April 22, 2024

Veoria DeltaOne and DeltaWeb

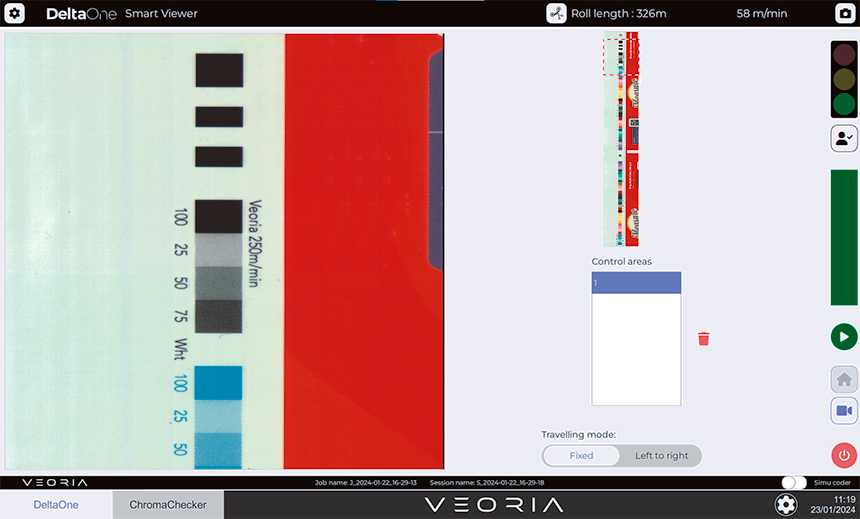

Veoria inline spectrophotometers are custom-designed to meet the color challenges of the printing industry.

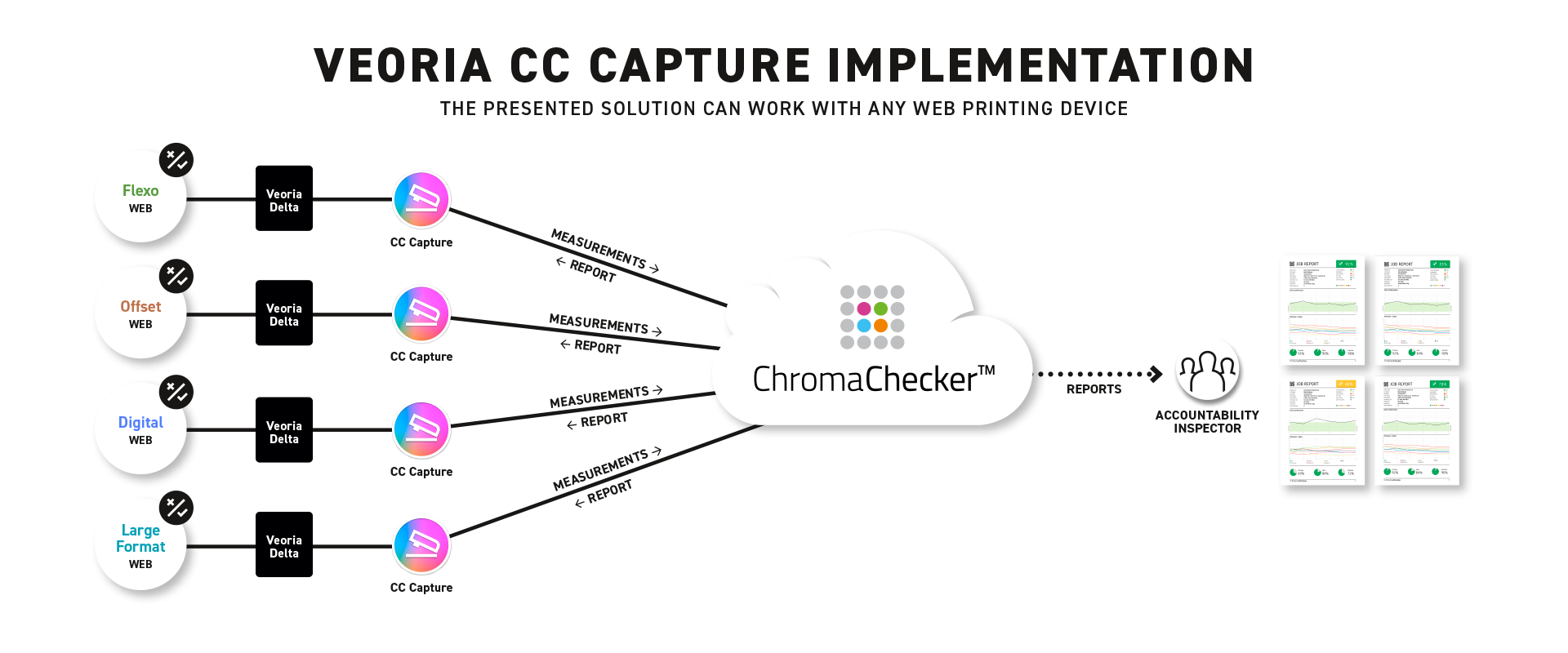

The solution can work with any Web printing device: Flexographic, Web Offset, Web Digital, or Web Large format.

|

|

|

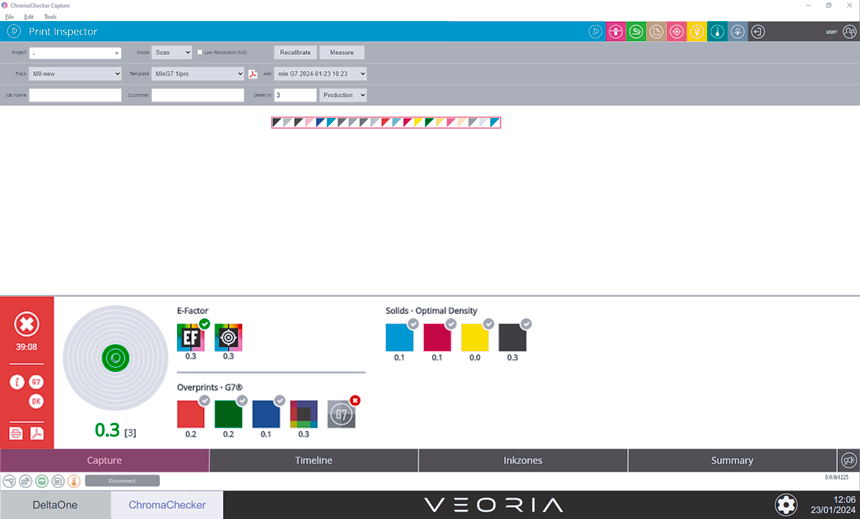

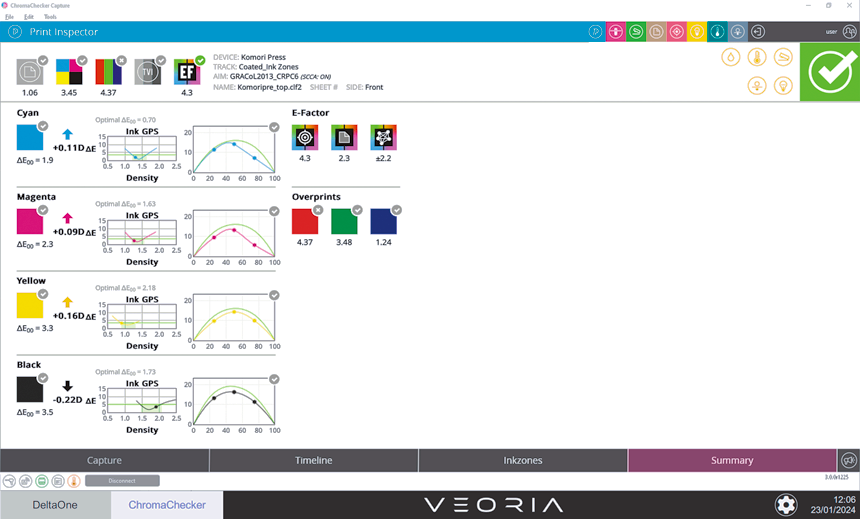

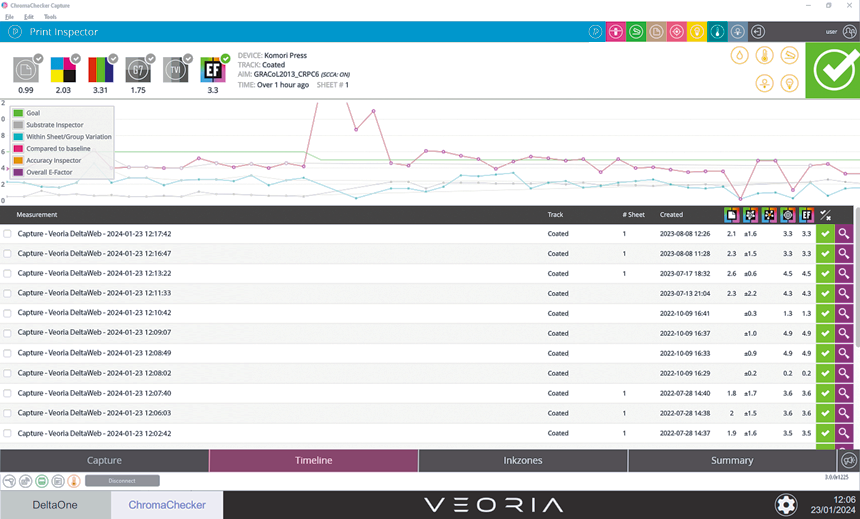

CC Capture Veoria Implementation features and hardware comparison:

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.