Print Manufacturing

Color Conformance Platform

ChromaChecker by centralizing communication empowers Print Manufacturing. When it comes to color this platform is unmatched by adopting industry standards to achieve predictable, consistent results; monitoring process controls, and eliminating waste making companies competitive in today's print market.

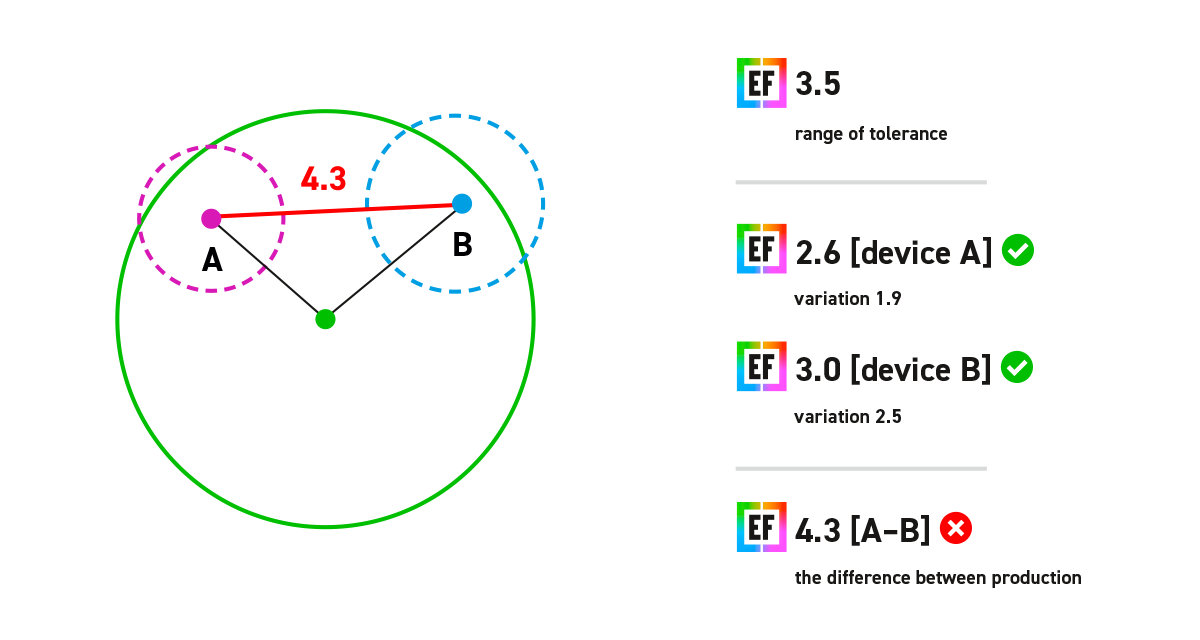

Providing a Pass/Fail result directs the operators and management to keep the press running when it's within tolerance and stop the press if the output is failing required expectations. Using a number based on DeltaE or E-Factor, the organization is alerted when something affecting the color quality chain is not inappropriate specification including Instrumentation, Press Condition, Materials, Lighting, and Environment.

- Quantify customer’s “color match” expectations upfront

- Establish printer’s color quality capabilities

- Know when “color match” production is sellable

- Meets customer’s expectations the first time, every time

Provides Output Operator Single Number Conformance

Easy for Operators to know if Job is Salable

ChromaChecker serves the needs of production by providing tools to pinpoint errors and generate iterated G7 curves and ICC profiles to fix accuracy between substrates and align devices. It also services the needs of the Brand & Print Buyer by providing reporting that defines the shift in color while centralizing libraries for substrate, spot color definitions, lighting, and monitor. In addition, for the highest quality requirements, ChromaChecker provides custom targets allowing for the tightest and flexible tolerances possible. Chromachecker is the most advanced platform for communicating color that is designed for production.

Control of the conformity of production between printing devices/production departments

|

![]()

A unique eco-system — production color measurements are used for multi-purpose analysis

- color variation and deviation

- creating press calibration curves - (TVI or G7 Inspectors)

- creating ICC Profiles

- process-control

- performance and sellability

A lot of supplemental tools give a more accurate picture of the production process.

- Plate Inspector - traces plates production

- Lighting Inspector helps to keep standardized lighting on press consoles and QC departments

- Environmental Inspector is monitoring RHT parameters

- NIP INspector documents NIPs

- Accountability Inspector grants access to the system for operators and managers

- Performance Inspector helps to create a bird-view of the entire Organisation

![]()

Related Topics

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.