Minimal G7 Control Strip

![]()

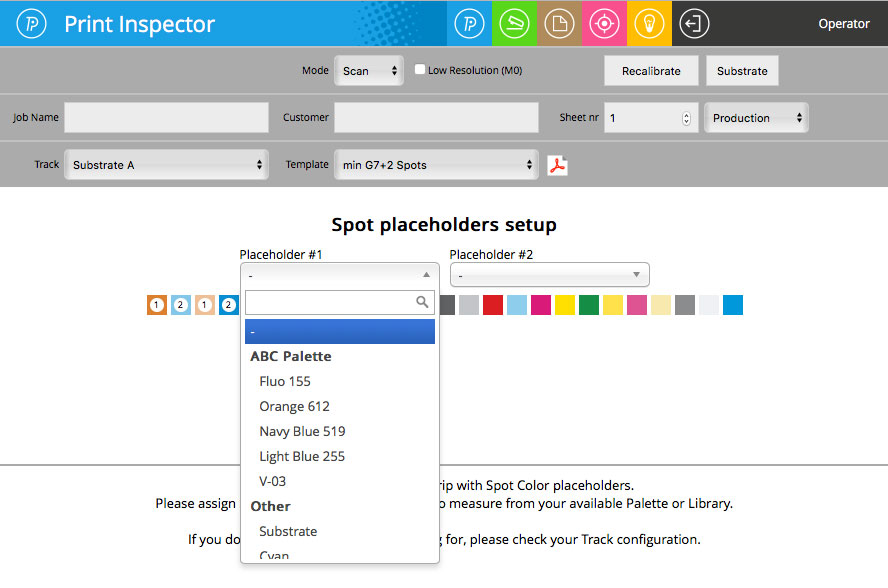

This control strip contains 21 patches for G7 conformance plus very basic TVI and overprints analysis.

Assessing an offset press used to require a dedicated press run which is very expensive, and is often not indicative of actual day-to-day production. For these reasons, we have developed multiple procedures to assess an offset press during live production. We have designed small control strips that can be placed within live work.

Minimal G7 inline with live work, it is also possible to include our CC84 target that can be used to iterate G7 curves from this data.

Three-row compact version (Minimal G7 -3R)

When using a handheld instrument with a scan option like X-Rite eXact Scan or Techkon SpectroDens or using other instruments with a small aperture, it is possible to reduce strip width to 3-4 mm (1.5 / 2mm instrument aperture required). If you are using a different instrument contact the vendor for detailed information.

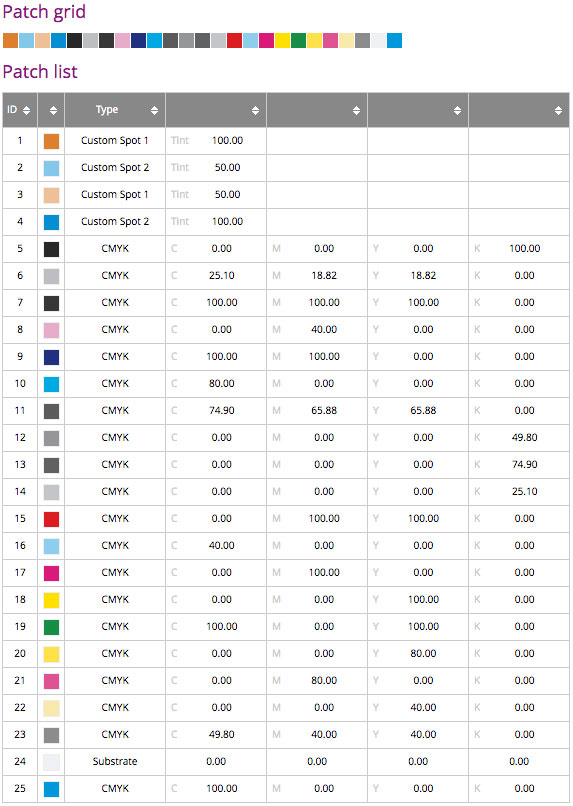

Extended Minimal G7+Spot placeholders

Minimal G7 can be adopted to CMYK + SPOTs job very easily. This allows a user to have one color bar that works with any print process that includes CMYK and or any two spot colors. No need to use multiple color bars with the specific combinations of spot colors. This provides a company to use one color bar to represent any combination of CMYK and or any two spot colors. If the job is run without spot, the Capture operator defines the two spot placeholder positions as substrate patches (since they will be blank since no spot was used). Use Capture Inspector to add additional patches. In the following example four spot placeholders were added (two solids and two 50% tints/ Custom Spot 1 and Custom Spot 2).

Custom Spot is a placeholder - the user can assign any spot color from the library when working with CC Capture. It is a very flexible way that reduces time and effort.

Here you can find a step-by-step procedure on how to add placeholder patches to Minimal G7

finally, the operator will be asked to assign placeholder patches with spot color references stored in Color Library/Palette.

Such a control strip can work with any spots without the need to recreate each time. The operator may want to skip one or more placeholders using a DUD selection.

Minimal G7 3R

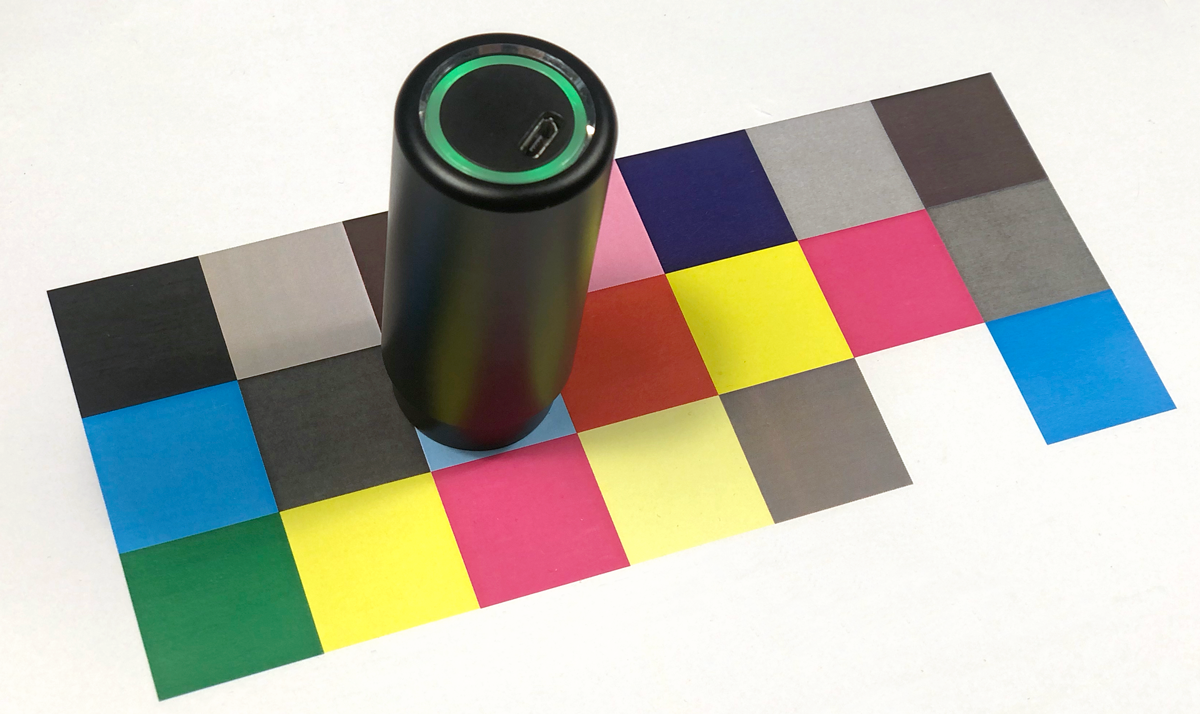

There are situations where we need a 3-row version. For example, i1iO with i1Pro 3 Plus requires large patches (16x16 mm or 16 x 20 mm). Also, some pocket instruments can measure control strips but the patch size has to be large.

Imagine a scenario when you need to evaluate the printing process (G7 or TVI) when printed on a foil substrate or substrate with some surface effects. A regular 0/45 spectrophotometer will not work properly and a spherical one has to be used instead. You may need to use for example Spectro 1 Pro Bridge that is D/0° SPIN and give an opportunity to measure Actual (Pure) Color without sheen effect. But this instrument has an 8 mm aperture and a minimal patch size is 10x10 mm but due to physical shape patch size needs to be larger to make it easy to measure.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.