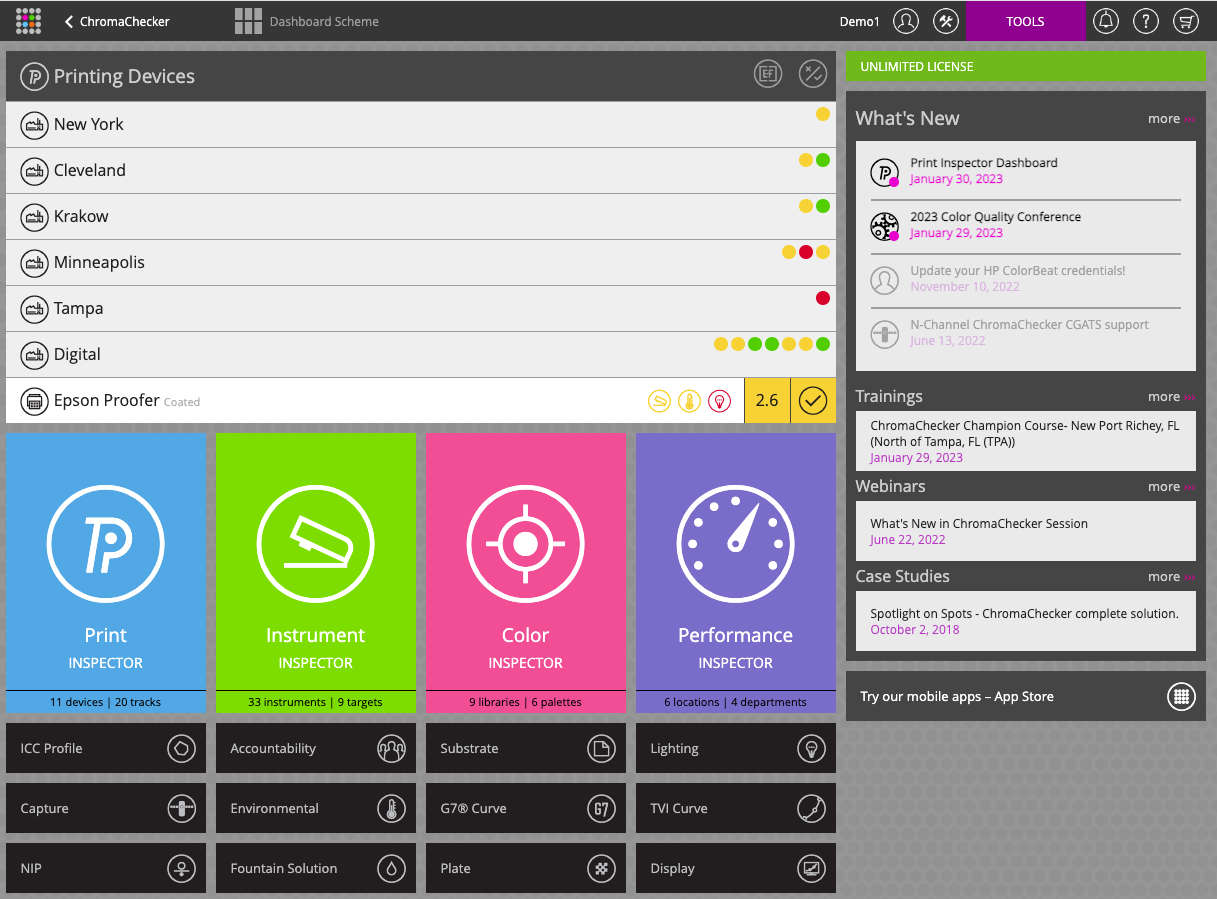

Reporting

Zero-waste Reports — from Top Management to the Operators.

Reporting is one of the key ChromaChecker benefits to the organization. While many other color measurement programs provide the reporting to one person, ChromaChecker can create custom reports for every top manager, middle manager, and operator reporting to them on the print devices that they are responsible for.

Any company wanting to migrate to lean manufacturing entails implementing continuous improvement programs for the employees, which require consistent feedback on how each employee performs against the company's lean manufacturing goals. ChromaChecker Report provides weekly reports to every individual responsible for print manufacturing. It provides new perspectives to the employees, helping them understand the big picture and their role in improving the company's performance.

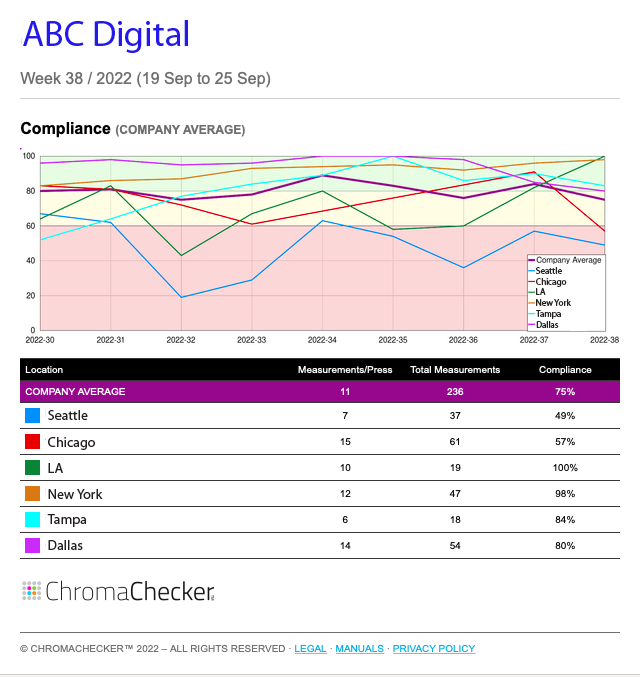

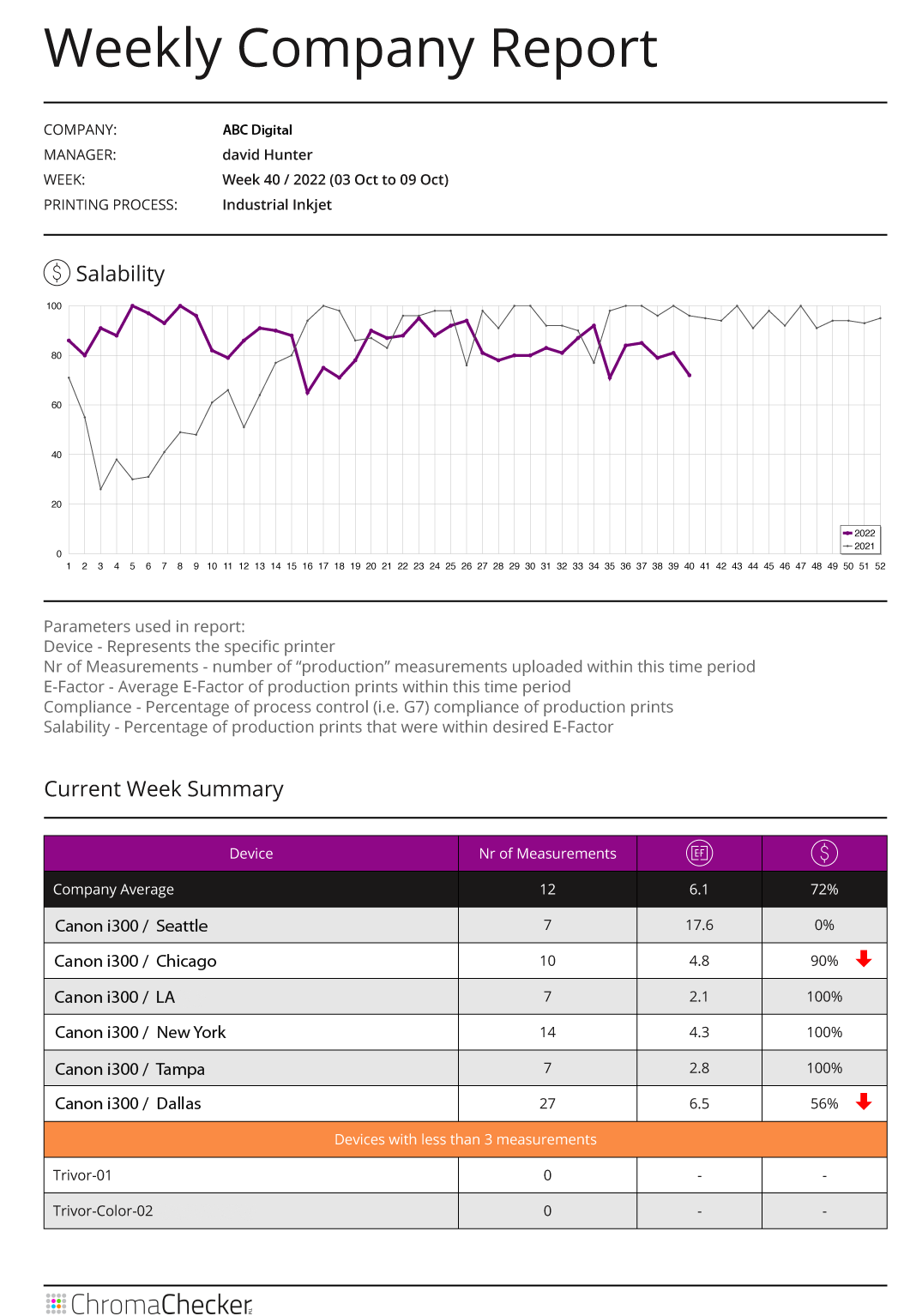

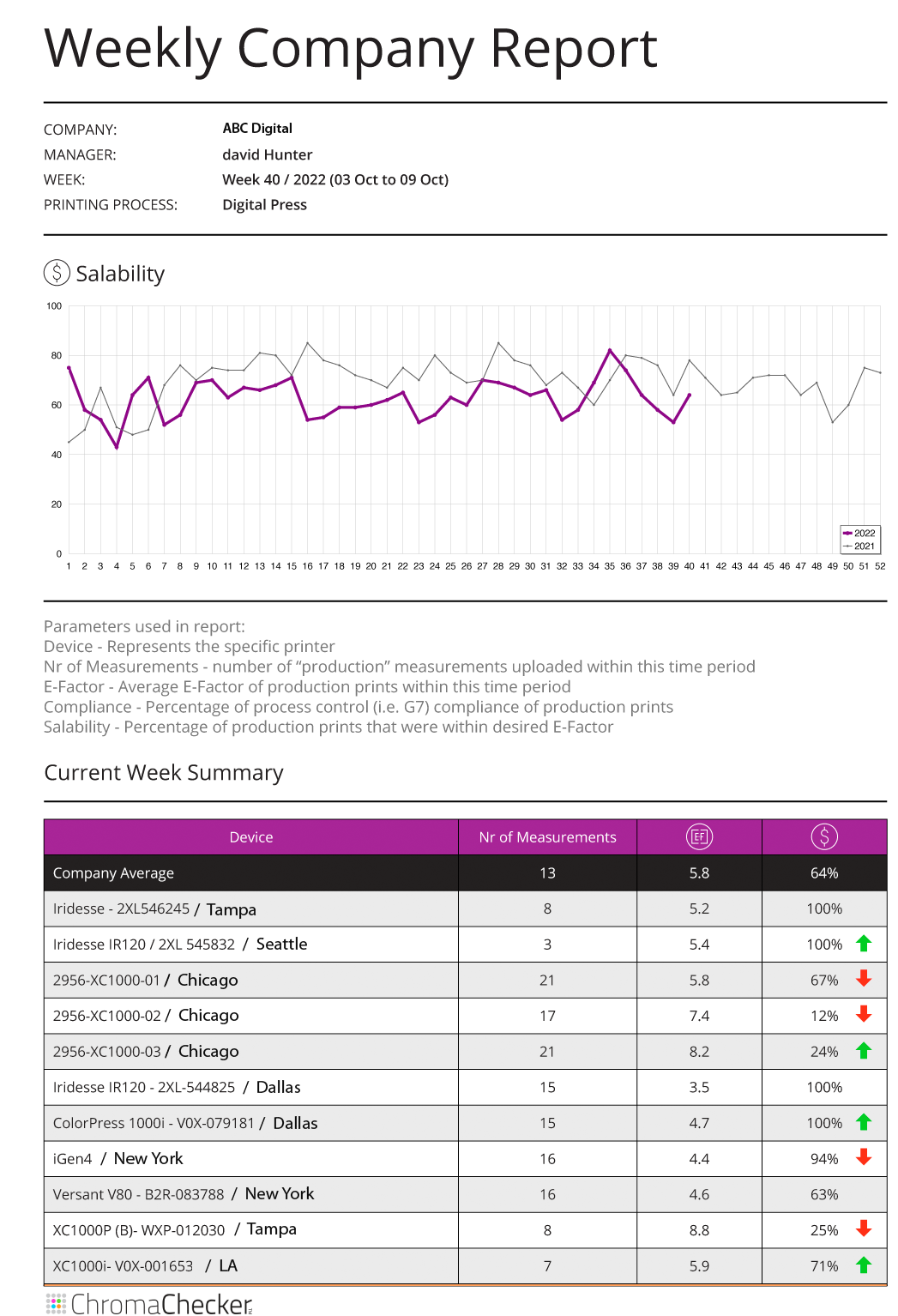

Department Report — all digital presses in all locations.

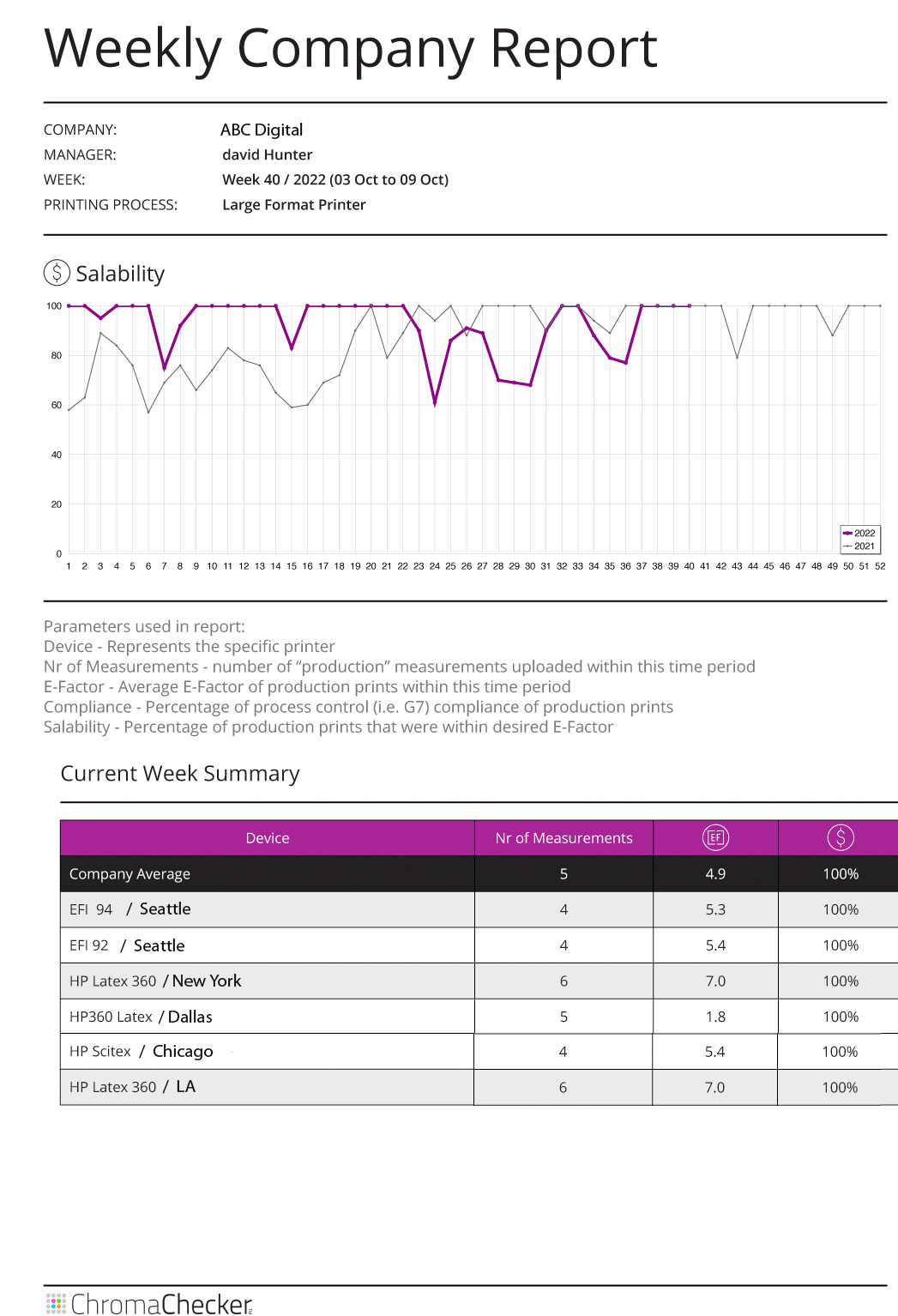

The ability for management to get weekly reports informing them on how well each production device is performing is invaluable in communicating if each device is making money or losing money. If a device is not performing well, a deep look at the data can determine if the problem is operator-specific (potential training opportunity) or printer-specific (manufacturer maintenance) to get the device back in a profitable condition.

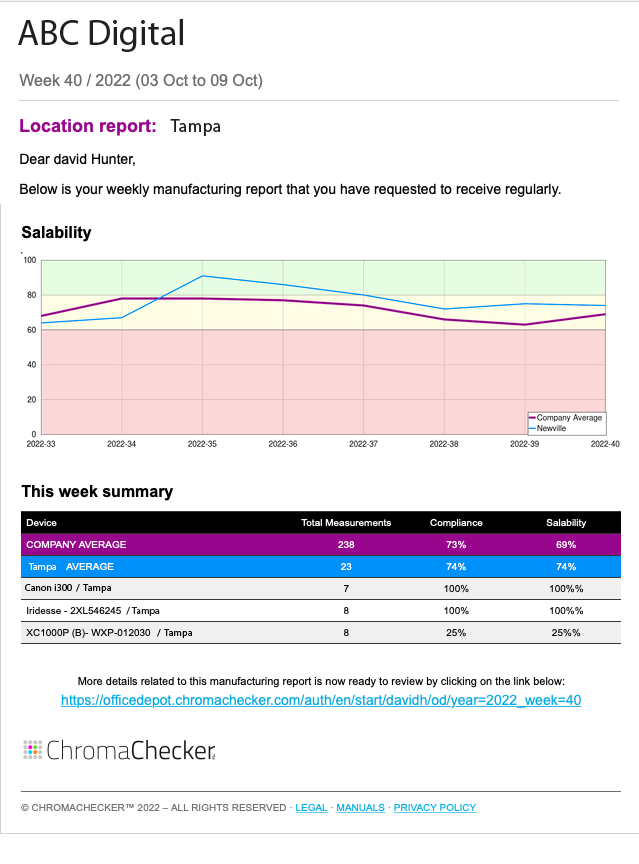

Notice that the plant manager only sees how their facility performs compared to the company average. They do not see the details of the other facilities. Also, notice how the report stack ranks the printer's performance from good to bad against the plant average, allowing them to focus on the worst printers and improve their performance to bring up the plant average.

Business and management locations are unimportant since the data is uploaded to the ChromaChecker cloud. All responsible parties have direct access to how any printer under their responsibility performs at any time.

|

|

|

Notice this report shows how each printing device performed over the last week. If a printer started failing conformance, it could be addressed as quickly as possible to improve the facility's performance.

Even though ChromaChecker creates real-time reports for the operators for every measurement, sometimes operators do not pay enough attention to the report in order to fix the printer should the report state the device is failing conformance.

This report can show how the operator performed against other operators in the organization of like devices. This helps operators see how they are performing in the organization as a whole and helps them understand if they need to get more training and improve their performance to help the company.

Video

-

For Print Buyers and Printers today reporting on color quality is a critical part of communication. This tutorial shows how to create a Job Report using ChromaChecker's job reporting functionality. This is designed for both Print Buyers and Printers to best communicate color conformance and define processes that increase productivity.

-

Whether you are a manufacturer in Plastics, Fabrics, or Print you need to get color satisfaction for your customers. ChromaChecker delivers the complete platform and applications required for accurate color reproduction: lighting, instrumentation, substrates, and actual devices.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.