High Pressure Indicator

Nip Pressure Indicator measures the plate to blanket pressure and the impression cylinder to blanket pressure in each unit of the press. Ideally, the cylinder pressures should be as low as possible to produce good ink transfer still. The units should be consistent with one another to allow for different inks to be moved between units. Today, most units are found to be greatly overpressed (too much excess pressure) and inconsistent with one another. Using the Pressure Indicator, the operator can baseline the units to a common, low-pressure value which not only saves electricity but saves tremendous wear and tear on the press and provides for consistent imaging with all inks in all units. The Nip inspector will track the cylinder pressures over time, and the ChromaChecker Accountability Inspector defines reminders to the responsible operators to ensure the press is maintained properly.

Auditing Plate to Blanket and Blanket to Impression pressures

to determine the course of action.

The Nip Pressure Indicator is used to measure the Plate to Blanket pressure within each unit, and the pressure values can be entered into ChromaChecker via the iPad app to document the condition of the pressures in each unit. The pressures are critically important since they directly affect dot gain (TVI) within each unit of the press. The pressure for all units should be documented before any Plate Curves are built or ICC Profile targets printed. Ideally, the NIP pressure values must be documented to establish a “repeatable baseline” to return to in the future. The plate curves will only work for the pressure conditions of the cylinders when the plate curve targets are imaged on the press. The cylinder pressures should be set with minimum pressure and consistent with one another before a baseline is established. Measure all the cylinders and enter all values in ChromaChecker Nip Inspector, and then ChromaChecker will show the within-unit consistency and between-unit consistency to ensure all the units are consistent with one another.

Why estimate blanket height when interested in pressure?

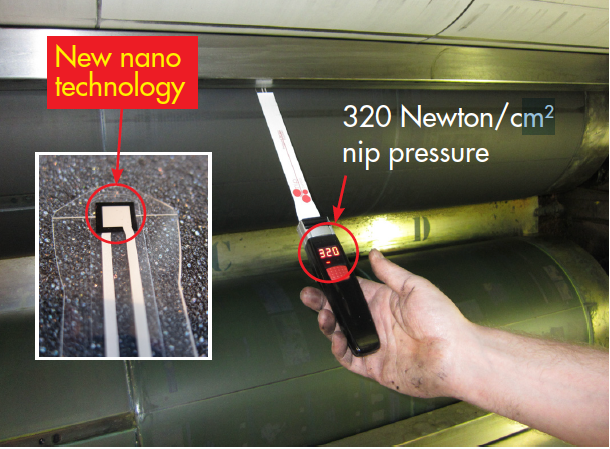

Optimal transfer of the ink-water emulsion from plate to blanket and, finally, to paper is fundamental to superior and stable print quality. Now, for the first time, rapid measurement of nip pressure between cylinders is possible – thanks to the innovative Pressure Indicator – High-Pressure version!

Nip Control’s Pressure Indicator makes it easy to monitor nip pressure changes over time or determine how pressure changes with different underpackings, blanket compressibility, and more. The Pressure Indicator can help decide whether a printing problem can be attributed to pressure variation in a cylinder nip.

|

||

|

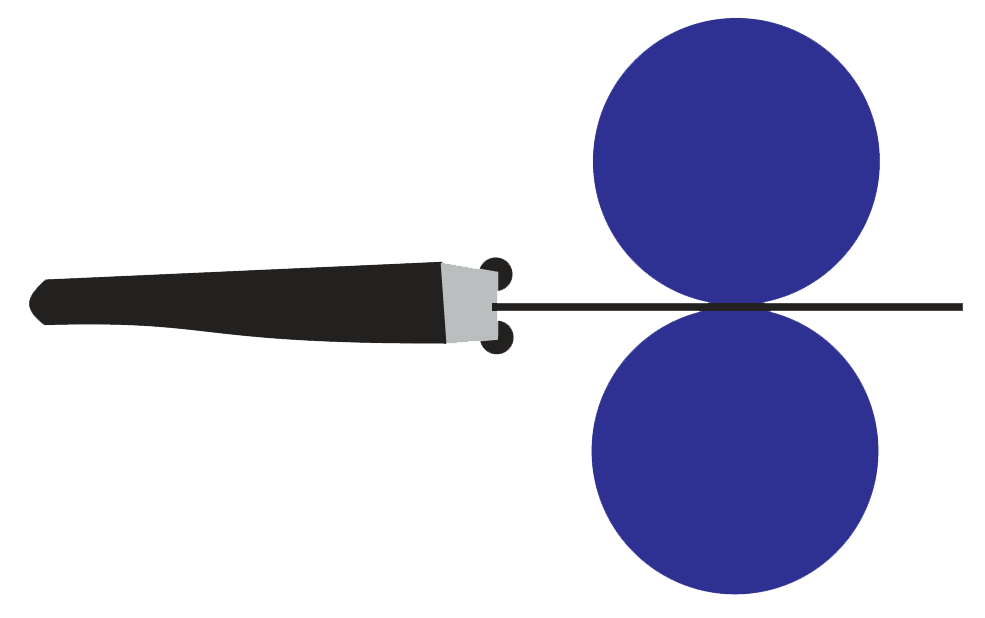

Simple to use Allow the cylinders to draw the tip of the thin sensor blade through the nip to provide an instant nip pressure value on the display. |

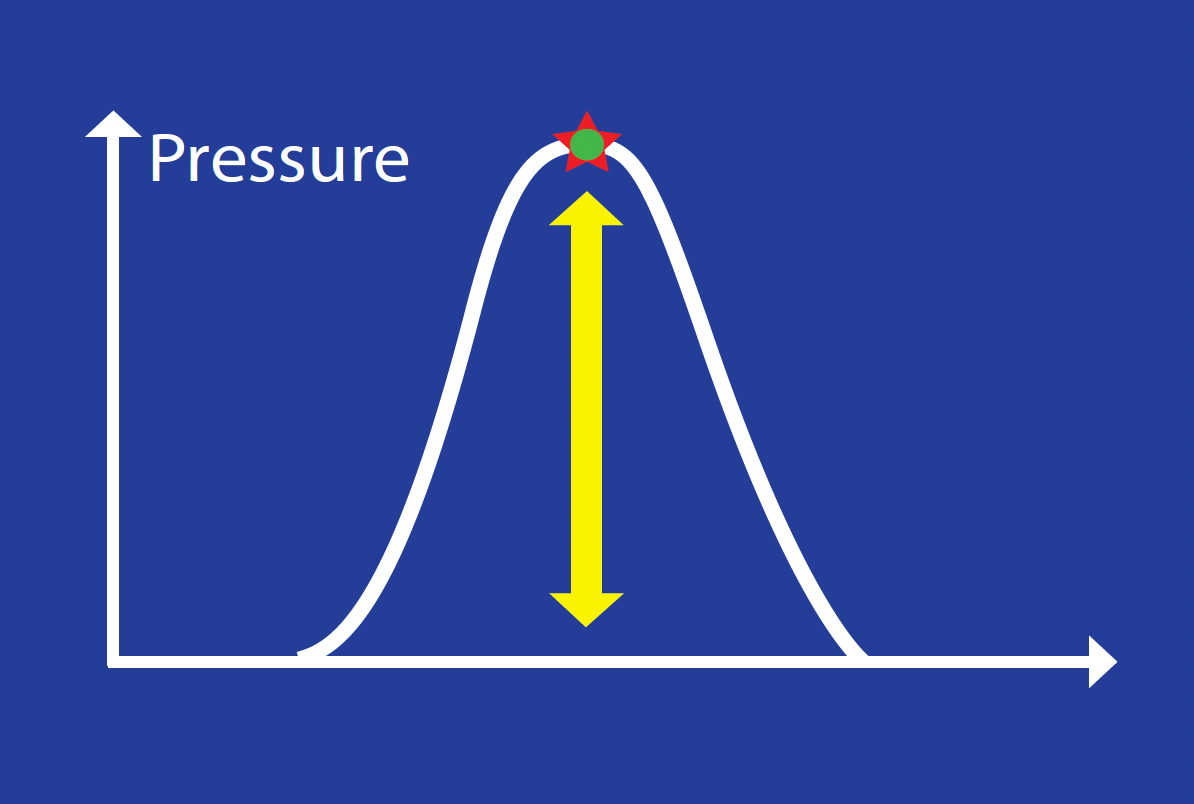

Peak Value

|

All nips generate a pressure curve. The Pressure Indicator monitors the pressure increase as the tip of the sensor blade moves through the cylinder nip (Rolling Nip™). The instrument then displays the peak pressure value. The peak pressure is what transfers the halftone dot from the plate to the blanket and – eventually – to the paper! A mounted offset blanket is commonly monitored by measuring the blanket's height in millimeters or inches. Compared to the precision of the Pressure Indicator, however, this is something of a ”trial and error” approach to estimating the pressure level between plate and blanket, blanket and impression, or blanket to blanket cylinders. |

Simple calibration

|

Just insert the pressure-sensitive tip of the sensor blade into a calibration tool. Press the control button — and calibration is complete! Watch the video attached to see how easy it is. |

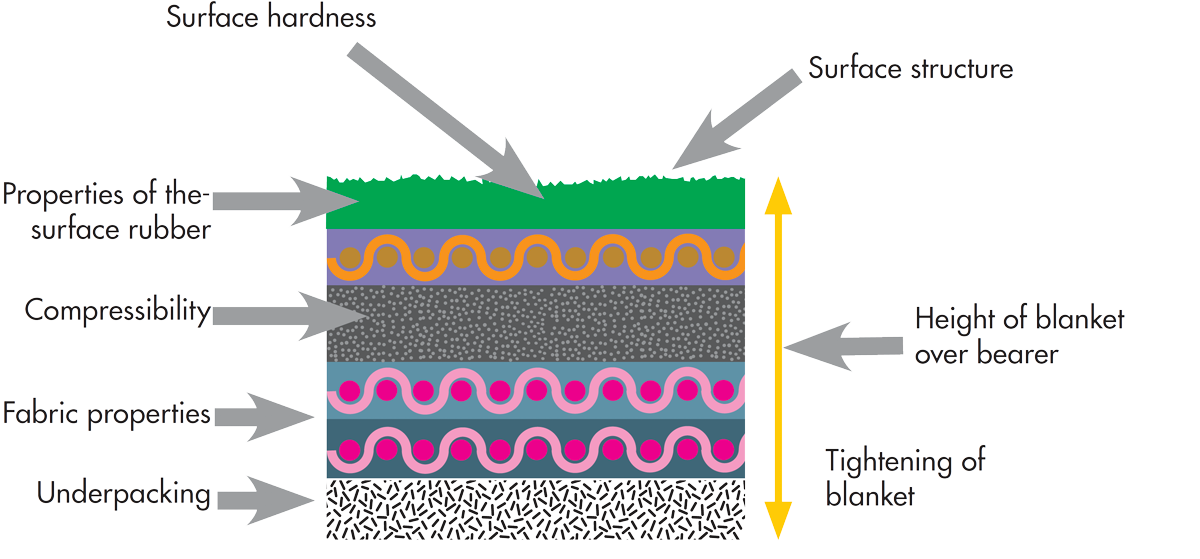

Blanket properties affecting nip pressure

|

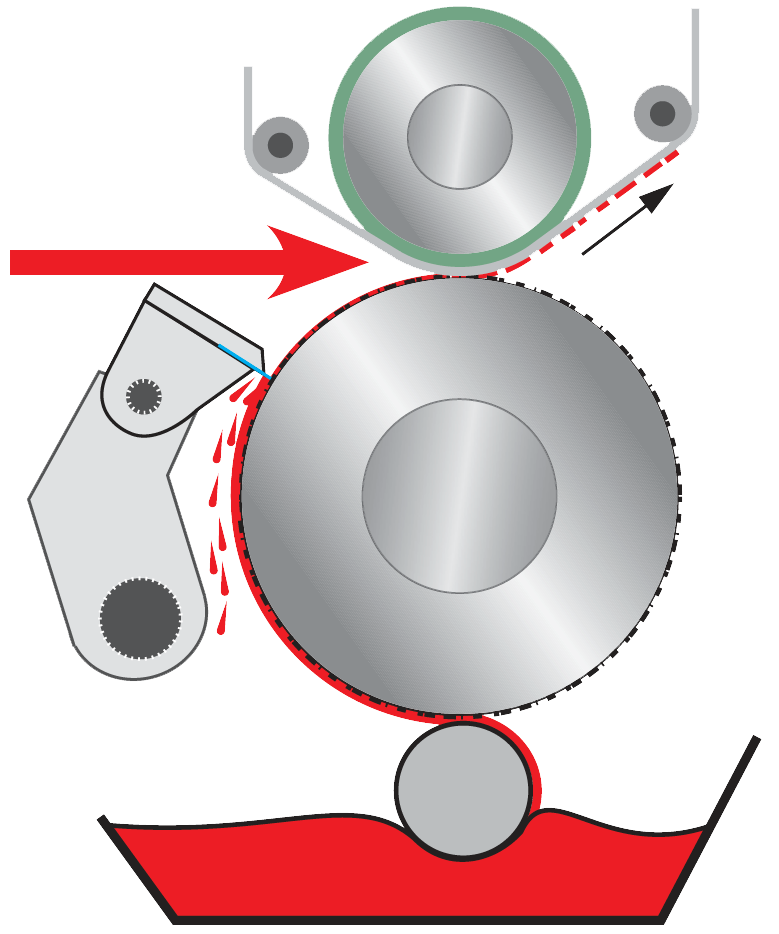

The illustration shows the multiple blanket properties that combine to determine nip pressure. Blanket properties will vary over time. For example, the compressibility layer will “sink” through usage, reducing nip pressure. At the same time, the surface rubber hardens, producing an increase in nip pressure. Uniquely, the Pressure Indicator – High-Pressure version provides a true reading of nip pressure that accounts for any variations in blanket properties at the precise moment of measurement. |

Rotogravure

|

In gravure presses, the measuring is performed between the impression roll and the gravure cylinder. |

||

|

“We have learned much about nips in different gravure presses and how to standardize.” Mr. Kobayashi Atsuchi |

|||

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.