January 19, 2023

Brand Definition and Requirements 1

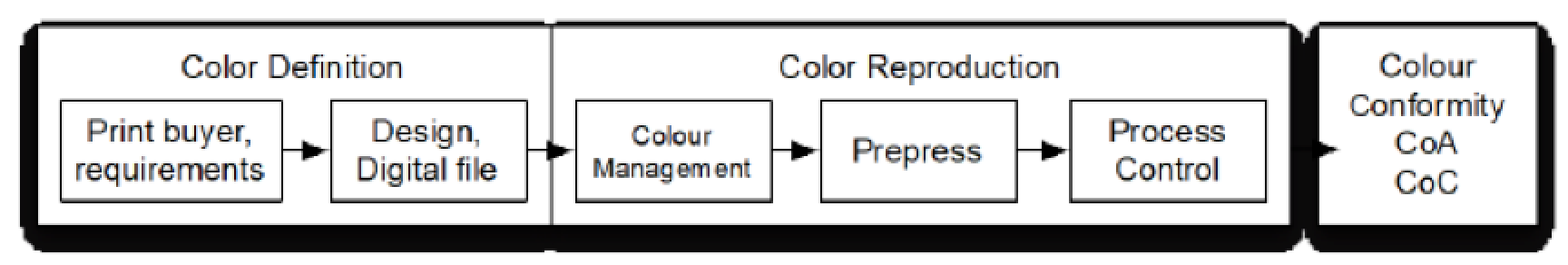

The purpose of this audit is to help the brand manager specify the color definition for their suppliers clearly in order for the suppliers to be able to achieve the brand manager expectations.

- All brand personnel involved in making critical color communications and

decisions should complete and pass color vision tests

** Munsell Hue 100 test is available for rent from ChromaChecker.com. Upon individual completion, document scores inside Accountability Inspector for each user.

Digital version of the color vision test: http://www.colormunki.com/game/huetest_kiosk - Viewing conditions compliant with ISO 3664:2009

ChromaChecker Lighting Inspector provides the ability to assess viewing conditions using an i1, How To:

https://vimeo.com/353777479 - Instrument and settings for measurement verification compliant with ISO 13655:2009

ChromaChecker Instrument Inspector allows users to assess instrument to ensure instrument is precise.

https://vimeo.com/249081563 - Specification of Expectations for process and spot color values and utilizing DE2000 and CRF 95th per (E-Factor). This is the online exercise to allow a company to define their expectations.

Process Color Expectation Exercise (E-Factor): https://chromachecker.com/cee/en/manual

Spot Color Exercise (delta E): https://chromachecker.com/colorexercise/en/start - Knowledge of G7 calibration method and its applications

ChromaChecker provides numerous G7 tools to apply G7 methodologies to your print process, How To:

https://chromachecker.com/other_tools/en/manual/g7_curve - Knowledge of SCCA method and its applications

ChromaChecker provides automatic SCCA calculations to incoming measurement files, and for manual calculations, ChromaChecker has a manual tool to calculate SCCA reference conditions.

- CMYK aims, ICC Profile, and / or CRPCs (Characterized Reference Printing Conditions)

ChromaChecker has built in standard process control aims and ICC profiles, and provides the ability to assess ICC Profiles and CRPC data using ICC Profile Inspector, here is the How to use ICC Profile Inspector:

https://vimeo.com/336469324 - Spot colors, Brand colors, and CxF/X aims

ChromaChecker provides extensive spot color capabilities to determine aims for expectations, and set tolerances and provides tools to measure and assess spot colors very fast and easy.

https://chromachecker.com/other_tools/en/manual/color_inspector - Design guide - overview of objectives

ChromaChecker provides tools to visually define the desired expectations for color matching. - Print product structural requirements

- Print Sequence - (creating an overprint simulation profile)

- Die line(s) indications

- Defining Minimum requirements for print and reporting

- Certificate of Analysis (CoA) and Certificate of Conformance (CoC) testing and reporting requirements

ChromaChecker provides the ability to set the tolerances for both spot and process colors using one number to provide the details for a Certificate of Conformance. - Standard operating procedures (SOP) documenting all procedures, and equipment upgrades

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.