G7 Press Calibration

ChromaChecker Print Inspector has a built-in state-of-art G7™ engine which is very accurate and very flexible unlike other options on the market.

- Calibration from production - no need for dedicated press runs, build G7 curves from salable print runs

- No need for a P2P target, the system supports smaller, smarter targets that can be included in live jobs

- Built-in variation analysis- any time a measured target has identical patch values, ChromaChecker assesses the variation between all like patches

- Primaries and overprint color and density evaluation against any reference condition

- Dot gain, TVI assessment

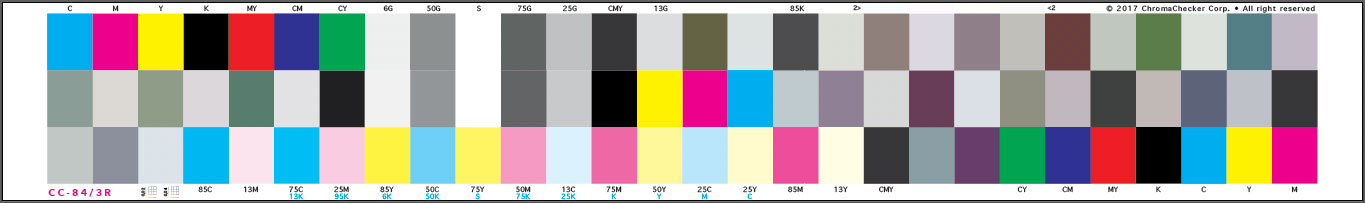

Calibrate with CC-84

CC-84 contains enough patches to evaluate variations, check primaries and overprints, evaluate tonality and gray balance and includes gray-finder patches necessary to iterate G7 compensation curves that are accurate for most workflows. The target is available in a number of patch sizes and layouts making it easy to include with live jobs.

Verify with Minimal G7

This is a small control strip (21 patches only) that analyzes G7 the condition of the printer. There are situations where there is no room on the sheet for P2P (300 patches) or even CC-84 but enough to fit the Minimal G7 target.

P2P, VI-816, CC-400, IT8.7/5 , TC1617...

Chromachecker G7™ engine works with any control strip that contains required G7 patches. The user may decide which control strip is the most practical for their hardware configuration

Calibration Steps

- Print selected Control Strip ( e.g. CC-84)

- Measure it with CC Capture or any other measurement solution that is already integrated with your production chain (use Uploader for 3rd party applications to automatically upload measurements to Print Inspector Track)

- Qualify for G7 calibration (Primaries and Secondaries have to match G7 requirements)

- Generate G7 Curves, select the required file format, and download

- Install in your Printing System

- Print CC-84 or minimal G7 to evaluate calibration results

Automate G7 curve creation and application to a workflow using Color Server

Chromachecker supports a solution where CC Capture is used to create and download compensation curves to a hot folder if the printer fails G7, then a color server such as Alwan ColorHub will automatically apply the new curves to the next file run through the workflow.

Video

-

This tutorial shows how to take uploaded measurement data to create a iterated press curve without having to complete a dedicated press run.

-

The tutorial covers how to configure ChromaChecker to generate G7 Curves for Digital Presses. It's a step-by-step that shows how to configure the ChromaChecker cloud for automation and how to use ChromaChecker Capture to evaluate the existing G7 condition of a press and generate a curve to bring a press into G7 conformance.

-

This tutorial shows you how to generate a G7 Press curve without having to complete a dedicated press run.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.