NiP Control's Width Indicator

Nip Width Indicator (NWI) is designed to measure the Ink Roller Stripe for each unit digitally and allows the operator to immediately adjust the roller while the NWI is in the ink roller nip to get the stripe to the correct value. This “digital measurement of the stripe” should be done at least once a week to ensure the ink rollers are set correctly. The ChromaChecker accountability inspector provides the ability to associate a responsible operator(s) for every device (including the Nips for the press) and define when periodic measurements have to be taken to ensure the Nips are consistent. The Accountability inspector will send email notifications to ensure this process is completed on a timely basis and alerts if the device fails or goes beyond the defined time period ensuring the Nip Ink Roller stripes are maintained in a consistent manner.

How the Nip Width Indicator measures Ink Stripe: Record values in ChromaChecker Nip Inspector

The NIP width indicator tool allows press operators to digitally measure the ink roller stripes for each press unit. Instead of “eye-balling what 4mm stripe is, the operator can digitally set the ink rollers on the fly to a “measured” 4 mm strip. The values can then be entered into ChromaChecker color cloud via the web browser Operator interface or CC Capture to document that the Nip widths have been checked within the defined time frame.

Precise, Fast, and Clean nip width measurements

|

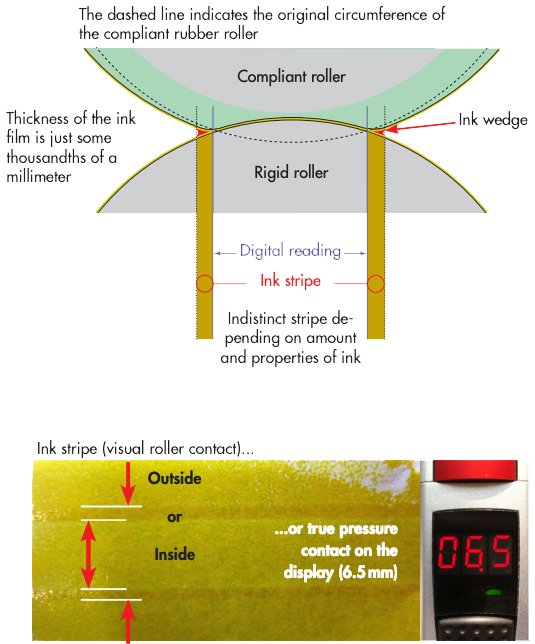

The roller nip is critical in offset printing, both transporting and processing the ink and fountain solution. Offset technology is unique in that its process components – ink and water – are mixed under pressure. The ink stripe – indicating the visual imprint when two rollers are in contact – varies according to type and amount of ink as well as in terms of viscosity, tack, and yield value. Analyzing an ink stripe is not always easy or accurate, due to its indistinct edge. Pressmen sometimes estimate from the outside of the stripe, sometimes from the inside. The Nip Width Indicator employs a different approach, measuring the nip width from the moment actual nip pressure is applied until it ceases. Maintaining a true, process-correct nip width at a constant level ensures the greater stability of the overall offset process. The Nip Width Indicator – a high-technology digital instrument – measures nip width based on the true roller pressure contact. |

Measure - how to procedure

- Position the tip of the sensor blade between the rollers

- The display shows readings in millimeters or inches

- Adjust the nip width to the desired level

Measurements should be taken at both ends of the roller nip and in the center. Measurement and roller settings will always be the same – whoever performs the task. No ink is needed, so no cleaning is necessary after measurements are completed. However, if you need to troubleshoot while in production mode, measurements can be taken even with ink on the rollers.

Easy to Use

- One-button control

- Only one operator needed

- Bright LED display for easy readings

- Standard AAA batteries and power-save function

- Sensor blades can measure with either side towards either roller

- Three-step safety design to protect the operator

- Can be used on all offset presses from any manufacturer

- Delivered in a robust instrument case

Digital nip width measurements - benefits

Improved Productivity & Print Stability

- Measures nip width where true roller pressure starts and stops

- Correct measurement regardless of ink type and ink viscosity

- More precise than visual ink-stripe estimates

- Detect uneven nip width due to swelling, shrinking, or non-parallel alignment

- Up to 50 percent quicker than estimating an ink stripe

- Pressman-independent. Objective and standardized. Facilitates printing by numbers

- Digital measuring stabilizes the offset process

- Correctly adjusted roller nips ensure process variables – ink and water – are optimally transported and mechanically processed

- Better controlled process results in more production time

- Fast and easy troubleshooting

- A cleaner measuring technique: no ink or cleaning agent

Note:

The roller load and corresponding ink stripe is calculated by the press manufacturer for new rollers. Nevertheless, the rubber’s characteristics change over time. The surface hardens and sometimes swells or shrinks from the effects of ink and chemicals, temperature, bulk elasticity, and a number of revolutions. Consequently, an initially correct nip setting can become incorrect, leading to instability and deterioration of the offset process.

Traceability option

Please note that this is a hardware option. The user can't upgrade later. Be careful when ordering.

Traceable Calibration™ – the ultimate quality control feature The standard Nip Width Indicator instrument self-checks the sensor blade during start-up. If the sensing element has become worn from usage and no longer meets specified performance parameters, a message will be displayed, warning that the blade cannot be used. Many companies, however, follow quality standards which include measurement traceability. Nip Control’s new calibration and verification system for the Nip Width Indicator fulfills these demands.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.