CxF: Color eXchange File format

CxF file format overview and description

This document is an attempt to educate users about the CxF/X4 (ISO17972-4) format and how it relates to spot color workflows.

If a customer specifies spot/named colors as tints, or overprints of spot colors the results are unpredictable and inconsistent between proof and press and press to press.

If a customer’s E-Factor* (CRF at the 95th percentile delta E 2000) is 6 or more, this inconsistency is probably within the customer's expectations so it has not been perceived as a problem. If the customers' E-Factor is less than 5, then CxF/X4 is a solution that will deliver predictability and consistency to spot colors, their tints, and overprints and will be well worth the time and effort to implement the CxF/X4 workflow.

To assess your E-Factor (based on CRF 95th percentile delta E 2000) visit: https://chromachecker.com/cee/en/manual, or order the hard copy exercise.

If your Expectations are less than 5 CRF at 95%, or if you have had a history of problems with spot colors and spot color tints, you will need to implement CxF/X4 for your manufacturing process. If your expectations are higher, you may want to investigate this solution more.

ISO 17972 defines methods for the use of CxF3 to exchange measurement data and associated metadata within the graphics industry.

ISO 17972

- CxF3 (ISO 17972-1) This format provides prepress digital data exchange and verification for 4 color process printing.

- CxF/X2 (ISO 17972-2) This format defines the CustomResource within the CxF/X structure for the creation of scanner target data

- CxF/X3 (ISO 17972-3) This format defines the output target data within the CxF/X structure for the creation of output printer target data

- CxF/X4 (ISO 17972-4) This format defines the exchanging spot color characterization data within the CxF/X structure

Spot colors, or “named” colors are created to provide a specific visual color for a given name on a given substrate. The process of rendering spot/named colors on different output devices is challenging due to differences related to:

- Different print technologies (colorants, screening, tonality)

- Substrates

- Ink companies and formulations

- Different tonalities on different print technologies

- Measurement devices, and conditions

- Different lighting conditions

- Overprint on white vs black vs another ink

and more…

CxF/X4 was created to solve the problem of not getting accurate/desired spot colors when printing on different devices, and not being able to accurately proof.

For years we have been able to define a spot color using a specific CIE Lab value for the solid on a generic coated substrate for a given lighting condition, but often, this was not enough to get an accurate reproduction of the color, never mind producing an accurate reproduction of the tint of that solid. When using a spot/named color library which is not in CxF/X4, then a lot of limitations come forward, including but not limited to:

- Attempting to calculate tint values by creating CMYK builds for the given color, but with no definition of what CMYK the builds are in to start with. This is a problem from the beginning.

- Attempting to calculate tint values by creating a linear regression from solid to paperwhite, which again is an estimate of what the actual tint should be, and often times will produce a hue shift that would not happen in real life.

Either of the above processes will fail when attempting to make an accurate proof or simulation of the color on a different device.

CXF/X4 was developed to help address these issues related to Spot/Named color workflows.

Implementing CxF

In order to make CxF/X4 work in your environment, you need to have the 5 C’s of Color Control.

- Color Capture device appropriate to the substrates being used in your process

- Calibrated output devices which render color consistently within the page and between pages

- Characterization of the actual spot/named colors for the given substrates being imaged (CxF/X4)

- A conversion that recognizes the CxF/X4 tags embedded in the PDF in order to convert to different print conditions (including proofing) accurately

- Conformance allows you to see the print and compare it to the Reference color to determine if it's within desired expectations of color tolerance.

1. Determine the appropriate Color Measurement device:

- Ensure measurement device is appropriate for a given substrate, a 45/0 is appropriate for measuring on paper and similar substrates where the light from the instrument is reflected at a predicted 45 degrees angle, but it is not appropriate when printing on substrates that have a metallic quality which will scatter the ancient light at different angles other than 45 degrees.

- Precision- Understand that no two instruments measure the same way and that when multiple instruments are using in a workflow, that the color conformance between them has to be calculated before implementation, or you could find yourself beyond your tolerances before you start. Use ChromaChecker Instrument inspector to ensure your instruments used for Characterization and Conformance are within acceptable tolerances based on the customers' expectations for color conformance.

2. Calibrated output devices

Obviously, for precise and accurate color reproduction, it is required to have output devices that can image color well within the customers' expectations for color tolerance. If the output device is not capable, then your company will lose money by not meeting customer expectations. By measuring color bars off of your output device and uploading to ChromaChecker allows you to ensure your output device is precise and accurate for the given printing aim.

3. Characterization

Similar to how CMYK ICC Profiling defines the characterization data set of how a given set of inks/screening/tonality/substrate/print device will render color, we need a characterization data set of how a given spot/named color will render color for a given set of inks/screening/tonality/substrate/print devices. This characterization data set is created by printing tints of the desired color over white and black ink and on a given substrate (this quantifies the opacity of the ink, which is a major variable related to color reproduction). This requires printing the required color and measuring in the result. Once we have a characterization data set, we now can predict how this named color will react when exposed to different variables such as different substrates, print devices, lighting, and mixing with other inks.

Again, similar to ICC Profiles, once you have your desired CxF/X4 characterization data for your given color, now you can provide a color palette to designers so they can more accurately see the results of this color when used in an actual design.

4. Conversion of the CxF/X4 data for different processes

Also, similar to ICC Profiles, CxF/X4 characterization data can be used to physically convert the color to different print conditions and accurately represent the original intent (assuming the output device has sufficient gamut to simulate the desired named color. This is critical for proofing the color to simulate what it will actually look like on the final device. It is also critical if the intent is to render this color on different output devices (via a Color Server) with different ink/tonality/substrates/lighting, and provide a color match to the original. Color Servers like Alwan ColorHub support CxF/X4 but will fail to produce an accurate conversion if not supplied with CxF/X4 data for spot/named colors.

This CxF/X4 data can be used in an ink formulation system to automatically generate a new ink that will share the same spectral properties for devices that can’t use the same ink that the original definition was created for. For instance, Offset versus Screen print inks.

5. Conformance to assure the printed result will meet customer expectations

Again, similar to using ICC Profiles to assess the conformance of CMYK output, the Conformance can be assured by using the CxF/X4 data as the reference and assessing if the reproduction of the desired named color matches within defined tolerances. This is where Alwan Print Verifier and ChromaChecker become invaluable in terms of showing the press operator that the print reproduction is meeting customer expectations as it comes off the press, eliminating any unnecessary waste.

CxF/X4 Characterization

For detailed description consult ISO-17972

Patch measurements:

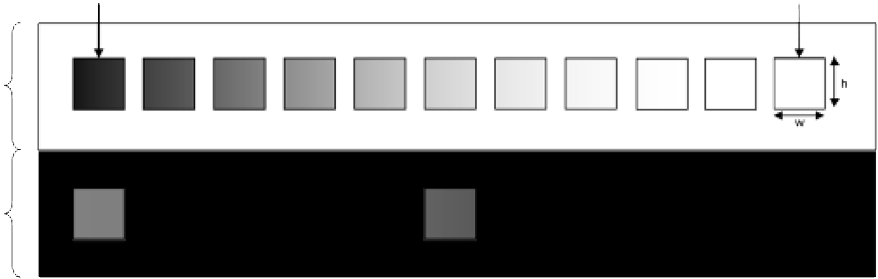

Characterization data set is created by printing tints of the desired color over white and black ink and on a given substrate

| Solid | Substrate | |||||

| Substrate |  |

|||||

| Region printed w. Black | ||||||

This quantifies the opacity of the ink, which is a major variable related to color reproduction.

Conformance Levels:

| measurement type | CxF/X-4 | CxF/X-4a | CxF/X-4b |

| solid ink printed on the substrate | required | required | required |

| tints of ink printed on the substrate | 3 minimum, 11 recommended | 3 minimum, 11 recommended | not required |

| tints of ink printed on black background | 3 minimum | not required | not required |

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.