T42 / i1iO lifetime test

This test shows how multiple scans and scratches made during the contact i1iO measurement affect the readings of the T-42.

We performed this test by limiting the consumption of the target only to the frictional effects by performing one-by-one scanning of a new, previously unused target T42 so that our users could learn without unnecessary scratching the effects of the contact measurement method and draw conclusions to extend the service life.

Test Conditions

- I1Io version 2 was used in the test.

- The instrument has been adjusted to reduce pressure while maintaining contact across the entire surface.

- The gliding ring is more than a year old, and is not in a perfect state!

- The Baseline is created from the first 5 measurements (default CC Capture value for i1iO)

- The new, never used before T42 target was measured 57 times. (5 + 52 = a year of verifications on weekly basis)

Visual judgment

What is important is that the scratches on the surface were visible after a few measurements, but they can only be seen at a certain angle when looking against the light. In the top view, they are practically invisible. The transparent foil used reduces the effect of scratches on the color change, but the surface, through micro-scratches, changes the matt surface to slightly scratched. You can also see quite clearly how the instrument is moved over the entire surface during the entire measurement process.

Two pictures of the same T42 measured 30 times, taken from two different viewing angles.

Numbers!

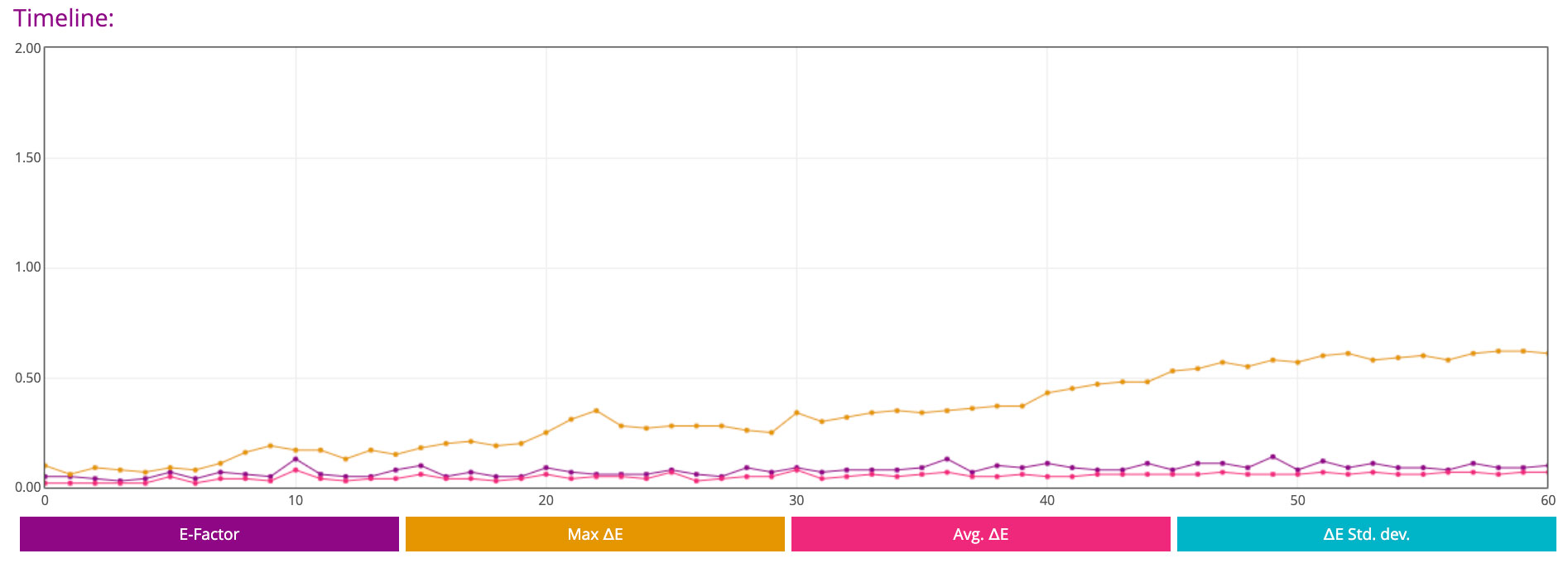

Let's see a timeline!

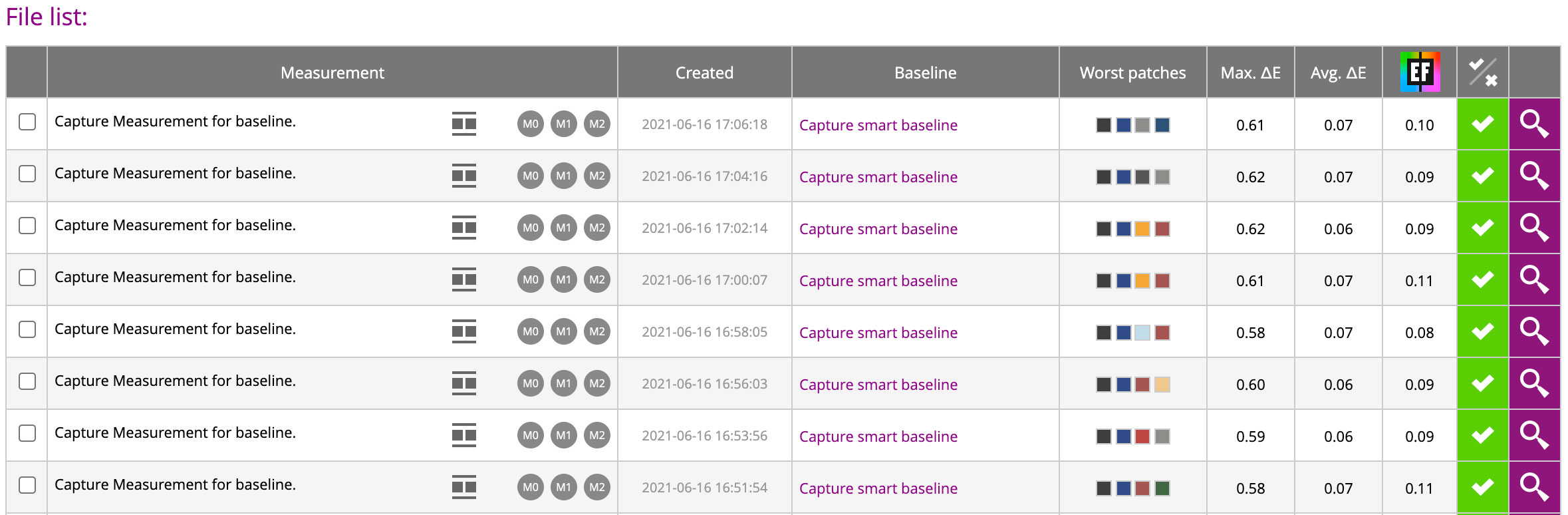

and last few measurements data:

We can see that E-factor is pretty low (violet line /0.10), while at the same time the max. ∆E is rather high (yellow line/ 0,61). Going deeper into expert mode we can observe that only one patch has a problem. It is not hard to guess that it is a black one - the most sensitive on changing appearance when glossiness is modified.

Let's continue! Not 50+ but 200+ measurements.

The test was launched as a loop task. During scanning, scratches caused by the worn-out glitter ring caused the formation of a thin layer of white dust on the surface of the target. This affected the measurements, which were stopped for a moment and the T42 was wiped with a clean microfiber cloth (the relevant event is marked with a vertical line on the timeline) to check the effect after a few scans, the wipe was repeated, this time with a moist microfiber.

You can see how strongly the results are influenced by the removal of dust from the surface. The cleaning was repeated once more - each time improving the readings.

Conclusion

A perfect glitter ring and lifted arm are keys to extend the T42 lifetime. Why? To understand take a close-up look at the ring.

If your glitter ring is in a similar condition you should replace it with a new one. This part has a limited lifetime and can be ordered from the vendor.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.