Instrument Geometry, What You Need to Know

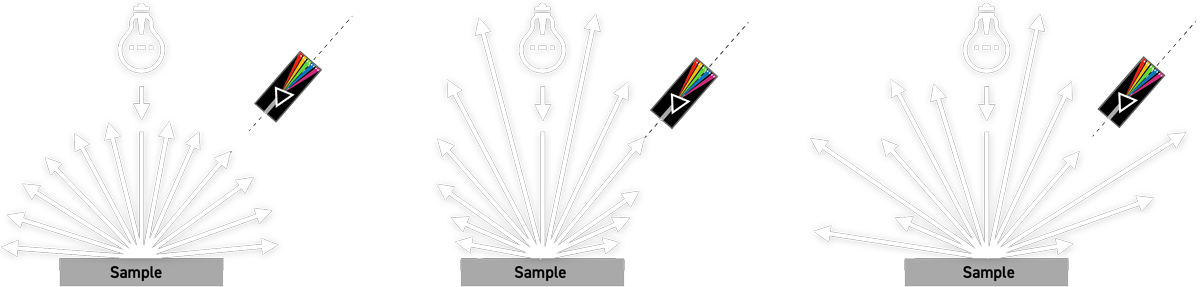

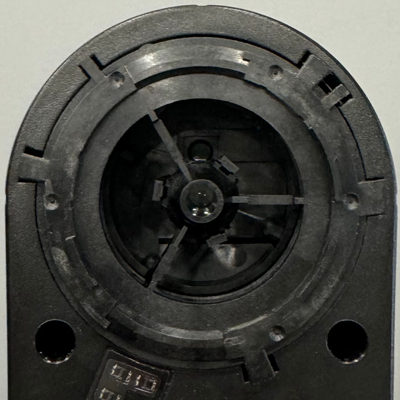

Certain types of materials cannot be effectively measured with certain types of measurement devices because of the geometry that the instrument uses to measure the color. We will review a simple test that anybody can repeat to understand the difference between how a spherical Instrument (CC Sphere in our test) and a 45°/0˚ Instrument (i1Pro3) measures printed color (CC224 target) on a foil (mirrored) substrate.

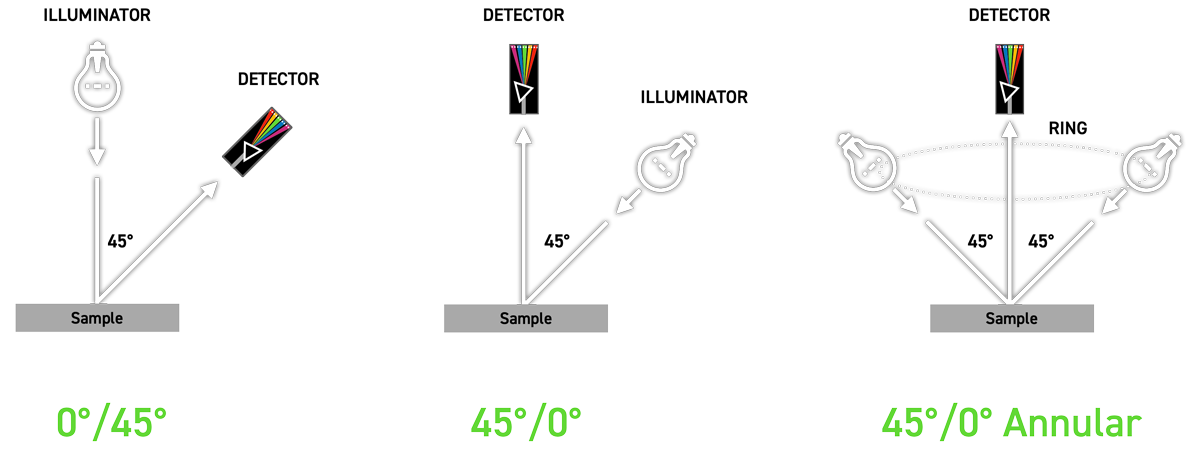

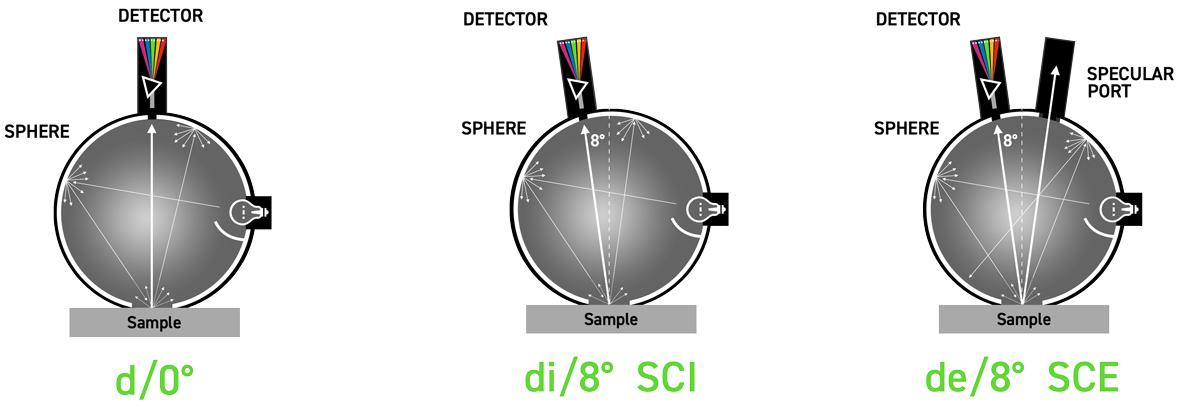

Measurement Geometry is standardized. If you are not familiar with this topic please read a dedicated document before.

The following diagrams taken from it help to understand the content of this article.

The primary goal is to determine the best methodology to control the printing process on this material. Our customer is doing a lot of production using this substrate.

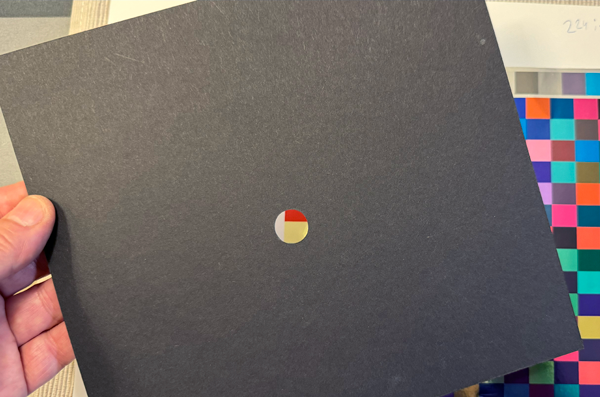

To provide a visual representation of how the different instruments measure this substrate, we have created a simulation for our eyes to demonstrate how the different instruments react to this print on a foil substrate. You can do the same thing, just take a white and a black piece of paper, glue them together, and cut out a small circle hole (approximately .5 x.5 inches, about the size of a color patch of the CC224 target (shown below). Next, we will observe the CC224 target on foil by looking through the hole of our black/white paper elevating the paper a few inches from the printed foil target. We will switch the black/white paper side back and forth and document the difference in the appearance to our eye.

The selected foil works like a low-quality mirror. Most of the light from the instrument is reflected according to the principle that the angle of incidence is equal to the reflection angle. Because of this, when we look straight into the mirror, we see our own reflection. In this case, the material is not a perfect mirror, but we can still recognize the outlines of the reflected image.

Test 1 — without instrument.

Props used in the experiment:

1. CMYK (CC224 target) printed on foil material.

2. Sheet of paper with one black and one white side and a hole in the center.

|

|

| Black side | White side. |

Results:

| Looking through a hole with the black side facing your eye. |

Looking through a hole with the the white side facing your eye. |

|

|

| Almost all samples besides light blue reflect the white side of the paper - all colors are saturated and correspond to our expectations. We can see on light blue patch reflection of the hole where the camera is inserted. The camera looks like a black object. | When the black side is facing the foil, it reflects the black surface of the paper. Some samples - due to the ink layer that is covering the foil absorb light and behave partially like a matt finish reducing the mirror effect. |

Test #2 — Measure a couple of foil samples with different instruments.

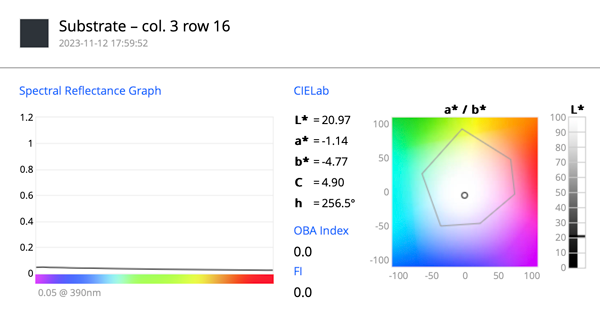

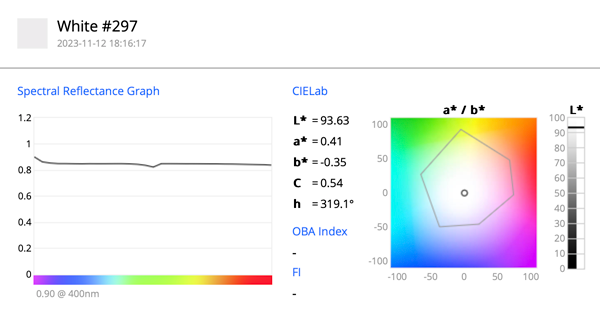

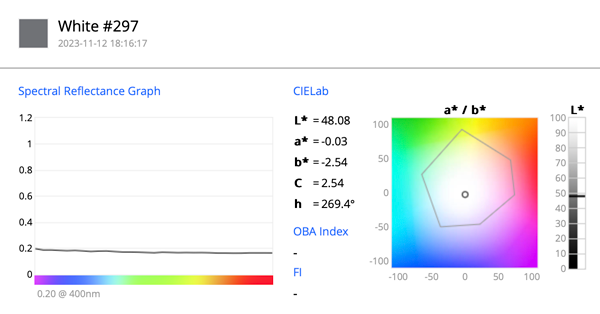

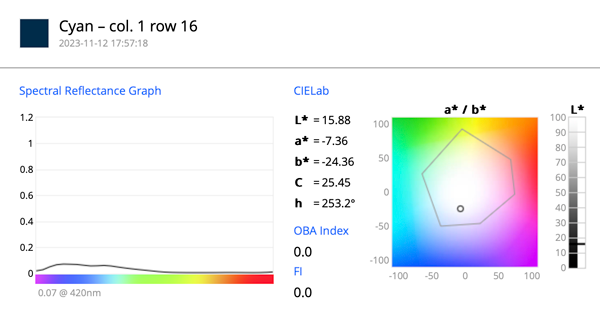

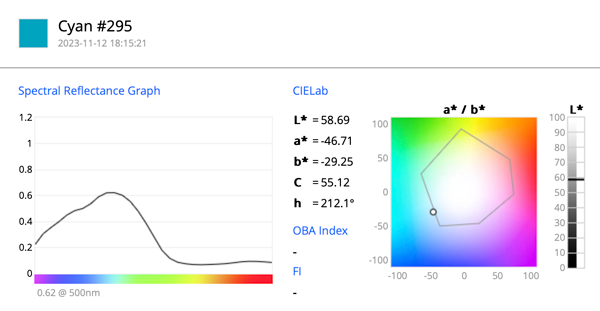

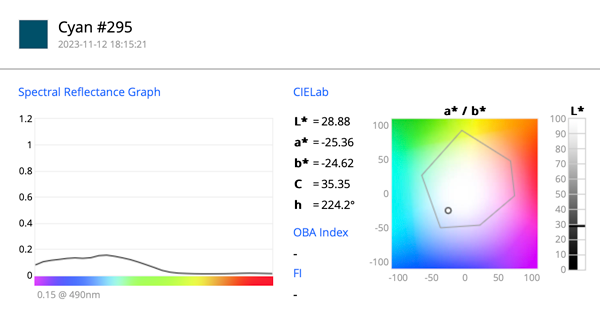

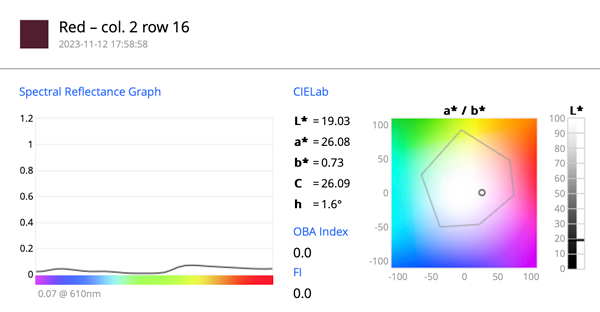

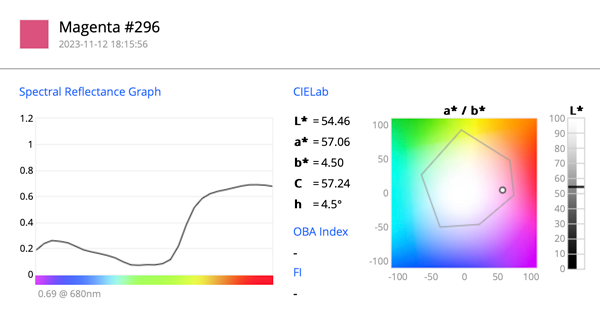

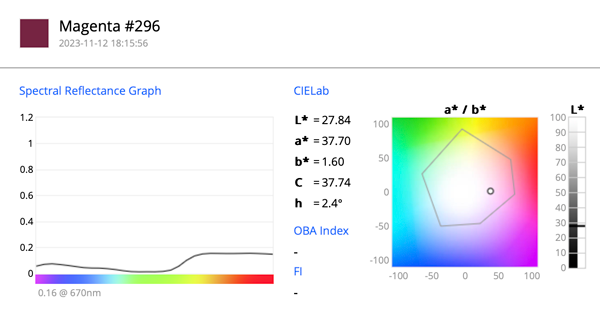

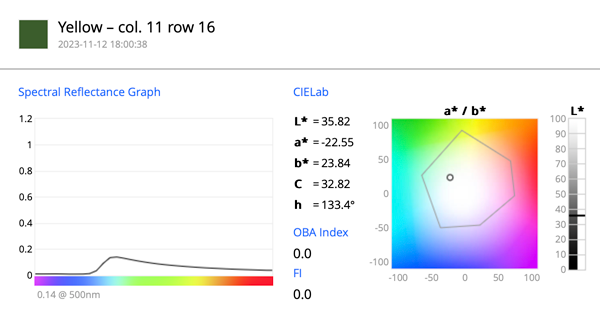

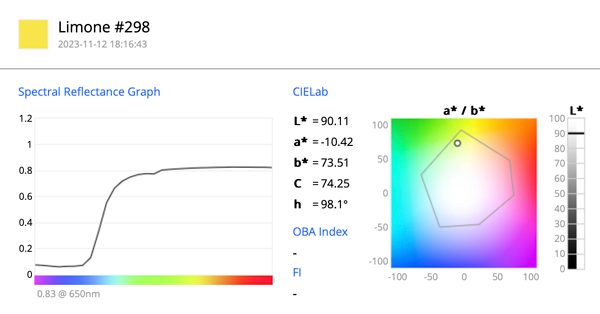

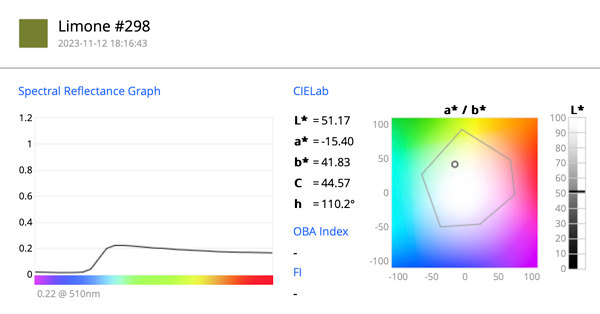

We have selected 4 color patches to compare measured results using different instrument settings.

| X-Rite i1Pro 3 | CC Sphere SPIN | CC Spere SPEX | |

| Substrate (16/3) |

|

|

|

| Cyan (16/1) |

|

|

|

| Magenta (16/2) |

|

|

|

| Yellow (16/11) |

|

|

|

Conclusions.

- I1Pro3 works well with paper-type substrates but fails to properly measure foil, metallic, and other materials with mirrored reflection properties.

|

A perfect annular ring is not visible at the right angle - all that is mirrored by the metallic surface is black. This is equal to the scenario when the black side of the paper faces the sample. |  |

|

| Please note that i1Pro 3 sees the Yellow sample (L=35.8) much lighter than the Substrate (L=20.9) - that is because the annular ring causes an enlightening sample, which is due to the printing process being layered with the ink, resulting in less gloss. Some portion of 45-degree light made it lighter. | |||

- If we need to implement process control for this material, the SPIN data works great and corresponds with human perception.

- When comparing SPIN and SPEX data we see that difference is related to the glossiness of the object. For a perfect matt surface SPIN=SPEX

- Whenever you measure high gloss samples such as metallic, pearlescence, or similar textured effects a spherical instrument may be the only reliable solution.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.