|

|

ChromaChecker – 5 steps to Color Conformance

|

1. Standard |

2. Baseline |

3. Adjust |

4. Track |

5. Integrate |

|

|

|

|

|

Color Conformance Platform |

|

|

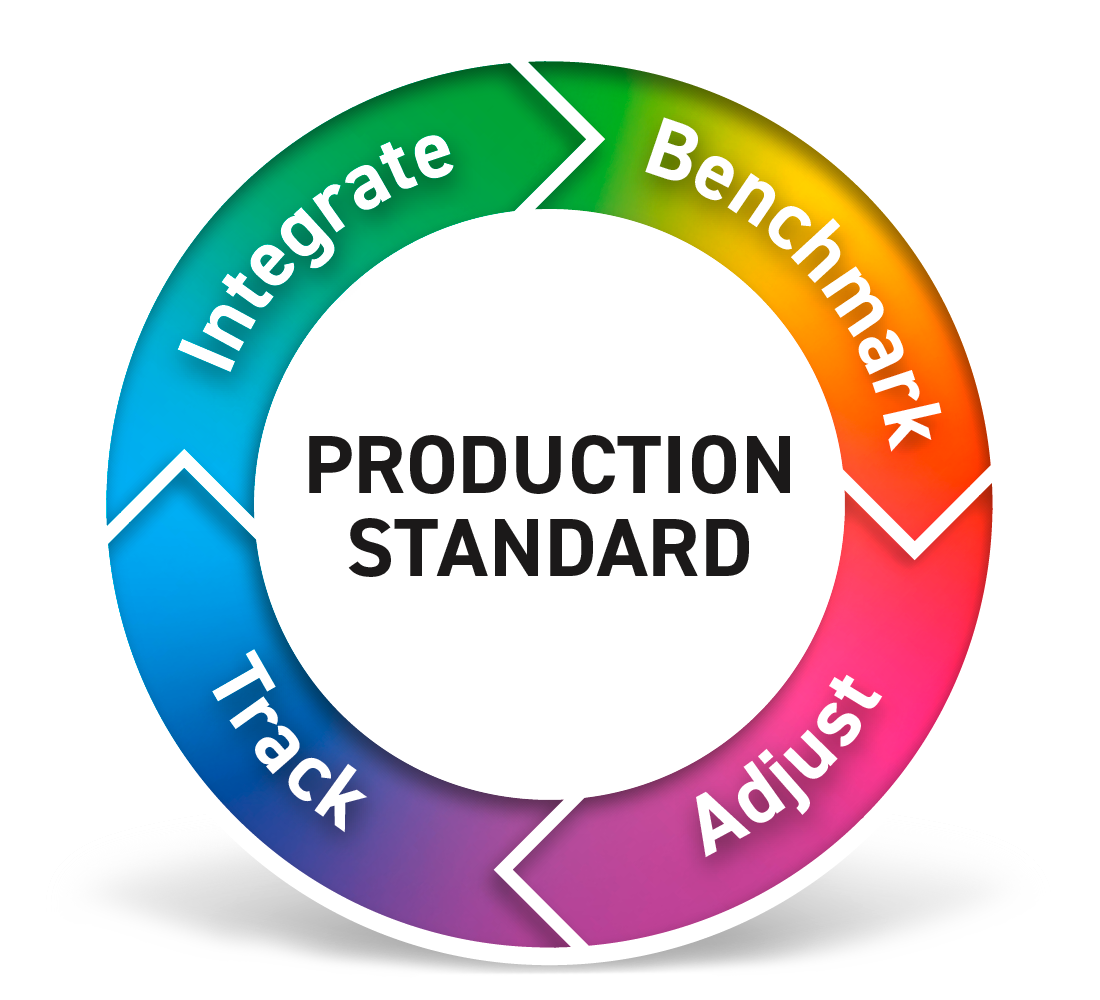

ChromaChecker centralizes all color communication and empowers Print Manufacturing. This platform is unmatched by adopting industry standards to achieve predictable, consistent, and accurate results; monitoring process, and eliminates waste which improves companies profitability in today's market. |

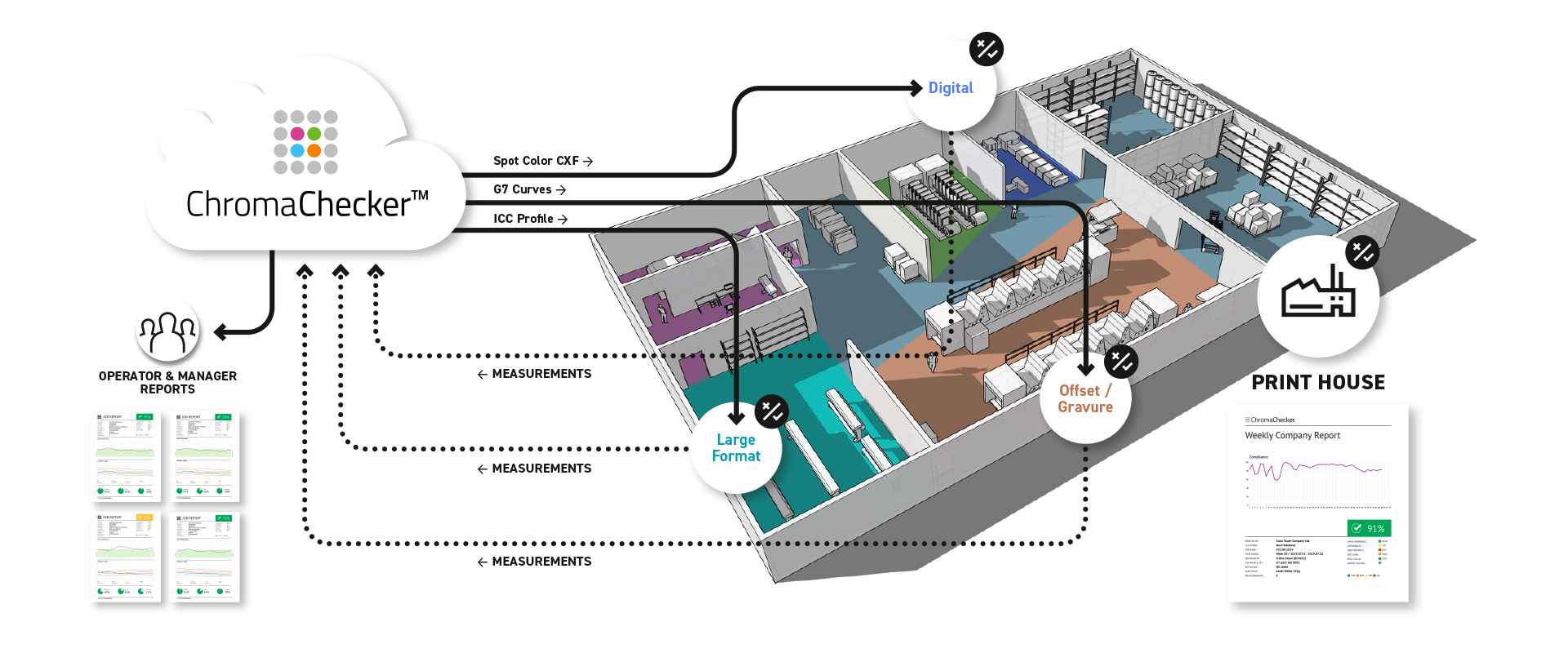

Assessing print to a Production Standard using Pass/Fail criteria directs operators and management to keep the press running when it's within expectations and stop the press if the output is failing. Using a number based visual expectations allows the organization to ensure jobs are salable. |

|

|

Provides print operator with Production Standard pass or fail

Easy for operators to know if Job is salable

ChromaChecker serves production by providing tools to quickly pinpoint errors and generate G7 curves and ICC profiles to fix accuracy between substrates and align devices. It also centralizing libraries for substrate, instrument performance, spot color libraries, lighting, and displays. In addition, ChromaChecker provides custom targets allowing for the tightest and flexible tolerances possible. Chromachecker is the most advanced platform for manufacturing jobs that are color critical.

Control of the conformity of production between printing devices/production departments

|

![]()

Centralized Color Platform that ingests color data and exports reports and analysis which includes:

- color variation and deviation

- creating press calibration curves - (TVI or G7 Inspectors)

- creating ICC Profiles

- process-control

- performance and salability

Supplemental tools provide a more accurate picture of the production process.

- Plate Inspector - traces plates production

- Lighting Inspector helps to keep standardized lighting on press consoles and QC departments

- Environmental Inspector is monitoring RHT parameters

- NIP Inspector documents NIPs

- Accountability Inspector grants access to the system for operators and managers

- Performance Inspector helps to create a birds eye view of the entire Organization

Can your curve software do this?

CC Capture |

ChromaChecker |

Curve |

ColorCert |

PressSign | |

|

Predicted Best Match to hit brand colors quickly, and process solids |

– | ||||

|

Create Grid to find closest color match |

– | – | – | ||

|

Preview print or on screen all color variations for different delta E's |

– | – | – | ||

|

Print and preview Snowflake showing color differences in independent Lab axis |

– | – | – | ||

|

Create and Iterate G7 Curves |

– | – | |||

|

Create G7 Curves with single row using Exact, and 3 row target for i1 |

– | – | – | – | |

|

Create Projects for Customer Brands |

– | – | |||

|

Assess Process Color Compliance based on Visual E-Factor metric |

– | – | – | – | |

|

Check Lighting to ensure lighting is aligned between viewing stations |

– | – | – | – | |

|

Create ICC Profiles for Print and Display |

– | – | – | – | |

|

Automatic weekly reports sent to managers and operators of printers for continuous improvement reporting |

– | – | – | – | |

|

Job reporting for customer showing how jobs printed accross every printing device any where in world |

– | – | |||

|

Accomodate that no two measurement devices measure the same, and allow different quality stations to compare to same physical standard |

– | – | – | – | |

|

Tracks how printing device and or operator performed over any time period |

– | – | – | ||

|

$549.00 / One Year |

$1,190.00 / One Year |

|

![]()