How Does It Work?

Does my instrument work normally?

What is "normal?" – this is a fundamental question to understand the accuracy of your device.

Different instruments measure the same color patch differently. Different instruments use different sources of radiation, different monochromators, and different sensors. There are different spectral ranges, algorithms ... Even different instruments from the same vendor can measure differently.

Laboratory indexes such as inter-instrument agreement is typically based on 12 BCRA standards - but in production we need instruments to measure not 12 ceramic tiles but millions of printed patches. What is interesting is not the manufacturer declared value, but the results measured with our own instruments.

Is my instrument stable and repeatable? Following the manufacturers calibration procedure which requires the spectral measurement on the white ceramic tile provided by the instrument vendor should provide a stable result within the manufacturers specification. But, if the tile is not properly cleaned before calibration, then readings can produce inaccurate results with visible differences.

Case study:

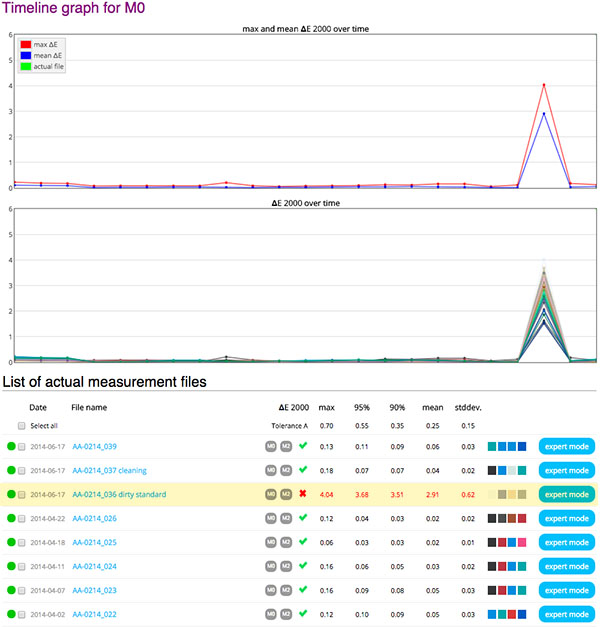

An X-Rite Isis with small piece of paper dropped accidentally on calibration plaque. Wrong calibration in this case gives maximum deviation = 4, and mean deviation = 3. Potential error depends on size and color of "foreign body".

There are many causes for an instrument to lose accuracy - e.i. dropped instrument on the floor, press powder going inside optics, or use the instrument at the wrong ambient temperature... and many more potential causes.

Do all my instruments measure color the same way?

Your instrument "normal" is not an absolute value – two different instruments can have different "normals." For more information about potential results go here.

ChromaChecker Instrument Inspector answer:

For simple, routine instrument verification the PASS/FAIL test compares current measurement to your reference – (the initially created baseline).

If the test passes it means that your instrument is measuring "normal" – results are within your tolerances. Operator knows that measurements are predictable and that fact is documented.

ChromaChecker enables users to compare baselines - and thanks to this unique feature, measurements from different instruments can be compared. If you have several instruments you can compare them also. For multiple locations, the "Partner" option enables to share your baselines with other users.

The Compare Function allows you to pick up to five baselines from five different instruments to compare how the instruments measure the same color differently.

Targets and Baselines

ChromaChecker™ Instrument Inspector is based on measurement of dedicated test chart - Target. Currently, we offer three variants of this tool. About Targets read more here.

Baseline - averaged set of an Instruments measurements for a given Target. Whenever you want to judge a instrument, compare new measurements of the given target against the instrument's baseline. Learn more about baselines here.

Instrument Inspector Manual

To use Instrument Inspector one of ChromaChecker™ Instrument Inspector

Targets is required. To buy visit to IDEAlliance

![]()

Instrument Inspector – How does it work?

Why use Instrument Inspector?

Instrument Inspector Target

Baselines and data averaging

How to start-up?

Instrument Inspector menus - how to navigate?

Easy mode / Expert mode

Data sharing

Instrument's comparison

Instrument’s compatibility list

General rules

FAQ

Tricks and Tips

![]()

Supported Instruments – manuals

X-Rite i1 Pro 1

X-Ritei1 Pro 2

X-Rite i1iO

X-Rite iSis

X-Rite DTP-70

X-Rite Intelitrax

X-Rite eXact – manual mode

X-Rite eXact – scan mode

X-Rite 530

X-Rite 939

X-Rite SpectroEye & other from X-Rite

Techkon Instruments

Barbieri instruments