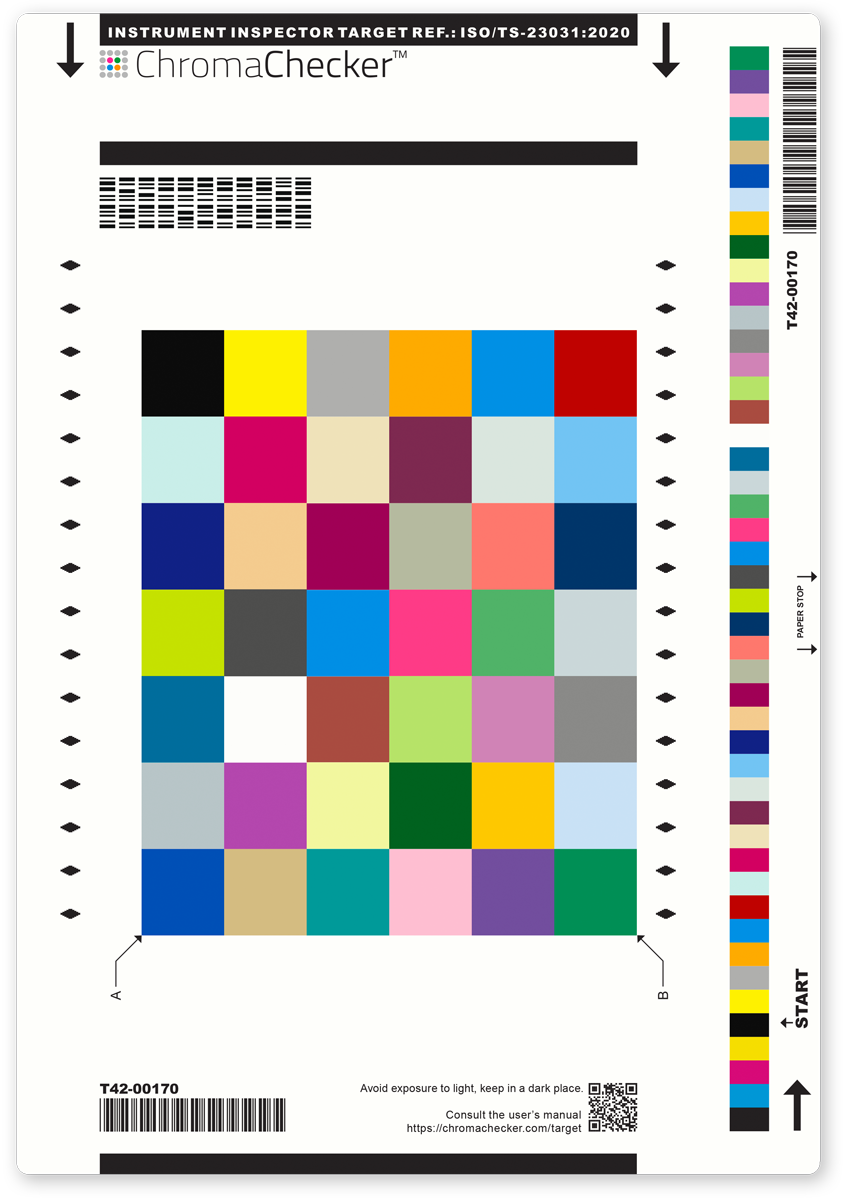

T-42 — Instrument Inspector Target

- 42 patches with spectral improvements

- Design and technological improvements

- Matt finish GU

- Patch Size: basic layout (6x7): 21x22 mm, single-line layout (I-42): 6x10 mm

- Printed on the substrate w. OBAs

- Integrated I-42

- iSis barcode with serial number embedded

- Selfbacking (Opacity >99%)

- Thickness 0.41 mm

- Rounded corners

Complementary Sets

There is no printing process that does not have variance. Neither the printing substrate nor the printing technology itself guarantees perfectly accurate repeatability. ChromaChecker applies extreme conditions of the production regime. Each product is individually measured and compared with the others. Color consistency within one product and compliance with the production baseline are analyzed. Each color sample has at least 6 comparative pairs. The entire production series is compared to each product with each other. The result of very advanced analysis is the isolation of complementary sets with a controlled individual difference. It is not possible to print two absolutely identical products - but it is possible thanks to our internal analytical system to select products so as to minimize the differences.

- Production variations E-Factor < 0.2

- Patch difference in a single complementary set Max. <0.3 ∆E2000

The difference between targets that are not a part of the complementary set might be >1∆E.

Note:

if you need two or more targets that will be similar to each other in a controllable way - order the targets in a complementary set.

Patch uniformity

A single measurement of a portion of the measurement field may differ depending on the location. Therefore, accuracy is based on taking not one but many measurements and averaging them. The size of the measurement field also has a significant impact on the accuracy of measurements. Especially in scanning mode, the number of samples is related to the speed of travel and the length of the field. Therefore, the T42 currently has very large measurement fields and the scanning algorithms multiply the number of points measured for averaging. Baseline generation involves multiple measurements and each repeated measurement within a single patch All of these principles together determine the accuracy of an evaluation.

Take care and keep your target clean.

Measurement fields are protected with a special foil. Its purpose is to protect the target against damage and dirt. It should be remembered that any interference on the surface will change the instrument readings. Touching your fingers allows sweat particles to enter the surface - and this alters the reading. The surface is resistant to water and many chemicals - however, minimal changes in reading affect the color. Your precision requirements must correspond to the attention to precision in your measurements.

We recommend the following cleaning methods:

1. Dry cleaning with a microfiber cloth

2. Wet cleaning with a water-moistened microfiber cloth (requires 20 minutes to get dry)

3. Wet cleaning with a microfiber cloth dampened with soapy water. Requires additional cleaning with water only, and dry.

It is possible to use acetone to clean stains not removable with soapy water - but only in case when Target is contaminated with inks or so. Acetone cleaning will change baseline readings and a new baseline will be required. THat will lose records continuity - and breaks the ability to auto-certification for ISO 9000 purpose.

Aging and fading resistance.

We make every effort to select all components taking into account the requirements of maximum durability of our targets. In order not to use technologies different from production conditions, a certain level of sensitivity to fading and aging remains always. Caring for the target will help increase its durability.

Note:

A few rules will allow you to achieve stability over time:

- After use, protect the target against light by placing it in black factory packaging.

- Avoid touching with your fingers

- Avoid contact with chemical agents

- Avoid extreme temperatures

- Make sure that your instrument does not damage the mechanically scanned surface - eliminate the cause before permanently scratching the target.

Important note

Most of the instruments are measured by contact methods. This results in the formation of scratches and mechanical damage to the target. By applying the recommendations, you can significantly reduce mechanical damage and extend the life of the target. Typically, instruments have to read the printout once, in which case the same target is to be scanned dozens if not hundreds of times. The only strict application of the recommendations will help keep the target in good shape.

Please select and read guidelines related to the instruments that you are going to use

| CC Capture | 3rd Party |

| X-Rite eXact | Intellitrax |

| X-Rite i1 Pro 1, 2, 3 | Barbieri LFP |

| X-Rite i1iO 1, 2, 3 | Konica-Minolta FD-9 |

| X-Rite i1 iSis 1,2 | Virtual Colorimeter |

| Techkon Spectrodens | |

| Konica Minolta Myiro-1 |

It might be interesting to learn more about the relationship between scratches caused by contact measurement mode and reading deviations. We made a test that shows the numbers.

The precision of the evaluation - basic rules

- Don't expect scan and spot measurements to get the same result.

- Two instruments with a different design will never measure the same - it does not mean that one of them is worse, and one is better.

- Some instruments measure slightly differently when they are "cold" and differently when they make a series of measurements.

- The aperture matters - a larger one can better average the measurements

- When scanning the instrument, it also measures at the junction of two patches - algorithms can cause noticeable differences

- The scanning speed determines how many points will be measured during the shift.

- The temperature at the measuring site may have an impact on the results - make sure that the conditions are optimal

- The purity of the instrument's whiteness calibration is a key element of accuracy - always keep it clean. Likewise, the optical path must be free from contamination.

- A single measurement may not be very precise - you expect accuracy - increase the number of measurements used to average the measurement.

- Assess your requirements and adjust the methodology to your own expectations. Remember that in the real world, art is a wise compromise - fight for those parameters that benefit your production - accept the differences consciously.

If you need high precision, learn more about IGF.

Integrated I-42

We integrated the single-row I-42 control strip with the T-42 target. It should be remembered that the measuring fields of the I-42 are definitely smaller and do not give the same precision. The use of the I-42 is therefore recommended only for devices that are not able to measure the T-42. This value does not give a comparable level of averaging and, consequently, the reliability of the measurement.

Related Topics

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.