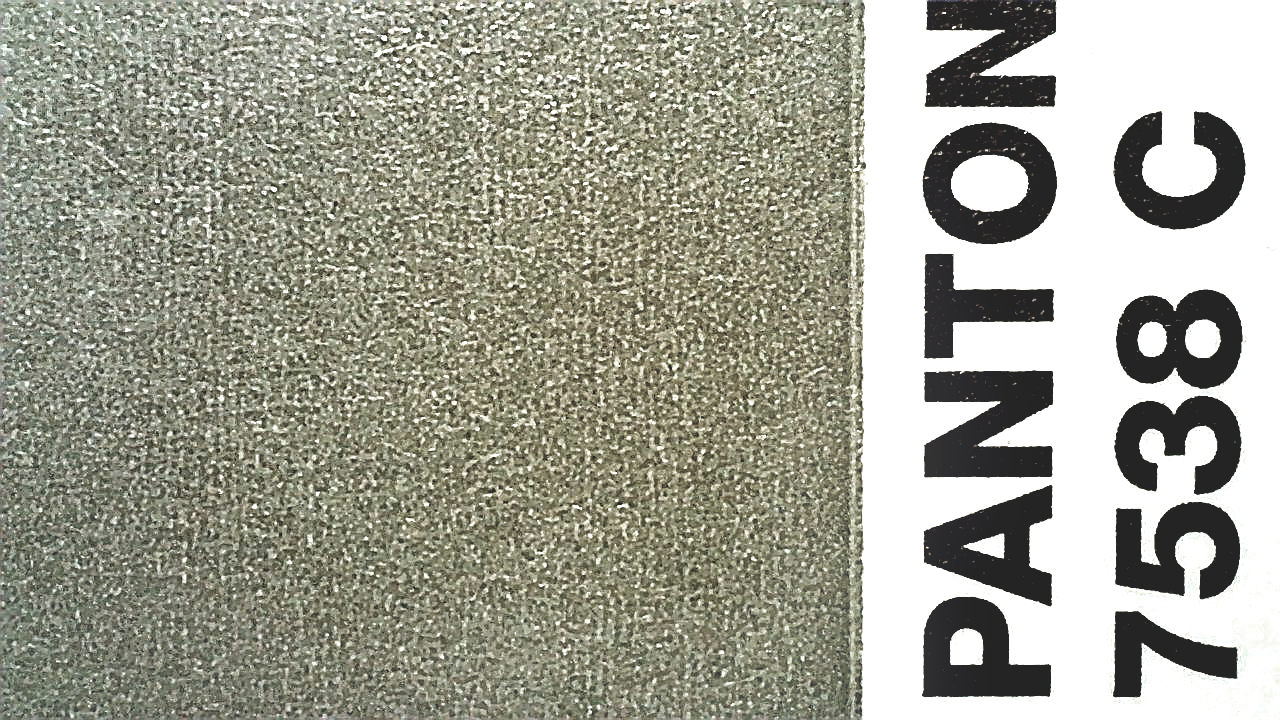

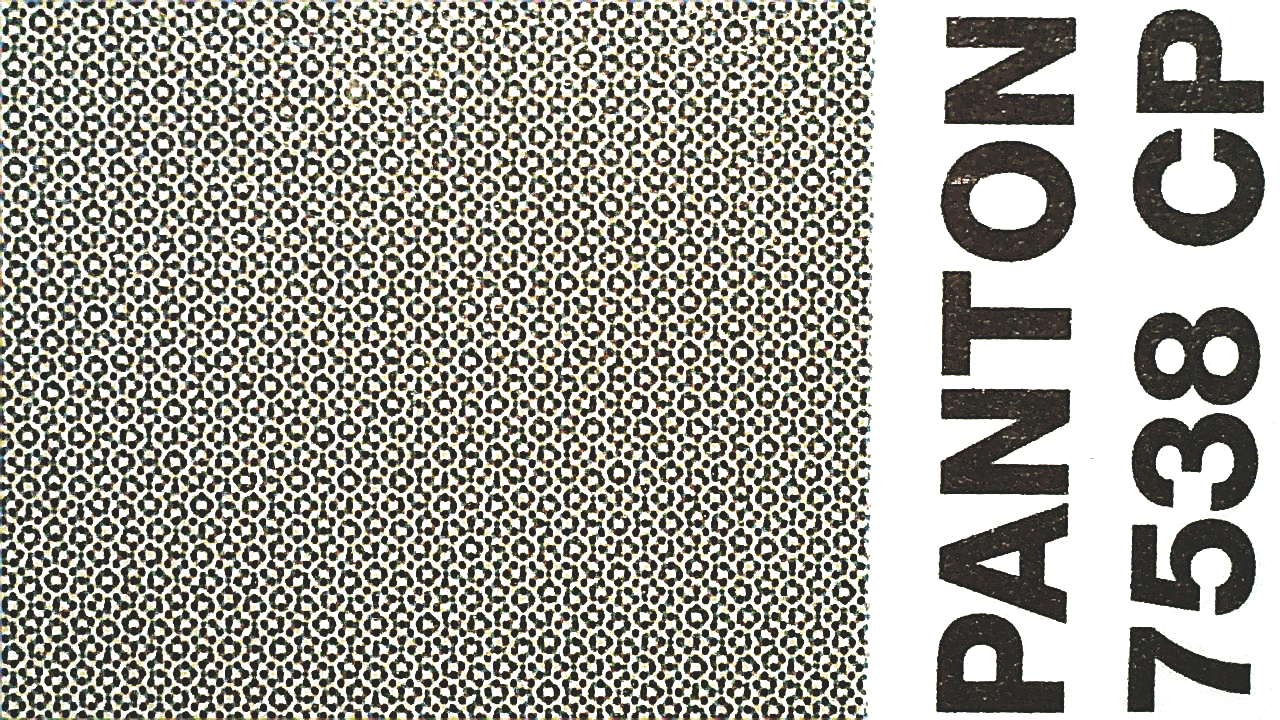

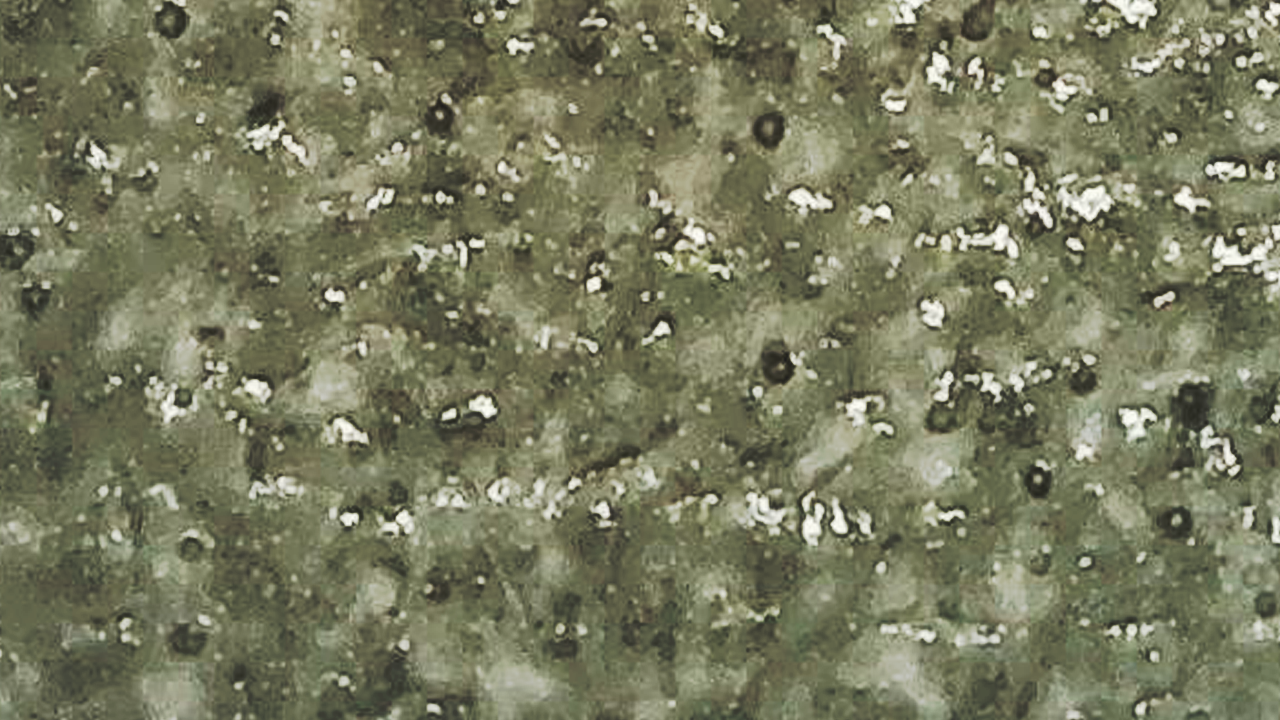

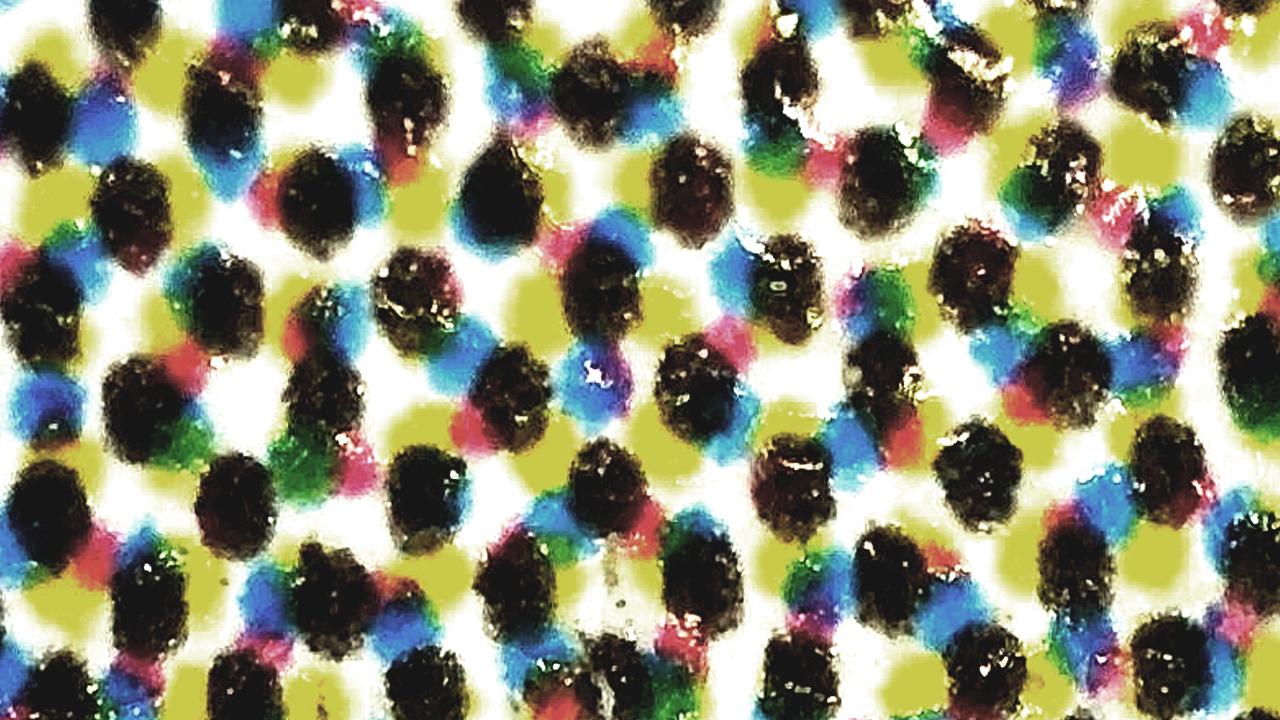

Let's examine the samples closer... with a microscope (real photos).

| Spot (Reference) |

Process (Sample) |

||

|

|

||

|

|

||

| All surface is covered with ink, but on close-up, we can see that the paper is not flat and the ink is not distributed perfectly. That proves that even solid printing is not very simple, and many variables can affect the final product's color. |

We can see unprinted areas of the paper - which cause a slightly higher OBA Index of 4.4 (while 3.9 for the reference). This printing process is sensitive to dot gain and slurring doubling issues. Stable reproduction might be more challenging. |

||

| 100% solid ink Note that most ink can be formulated in many different ways based on different colorants - and it changes the final spectral curve - when ordering ink, it can be adapted to precisely defined spectral specifications. Also, by replacing a transparent component of the ink formula with white, it is possible to control the opacity of the ink and control OBA's influence on the final color. |

Raster of: 24% Cyan, 11% Magenta, 24% Yellow, and 33% Black |

More about MI (Metamerism Index) in CC Capture.

- There are a couple of formulas that are used for quantifying Metamerism. ChromaChecker uses CIE 15 specification with a fixed ∆E 2000 formula for the final result. Lab data are CIE-corrected. This formula is very different from e.g. HunterLab MI.

- To set up a different observer or illuminant - a new Color Specification has to be created. Custom Lighting and other parameters related to CII and MI calculations are defined in Color Inspector Global preferences.

- The formula is NOT symmetrical - results depend on that is the reference and which is a sample; switching them changes the result.

Related pages:

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.